Home › Forums › Chat Forum › Cheap 3d printer kits – Experiences?

- This topic has 690 replies, 36 voices, and was last updated 4 years ago by zilog6128.

-

Cheap 3d printer kits – Experiences?

-

AlexSimonFull MemberPosted 6 years ago

siwhite – that benchy looks impressive for a budget printer. Nice job!

Nice saddle too – Don’t be surprised if he doesn’t take to the balance bike straight away. Mine didn’t get it for 6 months before suddenly rocketing along on it.

morphioFree MemberPosted 6 years agoJust printed on default settings from Slic3r PE, didn’t change anything.

Prusa PLA 0.15 layer height, 0.4 nozzle, 215 nozzle, 60 bed. 2h20min

Taken at angles to show layers as badly as possible:

I guess next step is start learning what/how to tune for better results!

bigdeanFree MemberPosted 6 years agoThe home brew frankenprinter has been fired up again after buying some replacement drivers.

Printing some top tube sections

There are some good quality print being shown on here, I really must tighten up the hot end on mine as get a bit of leakage and blobs in the print.

motivforzFree MemberPosted 6 years agoDoes anybody have the time/capacity to print a couple of parts for me for some beer tokens to help pay for their hobby? I’ve got a couple of bits I’d like printing but the online quote houses are hella pricy! Any black tough ish material would be great – ABS or similar. They’re a couple of kit car brackets / trims.

WorldClassAccidentFree MemberPosted 6 years agoI only have clear slightly flexy filament at the moment but am happy to print some for you to check the size/fit if you want. Email me the STL, email in profile.

Example of some chassis plates I printed for my car.

20180508_194703 by WCA![/url], on Flickrstumpy01Full MemberPosted 6 years ago

20180508_194703 by WCA![/url], on Flickrstumpy01Full MemberPosted 6 years ago^^^ that looks great. I love seeing these printers used for practical things. One of my colleagues is using his for a beekeeping project, so always brings in new test pieces to show me.

His latest one is setting the printer to pause mid print, so he could pop a nut into a hole & resume print to encapsulate the nut within the part – it worked really well, although he thinks next time, it would be better to pre-heat the nut by leaving it on the print bed, while the print is running.Anyway – I’ve been doing a mix of practical stuff & not so practical stuff. Over the past few months I’ve done a Nespresso pod holder for my Wife’s coffee machine (no pics uploaded yet), a Maxle boost spacer for my mates Thule bike rack, some new mounts fo a kitchen drawer front because the existing bracket decided to disintegrate one evening, some pan lid holders for the kitchen door.

I printed some carabiners the other day for my nephews. I was visiting at the weekend & they seem to be really interested in how the printer works, so I thought a practical print might interest them:

IMG_20180729_212340 by STW stumpy01[/url], on Flickr

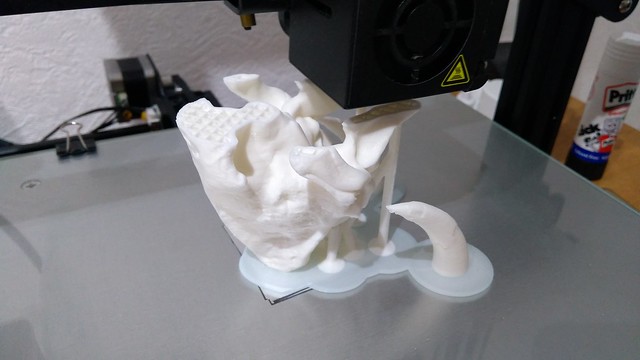

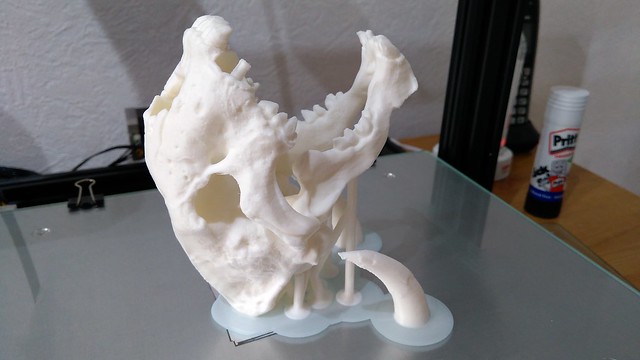

IMG_20180729_212340 by STW stumpy01[/url], on FlickrThen I got carried away & decided to print something completely pointless, but would test out the capabilities of my printer a bit, so did this – please excuse the mass of pics!:

