Pinion have crammed a motor into the gearbox. Here’s details of the Pinion E-Drive System AKA Pinion Motor.Gearbox.Unit (MGU).

TLDR: Pinion E-Drive System

- 85Nm (but “in the first four gears, the MGU delivers up to 160 Nm of torque to the rear wheel”)

- 600 watts peak power

- Max. support up to 400%

- Four riding modes (Eco, Fly, Flow, Flex)

- Batteries: ‘Ultracore’ 470, 720 and 960

- Range extender option

- 9 or 12 gears (E1.9 and E1.12 respectively)

- Up to 600% gear range

- “From 9th gear onwards the system is almost silent”

- Electric shifting

- Semi-automatic shifting options

- “Smart.Shift System can shift while riding, while being stationary and under load! It can shift for you, it can shift manually, it can instantly shift multiple gears at once and it’s virtually maintenance free.”

- Sealed against water and dirt

- OIl change every 10,000km

- No derailleur, no cassette, no chain (it’s belt drive)

- Greatly reduced unsprung mass (more than 500g lighter at rear wheel)

- Made in Germany

Pinion press release in full:

WORLD’S FIRST. MOTOR AND GEARBOX. FINALLY UNITED.

The drivetrain is the heart of an e-bike. Until now, this has consisted of two separate systems – a gearshift and a motor, which usually come from different manufacturers and yet somehow have to work together. The consequences are bad shifting performance, high wear, followed by high maintenance with enormous costs. The Pinion Motor.Gearbox.Unit (MGU) is here to change that.

Pinion brings together what belongs together. The Pinion MGU is the e-bike technology of the next generation – because it combines motor and gearshift into one unit. It combines a powerful electric motor with proven Pinion gearbox technology and electric shifting of up to 12 gears in a compact package to create a completely new drive system for e-bikes. Motor and gearbox are optimally matched and work together like never before. Pinion motor-gearbox units offer durable shifting and motor performance at the highest level. Designed to work worry-free and reliably, with no significant wear and minimal maintenance. One oil change every 10,000 km! That’s it!

As a world first, the Pinion E-Drive System with its core Motor.Gearbox.Unit (MGU) will be presented to the public for the first time at Eurobike 2023. The following launch partner brands are offering e-bikes with the Pinion E-Drive System in various categories for the 2024 model year: Rotwild, Simplon and Bulls are launching unique E-MTBs with perfectly balanced weight distribution and impressive performance. Kettler, Flyer, Tout Terrain, Pegasus, Zemo and I:SY will offer e-trekking bikes, e- cargo bikes as well as e-compact bikes. Speed pedelecs with Pinion E-LINES series MGUs are in the lineup of various brands

THE HEART OF THE SYSTEM – THE PINION MGU

The Pinion MGU combines a wear-free electric motor and the innovative Pinion gearbox with 9 or 12 gears in a compact all- in-one package of comparable size and weight to current mid-mounted motors with separate gear shifting. Controlled by electric shifting and powered by Pinion’s own hardware and software, the Pinion MGU is the heart of a completely new drive system for e-bikes.

The internal development of all integrated electronic components is the key to ensuring that all parts of the system work together as one unit to deliver lightning-fast, crisp shifting in all situations and on all terrain. The Pinion MGU operates reliably over the long term with no significant wear. The MGU is located centrally and low in the bottom bracket area, resulting in optimal weight distribution of the e-bike. The elimination of the external rear derailleur and cassette is also accompanied by drastically reduced maintenance. An MGU and its integrated shifting technology operates virtually wear-free and requires nothing more than an oil change every 10,000 kilometers. In addition, the system significantly reduces the unsprung mass at the rear wheel, which results in better suspension performance and ultimately leads to greater comfort and traction.

The roots of the motor inside the Pinion MGU is a state-of-the-art e-machine for industrial applications, manufactured in Germany and redesigned for use in an e-bike. The motor offers extremely high efficiency and a highly dynamic power density without sacrificing shifting performance.

