Home › Forums › Chat Forum › Cheap 3d printer kits – Experiences?

- This topic has 690 replies, 36 voices, and was last updated 4 years ago by zilog6128.

-

Cheap 3d printer kits – Experiences?

-

NorthwindFull MemberPosted 7 years ago

Cougar – Moderator

Sounds expensive. Where are you sourcing Lego from at ten quid a kilo?How much it weighs not how much it costs! But I think you know that 😆

It does depend a lot on how dense you print- a lot of what I do is very solid, for strength and crush resistance. But a cosplay piece usually isn’t going to be like that, you’d want it to be durable but not bombproof. So you can set the infill low and have solid outsides but print the inside in a honeycomb or similiar, to save weight (and therefore plastic). Not to mention time.

TINAS is spot on, time is a big deal, for actual industrial printing or for anyone doing it full time it’s a real cost (for me, it’s not, my printer doesn’t run constantly so it’s an unspent resource). And that’s where having your printer really dialed and reliable comes into its own, too- I can put on a 10 hour job and be pretty confident that if it’s printing OK after 10 minutes, it’ll produce something decent. But if it’s less reliable, there’s a pretty good chance you come back and you’ve printed a massive blob- wasted a load of filament but also time and maybe created yourself printer issues too.

(they say never leave it unattended but I doubt anyone actually follows that advice; I have an old smartphone running as a webcam so I can keep an eye on mine for safety but I very rarely run it overnight (and the room I have it in is pretty fire safe anyway) It’s a low risk but, high enough to think about

And you’ve got to consider mean times to failure too- being able to run for an hour reliably is fine for a lot of the parts I print but if you’ve got a big job to do, you need a different level of reliability

AlexSimonFull MemberPosted 7 years agoGot mine working my fiddling with some wires (Creality support wasn’t quite as bad as I expected).

Printed a strain relief for one of the wires which people recommend and then went onto a 3D Benchy[/url] and calibration cube.

All came out much better than I expected:

Very pleased. Time to start printing some of my own creations!

CougarFull MemberPosted 7 years agoHow much it weighs not how much it costs! But I think you know that

I didn’t, I just misread what he was saying.

you can set the infill low and have solid outsides but print the inside in a honeycomb or similiar, to save weight (and therefore plastic). Not to mention time.

Ah, cunning. I hadn’t thought of that, ta.

Presumably for bigger pieces you can make them in modules, like quarters or something, and stitch together? (And that’s probably preferable because of possible failure.) Like, if I wanted to make a sub-machine gun prop, I could do it in quarters or something.

NorthwindFull MemberPosted 7 years agoThat’s a pretty good benchy! Here’s my first:

@Cougar- yep, also means you can make things bigger than your printer too. Design and slicer software can cut up parts pretty easily too so you can make your own splits. And if you print in ABS, you can stick it all together with just a little acetone.

timnoyceFree MemberPosted 7 years agoAlexSimon, I just googled the CR-10 and it looks immense. I’ve got access to an Objet30 and now the Markforged, the resolution is excellent but the build size is limited to around 300x120x150 on both. The CR-10 looks amazing for the money. Totally interested in something like that for home use now!

Looking forward to seeing some more of your prints 😀

AlexSimonFull MemberPosted 7 years agoReally pleased with how everything is coming out.

That heater cartridge failed again today, but pliers sorted it and they are sending me a new hot end (who knows how long it’ll take to arrive). I ordered a cheap cartridge of ebay in the meantime, but I think I’ll just make do (don’t trust my soldering or want to mess with it too much).Anyway – printed a few bits and bobs – all look great. Vase mode is particularly impressive.

This is the latest.

It’s the springy turtle off the Thingiverse home page.

Need some more matt PLA and some different colours. Getting bored of orange and white!

AlexSimonFull MemberPosted 7 years agoIn the meantime, we’ve been learning Fusion 360 and have been designing our own things.

Really enjoying it, although it’s always difficult when you start a project and think “ok – how do I start this shape then”.