IMG_20180728_093358 by STW stumpy01[/url], on Flickr

IMG_20180728_093358 by STW stumpy01[/url], on Flickr IMG_20180728_111857 by STW stumpy01[/url], on Flickr

IMG_20180728_111857 by STW stumpy01[/url], on Flickr IMG_20180728_134826 by STW stumpy01[/url], on Flickr

IMG_20180728_134826 by STW stumpy01[/url], on Flickr IMG_20180728_191905 by STW stumpy01[/url], on Flickr

IMG_20180728_191905 by STW stumpy01[/url], on Flickr IMG_20180729_213842 by STW stumpy01[/url], on Flickr

IMG_20180729_213842 by STW stumpy01[/url], on FlickrI need to print out a stand for it at some point….!

AlexSimonFull MemberPosted 6 years ago9 months on and I haven’t made much progress with the 3D printed Root 3 CNC dueto buying a van to convert into a camper, but at least it’s assembled and wired – just need to add the Arduino now!

I’ve put holes in the base so it can hang up on the shed wall.

It’s also got some bolts that fix it to insert nuts in the workbench.

stumpy01Full MemberPosted 6 years agoNice! Only the other day I was looking at the MPCNC on Thingiverse & wondering how you got on with it. Was it PETG you ended up using?

Any idea how much the total spend is going to be? I still fancy doing one at some stage, although at the moment haven’t moved away from printing PLA and not sure how successful it would be in that material.

While my printer is working well with PLA, it seems like a risk to bugger about with it & have potential issues.We have used the Ultimaker version of PETG at work (CPE) with definitely mixed results. It is quite hard to get a nice surface finish with it & there is normally a fair bit of blobbing & clean-up required. Settings are mostly stock though, so it probably needs a tweak.

Now you’ve got the printed parts sorted, are you actually using the printer for anything?

I’m currently designing up a tape cutting fixture to cut gorilla tape (or whatever) to a set width for tubeless conversion; the aim is to make it adjustable from 22-30mm in 1mm steps.

My first iteration proved the principle, but was a bit rough & ready.

The second iteration refined it, but I cut my finger open while installing the stanley blade, so I decided a version 3 was probably required with a nod to user safety!

Version 3 has some features to protect the user from the blade, but there are a few parts I am not happy with, so hopefully with one more bit of re-design it will be finished.AlexSimonFull MemberPosted 6 years agoYes, I used PETG. I printed in the shed in winter so got some warping, but it was fine once I switched to using Elmer’s Purple Glue on PEI.

To be honest, the only reason for using PETG is temperature resistance. It gets hot in the shed in summer and the motors will run a little hot. Many people use PLA just fine.Total cost is £490 About £100 more than I was hoping for. I needed an extra roll of filament and the stainless hardware was much more expensive than I guessed. The other surprise was the cost of the Linear Rails.

I’ve already bought everything. Just need to wire up the Arduino and fit the belts.

I will have to make a separate box for the electronics with a connector to the main unit. Haven’t really got a plan for that yet.

MPCNC is much more supported than this, with a larger community, but I was never convinced it was strong enough for birch ply and aluminium. Seems some do have success though!

This seems very sturdy and it’s pretty big (750×550 cutting area iirc).—–

We use the 3D printer occasionally and it’s really useful when we do. We’ve already used it on the van conversion plus my son has printed a few useful storage bits and bobs. We don’t print objects d’art/figures or anything like that though.

We also got a commission for another 3D relief map from someone on here, so my son is doing that – just the osmo to do on the wooden frame and that’s finished.We do have some plans to print a board game at some point, but for now all attention is on the van as it’s a 6-month project at least.

zilog6128Full MemberPosted 6 years agoAnyone know owt about slightly less cheap 3d printers? I have a few work uses in mind (although nothing that’s going to really make me any money!) as well as wanting one for general mucking about. Like the sound of SLA & really like the look of the Form 2 from FormLabs, although even 2nd hand they are still £2k+. Form 1 available a bit cheaper 2nd hand but not as good obviously!