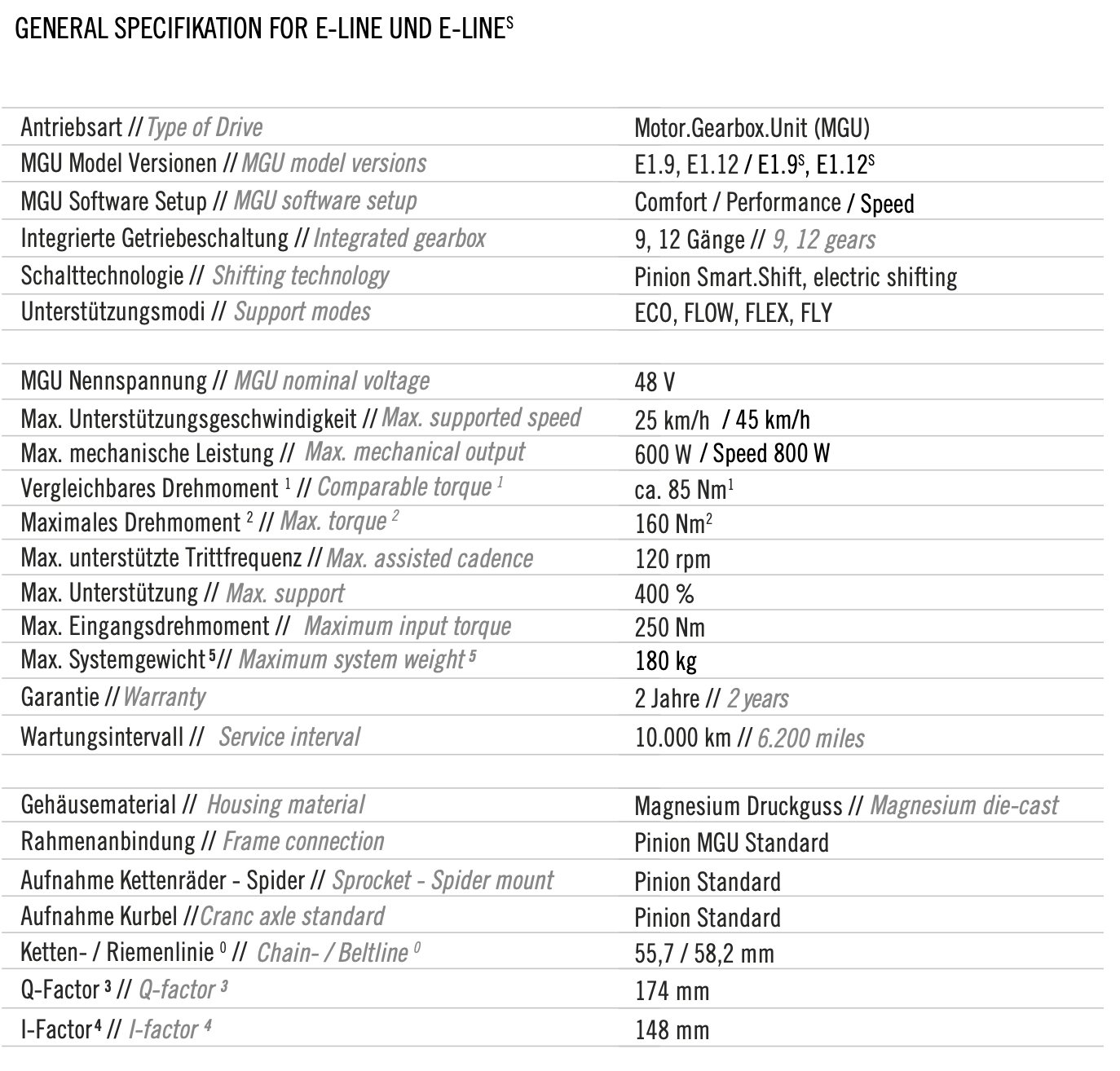

All MGU versions are based on 48 volt technology and offer approximately 85 Nm of torque compared to conventional motors without integrated gearbox. However, due to the integrated gearbox, the output shaft values are not directly comparable with those of ordinary mid-motors. In the first four gears, the MGU delivers up to 160 Nm of torque to the rear wheel. The peak power is 600 watts, and 800 watts for the S-pedelec versions. The maximum support is up to 400%, and that at a permissible input torque of up to 250 Nm.