For example, I wouldn’t know where to start with that turtle shell.MilkieFree MemberPosted 7 years agoDo any of you print while you are out the house? I have a 24 hour print to do (50m of 3mm filament) but I’m not too sure about printing when I’m out the house, it hasn’t screwed up yet while printing.. I do use OctoPi withe PiCam to keep an eye on the prints when I’m around the house.

The best bit of advice I was given when learning CAD was there is no wrong or right way of drawing, but there maybe a quicker way.

AlexSimonFull MemberPosted 7 years agoDo any of you print while you are out the house?

If I had a professional machine I would probably do it, but not with these Chinese kits. Same as charging Chinese batteries for lights 🙂

And that’s just my shed. Even less likely in the house.

AlexSimonFull MemberPosted 7 years agoWell after wondering what we were going to print, I have to say that the printer has been running about 8 hours a day whenever we’re at home!

Completely sparked my boys’ imagination and they are loving Fusion 360 (as am I).

Currently printing loads of bits to make a Nintendo Switch car mount which my eldest designed.

I’ve been sticking to mostly graphical pieces like these two signs for local clubs I’m involved with.

The green and white one involved a nerve-wracking filament change at the right layer!

stumpy01Full MemberPosted 7 years agoWow! Missed your turtle update….looks great, as do those two signs!

What is going wrong with the heater cartridge, then? Failing to heat, I guess?

Where do you source a replacement from? Are they standard or do you need the cartridge from the printer manufacturer?AlexSimonFull MemberPosted 7 years agoIt’s just a poor crimp on the connection I think. I can get it working by squeezing with pliers, but it fails every-so-often.

I have a replacement heater here (cost £1.99and are a generic item), but I don’t fancy soldering and messing. The whole hot end assembly is £24.

Gearbest have been worse than useless. Creality were helpful with advice, but said I had to go through Gearbest.I’ll probably suck it up and buy the £24 option.

SammyCFree MemberPosted 7 years agoLooks really cool, but I don’t think my budget and space will stretch to the CR10. What are peoples thoughts experiences with an Anet A8?

stumpy01Full MemberPosted 7 years agoAlexSimon, ta for the explanation.

SammyC – Member

What are peoples thoughts experiences with an Anet A8?Plenty of reviews on YouTube. It seems to be quite a capable machine.

AlexSimonFull MemberPosted 7 years agoThe A8 is all about the mods. Out of the box it’s average – once you print your own modifications and tweak it, it can be great.

If I was buying now, I’d be tempted by the Creality Ender-2 (also rebranded HICTOP). Currently about £135 with codes.

Small print volume, but many shared parts with the CR-10.AlexSimonFull MemberPosted 7 years agoI haven’t actually printed anything beyond that print volume either.

I do have something in the works, but to be honest I could do it in sections without too much bother.On the CR-10 forums it seems dominated by cosplay costume makers and modellers who like to print massive anime figures and fill/paint them.

Apart from the fact that obviously everyone would like an IronMan suit, I don’t seem to be it’s target market. Mainly because I’m too impatient to wait days for the big prints to finish 🙂

(Basically I should have bought the Ender-2 🙂 )

CougarFull MemberPosted 7 years agoApart from the fact that obviously everyone would like an IronMan suit,

Mate of mine’s making one of those. Using foam rather than plastic though.

SammyCFree MemberPosted 7 years agoI think that’s what holds me back is the what would I use it for question. But I could use it for work in many situations and my boys would love playing with it.

drewdFull MemberPosted 7 years agoI have been following this thread with interest and that Ender 2 is really tempting.

I also have no idea what I would make with it, but still want one.

AlexSimonFull MemberPosted 7 years agoI was worried about what to print too (as you can read earlier in the thread), but now that it’s here, ideas come from everywhere.

But then I am a designer by trade.stumpy01Full MemberPosted 7 years agoAlexSimon – Member

If I was buying now, I’d be tempted by the Creality Ender-2 (also rebranded HICTOP). Currently about £135 with codes.

Small print volume, but many shared parts with the CR-10.I’ve had a look at the Ender-2 and it does seem to get good reviews.