Any other SLA or other technology printers worth looking at? Don’t really want to go down the older, extruder style tech route unless there’s a more pro-level machine that needs less sodding about, finishing, etc?

AlexSimonFull MemberPosted 6 years agoPrusa just launched an SLA printer (they bought a company and then refined the design).

https://www.prusaprinters.org/introducing-original-prusa-sl1-open-source-sla-3d-printer-by-josef-prusa/I have to say though, this

Don’t really want to go down the older, extruder style tech route

Doesn’t really fit with reality. There are a lot of advantages to FDM that SLA doesn’t have. I’ve always liked Lulzbot as a company if you want to look at some prosumer models.

zilog6128Full MemberPosted 6 years agoThanks, I’ll take a look at those! Happily admit I know very little about these things, SLA appealed though due to the precision & smooth finish of the objects.

MilkieFree MemberPosted 6 years agoAny other SLA or other technology printers worth looking at? Don’t really want to go down the older, extruder style tech route unless there’s a more pro-level machine that needs less sodding about, finishing, etc?

Have a look at SLS printers, but you won’t find one for home/desktop use. SLA looks messy as I think you have to soak the object in a fluid after its printed.

Made a quick release jig for sharpening some cylinders on a lathe, it worked well, better than I expected.

Noticed the Creality printers seem quite cheap atm through HDUK.

Currently building up the courage to strip down my machine down, replace the cheap bearings and rods with more precise items, but it seems quite daunting!

zilog6128Full MemberPosted 6 years agoFunnily enough it was seeing that Creality machine that got me thinking.

Wish I had £10k+ to waste on the forthcoming SLS machine from FormLabs, that does sound really good!

AlexSimonFull MemberPosted 6 years agoMost people who want something just above the cheap chinese level buy a Prusa mkii or mkiii.

You can get them in kit form or fully built and with multi-material additions.

Short of many thousands though – they all need a bit of TLCand knowledge to get good results from.

davea37Full MemberPosted 6 years agoReading this thread was an expensive choice! GB have the Creality Ender 3 on offer so I’ve just ordered one for myself as an early Christmas present. Whether it’ll actually arrive before Christmas is another matter of course…

AlexSimonFull MemberPosted 6 years agoCool – be sure to post your exploits!

Half the price I paid for my CR-10.

Mine arrived in 20 days, but ymmv – some people have waited ages.stumpy01Full MemberPosted 6 years agoMy Cr10-mini arrived in only 6 days from Gearbest!

As for higher end printers, we have an Ultimaker 3 Extended at work.

It does produce good results and it’s dual extruders are great for printing with pva support material, but it is far from ‘fiddle’ free, the user interface can be frustrating and support from Uktimaker hasn’t been brilliant – we’ve just had a printcore fail through what appears to be a bit of a poor design and they’ve basically told us the entire print core is a wear and tear item, so tough. And this is a £3.5k machine that has seen only moderate use in an office environment.

kimbersFull MemberPosted 6 years agothis looks like a good deal? however I know nothing about 3d printers

early xmas present to myself?

https://www.gearbest.com/3d-printers-3d-printer-kits/pp_1845899.html?utm_source=tt_de&aid=171752

AlexSimonFull MemberPosted 6 years agoYep it’s a good deal. Plenty of youtube reviews.

On Aliexpress they are claiming to ship it for the same price from within the UK. Don’t know true it is though. This is the Creality official shop. They emailed me this morning:

https://www.aliexpress.com/store/product/cheap-3d-printer-Creality-Ender3-Ender-3X-Upgraded-Tempered-Glass-Optional-V-slot-Resume-Power-Failure/2846085_32858931045.html?spm=a2g1y.promotion-20181111.promotePruductList_6530699.0NorthwindFull MemberPosted 6 years agoThe ender-2 is pisstakingly cheap now, these single-sider designs are never as good as a well set up prusa-style or delta but they’re so cheap, and simple, basically the most “consumer” printers out there at a low price. Can’t say I’m not tempted even though I should actually fix the Tarantula instead

AlexSimonFull MemberPosted 6 years agoThe Ender 3 at £134 is a ‘normal size’ Bowden tubed, i3-style framed printer Northwind.

the Ender2 is the single armed one. That’s £118 now!

the CR-10 is still £260ish so I don’t know now they do the Ender 3 for only £134. It’s a kit I guess

NorthwindFull MemberPosted 6 years agoYeah, I was just adding that the ender-2 is another good option. And the -4 looks like it could be an excellent step above the CR-10 and ender-3. Things are really moving…

AlexSimonFull MemberPosted 6 years agoI was amazed at what results my mate is getting from a modified Anet A8. Paid virtually nowt and the results are pretty much perfect. He just did the same mods that everyone recommends. He’s got no kids though – so a lot more time than me to tinker. I think they might have been under £100 at some point (only £103 now).