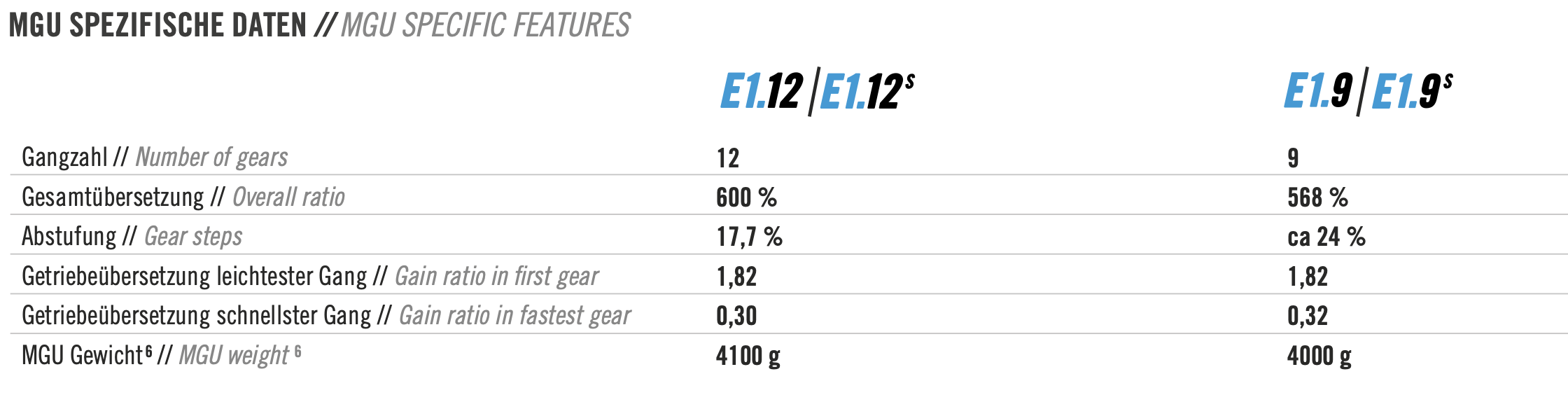

Thanks to its operational design, a Pinion gearbox offers more reliable shifting than conventional bicycle derailleurs and is far better equipped to handle the high loads imposed by an e-bike motor. Proven for more than a decade and used by over 100 bicycle manufacturers, the technology is reliable, durable and needs extremely low maintenance. There is no rear derailleur that can get out of line or break off. In addition, gearboxes are sealed against water and dirt. Based on proven automotive gearbox technology, Pinion gearboxes rely on highly efficient spur gearing with two sets of gears connected in series. Depending on the configuration, the gearbox offers 9 or 12 speed in the MGU with an unmatched range of up to 600%.

Using a modular approach towards designing the Pinion E-Drive System allowed Pinion to develop several distinct configurations and versions of the MGU. Depending on the individual use-case, each version has either 9 or 12 gears and is actuated by electric shifting. Furthermore, the software of the system comes in two distinct base tunes – ‘Comfort’ for efficient and harmonic commuting as well as reliable long-distance touring and ‘Performance’ for super-agile off-road riding. An additional dedicated version for Speed-Pedelecs rounds out the offer. Each version comes with a different motor and gearbox configuration featuring individual tunes and settings perfectly tailored to the intended use. MGUs are available in the Pinion E-Line, as E1.12 and E1.9 versions and as E-Speed versions E1.12S and E1.9S.

SEMI-AUTOMATIC ELECTRIC SHIFTING WITH PINION SMART.SHIFT FUNCTIONALITY

Next to offering near-instant engagement at the pedals and an natural ride-feel thanks to the motor and gearbox working in harmony, the Pinion E-Drive System also includes semi-automatic shifting capability. Pre.Select allows the system to automatically shift into the perfect gear for the bike’s speed when coasting downhill, providing the rider with the right gear to get back onto the pedals without having to frantically shift up or down first. And then there is Start.Select. When, for example, a cyclist stops at a traffic light, the MGU can automatically shift into a preselected starting gear. The days of awkwardly trying to get the bike going in the wrong gear are officially over. The MGU and its Smart.Shift System can shift while riding, while being stationary and under load. It can shift for its rider, it can shift manually, it can instantly shift multiple gears at once and its virtually maintenance free.

HMI AND SYSTEMINTEGRATION

Thanks to FIT as a system integration partner, the Pinion E-Drive System offers bicycle manufacturers a high degree of modularity as well as a proven and reliable service infrastructure. The FIT ecosystem offers various interfaces, displays and batteries that can be combined in a variety of ways to create a customized e-bike tailored to the specific application. With a focus on connectivity and individual ease of use, the FIT E-Bike Control App allows the pre-configured MGU setups of all support modes to be customized according to personal preferences.

MADE IN GERMANY

All Pinion units are developed in Germany and assembled at the company’s headquarters near Stuttgart by experienced employees. After completion, each MGU passes an extensive “end-of-line” test run. Here, the quality, functionality and load resistance of the motor-gearbox units are ensured before delivery. The majority of all components belonging to the MGU; from the electric motor to the gearbox and gearing components are produced by our qualified partners in Germany and other European countries. The Pinion MGU project is funded by the German Federal Ministry of Economics and Climate Protection on the basis of a resolution of the German Bundestag.