I can’t help but think that the cantilever nature of the design won’t give as good results – particularly as things start to wear.

GrahamSFull MemberPosted 7 years agoThis might be of interest. Adam Savage with one of those 3D-printed mega-scale Curta

AlexSimonFull MemberPosted 7 years agoAmazing finish on that. I wonder if it’s just an amazing printer, or if it’s post-processed.

MilkieFree MemberPosted 7 years agoUnfortunately this isn’t an amazing post with photo’s of what I’ve printed. 😐

I have found a super cheap 3D printer, under £100 and print volume is 220x220x240mm 😯

EDIT:

I did design a Evil Wreckoning Clip Holder. This needs an update as over time it becomes loose.

I designed a replacement top cup holder ring for the Sakura cup holder, it now holds a proper cup of coffee (Costa/Starbucks), this is fitted in my car as it only came with one cup holder.AlexSimonFull MemberPosted 7 years agoThe Anet A8 is very well known.

I put some comments in the end of that thread.Basically, only buy it if you have plenty of time and patience, but once modded it can be safe and high quality.

If you value your time more than your cash – buy something better.

joshvegasFree MemberPosted 7 years agoproper cup of coffee (Costa/Starbucks),

Go away and think about what you’ve done.

petefromearthFull MemberPosted 7 years agoI looked briefly into getting a 3d printer at home, but talked myself out of it as I really don’t have much to make or any time to play with it.

Instead I’ve used these guys a few times and find them to be very good.

https://www.3dprint-uk.co.ukYou send them an STL file of all the parts you want and they arrive about 2 weeks later.

They only use SLS (nylon) which is the process used by most engineering/design companies for working prototypes. The parts are very durable and stable over time.

I used to work for Dyson and SLS is used for almost everything, the machines cost big money.

The price is just set by the external dimensions, so you can position parts in such a way that gets best value for money. Anything hollow can be filled with bits which are effectivity free.

AlexSimonFull MemberPosted 7 years agoAs clones of the Creality CR-10 go, this looks pretty good!

£259 with the code from the video seems good value.

AlexSimonFull MemberPosted 7 years agoI’ve just started my next big project.

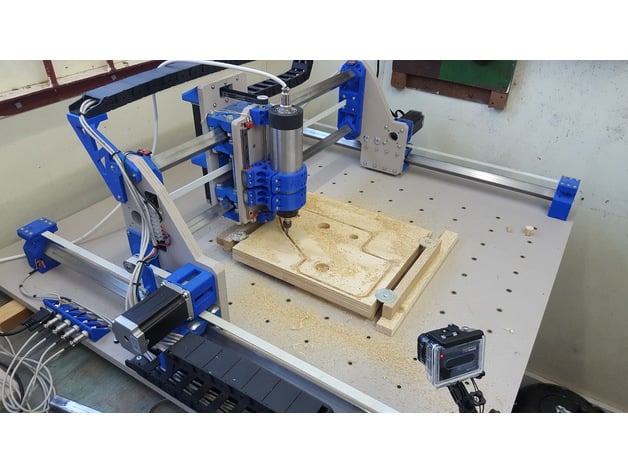

A CNC Router made from a lot of 3d printed parts.https://www.thingiverse.com/thing:1750276

At first I thought I could build one for about £300, but the models that come in at this price (MPCNC and a couple of others) look a little flimsy for purely routing ply and aluminium, so I’ve gone for this one instead.

My Bill of Materials currently sits at £440 including PLA and everything. Slightly concerned that it’s an awful lot of money to spend on something that also requires a lot of time and skill to get working, but I’m sure my son (and YouTube) will come to the rescue!

Most of the bits are currently on their way on a slow boat from China.

Hoping to do the bulk of the work over the Christmas break.Time to get printing!

AlexSimonFull MemberPosted 7 years agoDecided to print the blue bits in the image above in PETG so that it’s heat resistant and stronger, but having an absolute mare trying to get it to stay stuck to the bed during the long (12+ hour prints).