I don’t see why your Tarantula couldn’t be as good with a bit of effort.stumpy01Full MemberPosted 6 years agothe results are pretty much perfect. He just did the same mods that everyone recommends. He’s got no kids though – so a lot more time than me to tinker.

Has he improved part cooling with a fang?

I think that apart from a day spent doing some proper experiments and tests to optimise the printer, the one thing I really want to get sorted is improved part cooling with a fang. I reckon this is a bit of a weak point on the Creality printers…

NorthwindFull MemberPosted 6 years agoTBH most cheaper printers don’t really have good enough part cooling for ABS, it’s pretty much always worth adding something, even if just a crude always-on fan (my tarantula has a nice directed setup with a fat 40mm PC fan on, up til then I just couldn’t print fine detail in ABS, it’d always slump even at dead slow pace.

AlexSimonFull MemberPosted 6 years agoNot sure stumpy – I’ll ask. The Anet A8 is a direct extruder (rather than a bowden tube) so that area will be bulkier.

zilog6128Full MemberPosted 6 years agoHad a look online at the Lulzbot printers mentioned earlier over the weekend. They look really good, level of detail using the micro extruder head looks fantastic. Dual extruder option featuring soluble supports looks very handy also. Anyone used one of these? There is a used one on eBay at the moment, seems quite cheap though (a grand off the new price) given the seller claims it is as good as new.

AlexSimonFull MemberPosted 6 years agoNo experience, just really like the guys in charge of the company. Totally Open Source (and big advocates), approachable and they sponsor YouTube legend James Bruton from XRobots (i’ve a feeling he used to work there, but can’t get confirmation from a quick google):

https://www.youtube.com/channel/UCUbDcUPed50Y_7KmfCXKohAUnfortunately for the £1000-2000 machines, the Prusa i3 mkii and mkiii have made them a bit redundant, which is a bit of a shame.

It’s only worth paying more if you’re a company who just want it to print no matter what, or you have a specific requirement that the Prusa doesn’t do – Build volume/heated enclosure/speed/etc.AlexSimonFull MemberPosted 6 years agoAnother company I like:

https://www.bcn3dtechnologies.com(I guess I’ve found out about all these through Open Source links – they all use E3D hot ends, CURA/Slic3r and publish their files – in short they are part of the RepRap community).

zilog6128Full MemberPosted 6 years agoUnfortunately for the £1000-2000 machines, the Prusa i3 mkii and mkiii have made them a bit redundant, which is a bit of a shame.

Spent the last few days having a dig around, you seem to be right! For under £600 for the kit it’s less than half the price of a 2nd hand Taz 6 (which does look very nice to be fair). Just about comfortable with that kind of money for a punt/toe in the water. The forthcoming multi-material head looks like fun too.

Worth getting any filament apart from the included PSA? PETG maybe (sounds like a more useful material?) Don’t fancy using ABS right away due to the apparent smell.

NorthwindFull MemberPosted 6 years agoABS doesn’t smell too bad. People often say it’s harder to print with but my experience was it’s easier to get a good print with ABS- it’s just harder to get a half-assed one, it tends to either work great or fail whereas PLA has varying degrees of failure that you might tolerate. As long as you have good print conditions anyway, heated bed and warm space helps loads

PETG is pretty much the best of both worlds as far as I’m concerned, apart from price.

AlexSimonFull MemberPosted 6 years agoPLA and PETG are probably all you need imo – unless you need reaaaally specific properties.

ABS seems a bit redundant now to be honest. Vapour smoothing is about it’s only unique trait.I had a couple of uses for wood-filled filament, but it always clogged my 0.4mm nozzle. Keep meaning to get a 0.6mm and try again. It looked great for map-based stuff that I’ve done quite a bit of work with.

