- Tested: “The Gravel Wheel”

- From: Sharp Precision Wheels

- Price: £640

We get a good few wheels through the doors of GritCX and Singletrack. Whether it be stock wheelsets on test bikes, or models that are sold aftermarket, ready to upgrade an off-the-shelf bike. The vast majority of those wheels are factory built. There’s a lot to be said for that, as well. It’s been a long time since I’ve come across a truly badly built wheel on a bike.

There is still room in the market for custom built wheels though. The benefits of mixing and matching rim, hub and spokes to meet specific requirements and/or budget shouldn’t be underestimated. It might sound a little old fashioned, but it’s also nice to know who built your wheels; threaded each spoke, tensioned it up, checked and double checked the build before shipping.

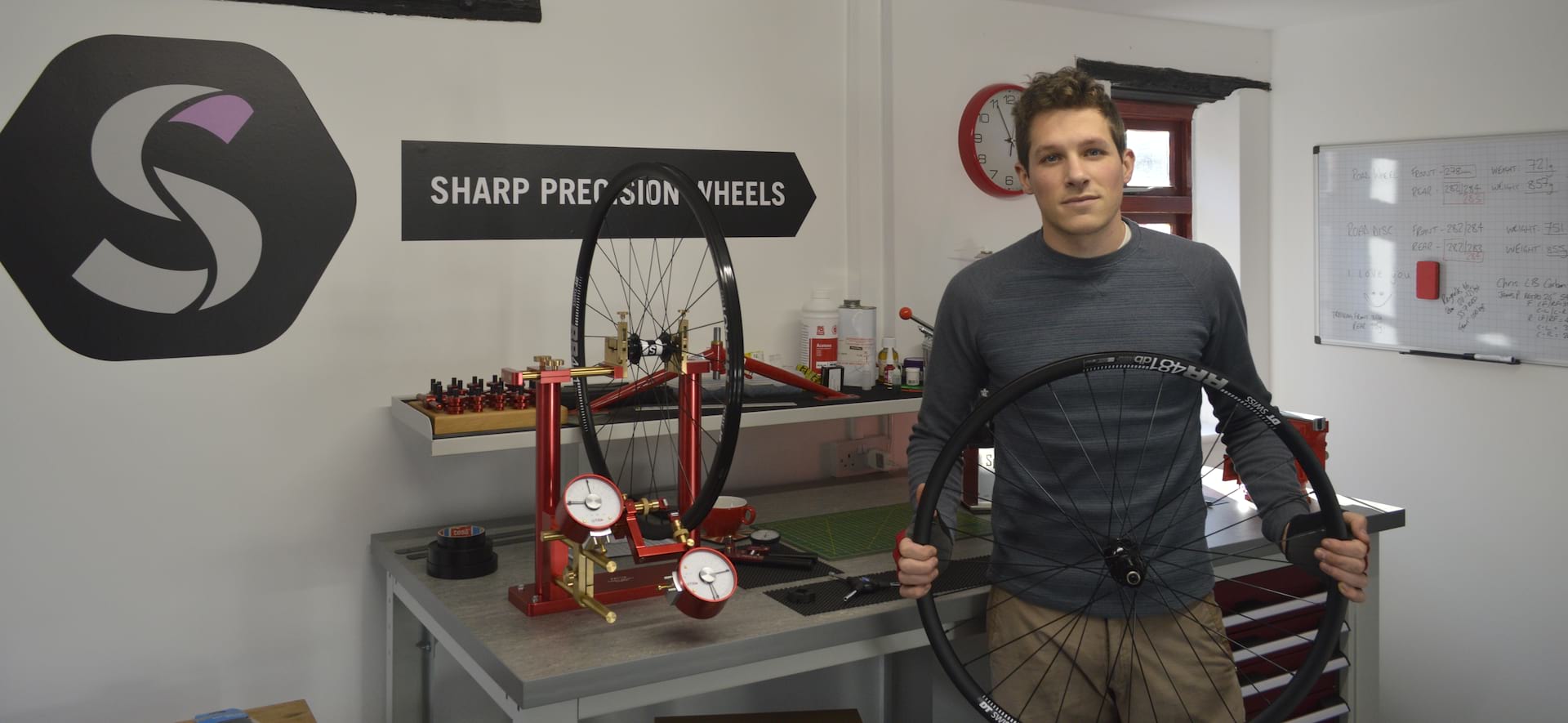

Sharp Precision Wheels

We received an email from Ben Sharp at Sharp Precision Wheels a couple of weeks ago. He was keen to send us a wheelset to test, but rather than point us in the direction of a particular build, he encouraged us to take a look at his website and think about what we’d like the wheels to do. Sharp offers a number of “stock builds” which he thinks represents the best combination of components for a given purpose and price. While most of his offerings are road-based, he offers a couple of gravel/’cross options.