Glass on 70-degree bed and slow printing = Nope

Glass on 80-degree bed and slow printing = Nope

Pritt stick on 80-degree bed and slow printing = Nope

Hairspray stick on 80-degree bed and slow printing = Nope

Blue masking tape on 80-degree bed and slow printing = Best so far, but it’s still starting to warp at 4 hours 🙁I’ve heard PETG doesn’t like to be as squashed into the bed as much as PLA, but my attempts to do that resulted in hardly any sticking at all (even the brim came off before completing).

Any tips?

MilkieFree MemberPosted 7 years agoI’d suggest giving ColorFabb XT a go. I bought some, not knowing it was similar to PETG, until yesterday when I went to re-order another roll. I find it sticks to the bed just fine, it’s actually hard to get off the blue tape, I don’t use a heated bed. Recently printed a part that was 250×80 by 60mm high and it didn’t warp or lift.

I do print the first layer at 50% speed and about 10°C hotter than the rest of the print and no cooling until about layer 3, it also in an enclosure. Have a look at Simplify 3D, it is worth the cost, as has a lot of cool features such as custom settings for first layer and loads more things.

allthepiesFree MemberPosted 7 years agoPETG can also take chunks out of your glass bed when you remove the finished item 😯

AlexSimonFull MemberPosted 7 years agoallthepies – Member

PETG can also take chunks out of your glass bed when you remove the finished item That would at least mean that I’d got to the end of a print! 🙂

Milkie – Member

I’d suggest giving ColorFabb XT a go. I bought some, not knowing it was similar to PETG, until yesterday when I went to re-order another roll. I find it sticks to the bed just fine, it’s actually hard to get off the blue tape, I don’t use a heated bed. Recently printed a part that was 250×80 by 60mm high and it didn’t warp or lift.Interesting. I can’t really afford ColorFabb XT (need 2.5kg for this project), but then buy cheap buy twice!

MilkieFree MemberPosted 7 years agoThat is exactly what I have found. I don’t buy cheap stuff anymore, gone through many reels of cheap stuff and just ended up chasing the settings, printing more than once and ruining a nozzle. 2.5Kg though 😯 How big is the part?

AlexSimonFull MemberPosted 7 years agoAll those blue bits on the image above (the CNC router). It requires 50% infill.

nickjbFree MemberPosted 7 years agoI understand the act of making it is fun in itself but in this case wouldn’t you be better off buying something? For example this is almost exactly the same as your bill of materials: https://www.ebay.co.uk/itm/300W-3040-New-3-Axis-CNC-Router-Engraver-3D-Engraving-Drilling-Milling-Machine/263151299677 but all aluminium and already working.

That’s pretty much the machine I started on. Very sturdy construction and worked well until I sold it on for about half what I paid for it and bought/built a much bigger one.

stumpy01Full MemberPosted 7 years agoNo help with the question about printing with PETG.

No help with anything else really, as I don’t yet have a 3-D printer.

But, I’ve just been told that we are going to get a bonus this small Christmas bonus this year, because things are finally looking up in the industry I work in & the company is making good progress.

Anyway – I am planning on splitting it 50/50 with my Wife, but this will still hopefully leave me with enough to get a budget 3-D printer.Excited already & I’m still not really sure if a) I’ll get enough of a bonus to afford it, or b) what printer I would be able to get.

I like the idea of the CR-10, but not sure I need that much build volume.

Tevo Tarantula looks like a good performing printer for the price.

But, now the Anycubic i3 mega has popped onto my radar & also looks like a good bet!I’ll get Christmas out of the way first & then worry about it!!

AlexSimon, good luck with the 3-D printed CNC router and getting your parts printed!

stumpy01Full MemberPosted 7 years agoBlimey – doing a quick search….has anyone bought anything from lightinthebox.com?

They’ve got the:

– Tevo Tarantula for £117

– Tevo Tornado (rip-off CR10) for £234

– Anycubic i3 Mega for £220!!Even the Tevo Tarantula with dual extruders is only £173…..

The topic ‘Cheap 3d printer kits – Experiences?’ is closed to new replies.