For cheap PETG, I used Real Filament from Amazon for my CNC parts. Seems fine after getting bed adhesion sorted. Other than that, I’ve mostly used PLA from Das Filament with the MasterSpool system or recycled PLA from Filamentive (but you kind of have to wait for a 40% off code that comes around every few weeks.

Hardly ever any problems with even cheap PLA though, so the only reason I’ve spent more is if I’ve wanted a specific colour (some do Pantone references).

WorldClassAccidentFree MemberPosted 6 years agoPETG for me too. £20 per kilo from Real Filaments. Some of the non-coloured stuff is meant to be food safe if that is relevant.

PLA is easy as long as you are just making toy models and don’t need any strength / UV resistance.

I have just finished a real of flex-translucent stuff from RS Componants and it is the devils material. Always the will it / won’t stick to the bed. Printing at 25% speed, lots of mid-print delaminations….

stumpy01Full MemberPosted 6 years agoDepending on your requirements, don’t rule out PLA.

There are better ‘engineering’ options out there, but for many applications it is fine.I made a shim for our rotary clothes drier with PLA & it has been in use since around March time, pushed into a rusty tube & left there, out in the rain & this summer’s heat – it is fine.

I am not sure how it would have had fared if it was more exposed to direct sunlight, but almost everything I have made so far in PLA has held up well.

You definitely need to consider strength while designing & it’s not as easy as taking a part that might have been machined from aluminium previously & copying it.I have used 3DQF & Hobbyking filament so far. I do have a sample of PETG, but while my printer is working well, I am loath to stick something ‘unknown’ into it. If I really had a pressing need for PETG parts, I would consider buying one of those Ender 3’s and running it solely on that material (so long as the build volume was enough).

For bed adhesion, I recently tried a watered down PVA glue mix – 2:1 water:glue and used a 3-D printed spreader to get a thin layer on the bed. It kept beading up, which cheesed me off a bit as I’d designed and 3-D printed the spreader myself, but it seemed to be a non-starter. As a final act of desperation, I used my finger to smear the mix over the glass bed. It was loads better but not perfect. The next day I came back to it & it was smooth as glass & virtually invisible; I guess it found it’s level as it dried. The first layer ended up looking super-smooth & glass like – almost as good as printing directly onto the bed.

It was a bit of a pain in all honesty, & if I was going to continue using this, I would buy a couple of sheets of glass, so I could rotate them – removing the parts from the bed lifted the glue film, so it needs to be re-applied every time.

I might try adding something to the mix next time to get it to wet-out better (a surfactant I think, like a teeny drop of washing up liquid).NorthwindFull MemberPosted 6 years agoI fannied around with pva, then I bought a big pack of purple glue sticks and just switched to that- it’s obnoxiously good for adhesion, I’ve had quite a lot of trouble removing some larger parts.

Just ordered myself a flexbed for the anet, it’s got a buildtak copy on it so hopefully might be enough by itself

stumpy01Full MemberPosted 6 years agoI fannied around with pva, then I bought a big pack of purple glue sticks and just switched to that- it’s obnoxiously good for adhesion, I’ve had quite a lot of trouble removing some larger parts.

Just ordered myself a flexbed for the anet, it’s got a buildtak copy on it so hopefully might be enough by itself

Yeah, up until now I have used Pritt Stick which works fine. But, it doesn’t leave a great surface finish on the bottom of the part IME.

We use 3DLac at work on our Ultimaker3 & the surface finish is amazing – mirror-like with great adhesion. But, at over £14 a can I can’t really justify it for home tinkering.I keep meaning to try some watered down PVA in a small sprayer, but imagine with that I’ll have to rinse the sprayer nozzle every time I use it.

We also use Buildtak at work, but have ruined a couple of sheets with too much adhesion; literally couldn’t separate the part from the buildtak.

That was a colleague who was fiddling around with polycarbonate, so maybe it’s not such an issue with PLA/PETG etc. although I have heard PETG direct onto glass is a definite no-no.If I get round to it, I’ll take some pics later of surface finish using pritt stick compared to my watered down PVA attempt.

The topic ‘Cheap 3d printer kits – Experiences?’ is closed to new replies.

A friend of mine used his Printrbot to update his vintage bike, he designed new parts like a controller mount in

A friend of mine used his Printrbot to update his vintage bike, he designed new parts like a controller mount in