After a chat about what we’d do with the wheels (everything from tarmac to some inappropriate “gravel” trails and bikepacking), Sharp recommended his “The Gravel Wheel” package. This consists of DT Swiss RR481 rims with a 22mm internal width, Sapim CX ray spokes (28 front and rear) and DT Swiss 350 hubs. We’ve had good experiences with similar builds and rate the DT Swiss hubs in particular, so we are optimistic that the wheels will tick the boxes out on the trail. Interestingly, Sharp has chosen to use alloy nipples for the build. This would normally lead to a raised eyebrow from us. We’d always usually prefer the added reliability of brass nipples, despite the marginal extra weight. Sharp makes a good case for his choice though – check out our interview with him below.

The wheels are available in 650b, or the 700c that we chose. At the larger size, Sharp claims that the wheelset weighs 1695g. Ours came in just over 1700g with tape and valves fitted, so that sounds bang on. It’s not a crazy-light build, but going much under tends to need either a lot of cash throwing at the situation or a compromise in strength. As it is, The Gravel Wheel costs £640 – certainly not cheap, but we think it sounds like a reasonable price given the build and the time that Ben evidentially spends.

There were some nice touches in the wheel box that arrived at GritCX Towers. The wheelset comes with a “birth certificate”, a little pot of freehub grease, and lockrings for the Centerlock brakes.

The proof will obviously be in the riding, but if passion is an indicator of performance, there shouldn’t be much to worry about.

Ben Sharp

One thing that was evident in our email discussions was Ben’s passion for what he does. We were interested to find out a little more about him and what he does.

How did you get into wheel-building?

“I originally trained as an archaeologist, and after years of working both in the UK and Middle East in Qatar, Iraq, Jordan and Abu Dhabi I decided to hang up my trowel and immerse myself in the cycle trade.

“Keen to learn a creative skill, I went to work for the largest hand builder in the UK for 5 years, ultimately becoming workshop manager. Such intensive training enabled me to become a master wheel builder, and it is the depth of experienced gained by using such a huge variety of components for such a wide variety of riders which really sets me apart from a lot of other builders. Having focussed purely on wheels, without the other distractions of a typical bike shop, meant that I knew exactly what I wanted to achieve when starting my own business.”

Why did you start Sharp Precision Wheels?

“My knowledge and experience as a wheel builder is invaluable to me in recommending the best combinations of parts to match a specific riders requirements, but starting Sharp Precision Wheels was a chance for me to combine that with a meticulous attention to detail and put all the finishing touches into every pair of wheels I produce to make that purchase as personal and special as it should be for the customer.”

What do you think sets you apart from other wheelbuilders?

“Every pair of wheels comes with a birth certificate detailing its finished tolerances, hand stamped tags, full after-care instructions, some grease for the freehub body and centrelock splines, and a decent box which is tough enough to re-use if you want to send wheels back for service. I really want people to be proud to have purchased a pair of wheels from me, and I want to do everything I can to look after them long-term. All the finishing touches are a reminder to the rider that my skill and effort was focussed purely on them, and I hope the finished package is truly unique.

“I love climbing on a bike and (when I’m not falling down holes and injuring myself running) you’ll likely find me out riding around all the big climbs Sussex has to offer: Ditchling Beacon, Devils Dyke, Steyning Bostal, Bury Hill. For me, riding in the French Alps has been heaven, and my focus for the last few years. It’s an intoxicating environment which makes it so easy to get on the bike and ride, either on well tarmacked roads or lesser known gravel balconies. I’ve become a serial participant in the Marmotte sportive, having finished 115th in 2014, and I don’t think I’m going to be able to kick the habit any time soon. I’m also a multiple Half and Full Ironman triathlon finisher as, but it’s been a while since I sat on a TT bike!”

Why go for a custom build?

“What we get up to on our bikes has never been more varied, and so too are our priorities on the bike. In my opinion, this makes a hand built wheel more relevant than it has ever been. It is the best way to truly address the needs of the individual. Gravel cycling and CX popularity has soared and I think it is largely due to a desire for “fun” on the bike again. We want to enjoy cycling again, focus less on the numbers, and get away from the stress of the traffic. Teams like EF Education First in the pro peloton are taking part in loads of off road-events this season and putting more emphasis on fun and immersing people more in the world of cycling. For a lot of people a bespoke bike can form part of that love and enjoyment of the cycling world and I think that a hand built wheel can provide a little of that immersion/experience/kudos, but at a much more accessible price for the majority of riders.

“Aesthetics are important. Cycling isn’t just a form of transport for many people: it is deeply personal, and it can be an indulgence. A chance to have things exactly as you like them, and be creative. If you want bright pink hubs, red nipples or a more stealthy looking wheel, then talking to a custom wheel builder will help you get closer to your personal idea of aesthetic perfection. It’s also an involving and rewarding experience. In buying a custom build you are engaging in the process and supporting a small local business. Every pair of wheels I build is the culmination of about 8-10 hours labour, personally focussed on doing the best job possible for that individual. From the first turn of the spoke key to the hand stamped tags and birth certificate, you are paying for attention to detail and a personal touch that you don’t seem get very often these days.

“Perhaps above all, it is the consultation process and ability to tailor the components of a wheel to an individual that makes a custom wheel so compelling. Carrying luggage and want something tough, want a more compliant wheel, want something which is super stiff and transfers power immediately? No problem: we can talk about exactly what you get up to on your bike, and what you feel are the most important qualities in a wheel, and come up with a combination of hub, rim and spokes to fulfil those requirements. Not only is buying a custom wheel a chance to make sure you buy something which is right for you, but equally it should steer you away from products which you might think are great but wouldn’t suit your day to day requirements well in the real world. Sure, it takes a little longer to commission a custom build, but it means you can get something which is truly fit for your individual purpose.”

Why do you think The Gravel Wheel that you’ve sent is the one for us?

“The Gravel Wheel that I’ve sent you is designed to be an all-round gravel wheel which delivers high performance across the board, rather than just focussing on specific trait. It’s an upgrade for people who spent £1000-2500 on their bike and want a quality conscious wheel which is reliable and as wide as possible. To that end, it isn’t the lightest wheel at this price point, but it will “feel” light to ride. Most of the weight is concentrated in supplying a quality hub for the build: the DT Swiss 350 Centrelock. It’s easily convertible between axle standards, and its design has been proven over many years to deliver good resistance to the elements and a very long bearing life. It doesn’t have the fastest engagement on the market, with an 18-tooth ratchet as standard, but it is phenomenally reliable and has a very long service interval as a result of that. It can easily be upgraded to 36 or 54 tooth ratchets and is easy to field service with no tools at all. Simply it’s a great hub which is easy to live with, with great flange placement for building a stable wheel.

“Laced with 28 spokes in a 2 cross pattern front and rear with Sapim CX Rays at high tension, it builds a very responsive wheel. The CX Ray does an epic job at high tension: It absorbs buzz and impact well, while at the same time transferring torque efficiently. Being so light, it helps build a wheel which accelerates well and doesn’t feel heavy.

“The DT Swiss RR481 DB rims are super wide at 22mm internal, so you can run big tyres tubeless at really low pressures, but also they will take a 28-32c road tyre at higher pressures if you need to hit the tarmac for a while. It’s available in 650c or 700c to suit your bike and riding.

“I use an alloy nipple for the build to keep rotational weight down and improve the responsiveness of the wheel, but it has a Hex head with an ABS plastic locking insert. It’s made by Alpina in Italy and is extremely resistant to failure and corrosion, and I use a Dynax anti-corrosion wax inside the rims to further boost its resistance to the elements.

“I think it’s a great combination of parts which strikes a balance of quality, strength, responsiveness, comfort, and ease of service. It can easily be revised for riders who are super light, or equally for those carrying frame bags and panniers who want a little extra strength on longer adventures.

“It’s hand built by me, in my Sussex workshop, and no effort has been spared to bring the components to their maximum achievable tolerances.”