Revel, the Colorado brand behind Revel Bikes and Wheels, has been experimenting with 3D printing in order to make a FusionFiber bike. This is a type of thermoplastic, and using it can avoid the epoxies needed to use carbon fibre layups. In the longer term, it’s hoped that this might make it possible to recycle frames and components made from this material. For now, it’s an experiment in what’s possible (and an opportunity for some publicity). Read on for the full PR, plus Singletrack Members get to read some extra questions that we put to Revel.

Here’s the PR:

Revel’s’ enthusiasm for innovation doesn’t stop at the frames, and in 2020 they introduced the world to the next generation of carbon wheels with the RW30 FusionFibertm wheels. Embracing the latest aerospace engineering practices, Revel launched the world’s first fully recyclable and environmentally responsible method of producing a carbon wheelset using a unique thermoplastic engineering process developed by CSS Composites. The FusionFiber RW30 can be produced without the need for harmful, brittle epoxy, and the result is a recyclable, high-performance composite rim that is significantly more durable, lighter, and overall a better riding wheel than other carbon wheels on the market.

Implementing FusionFiber for components manufacturing redefines what is possible when you look outside of the industry standards for production, and that is just what Revel is doing with their newest passion project – The Rodeo.

Latest Singletrack Merch

Buying and wearing our sustainable merch is another great way to support Singletrack

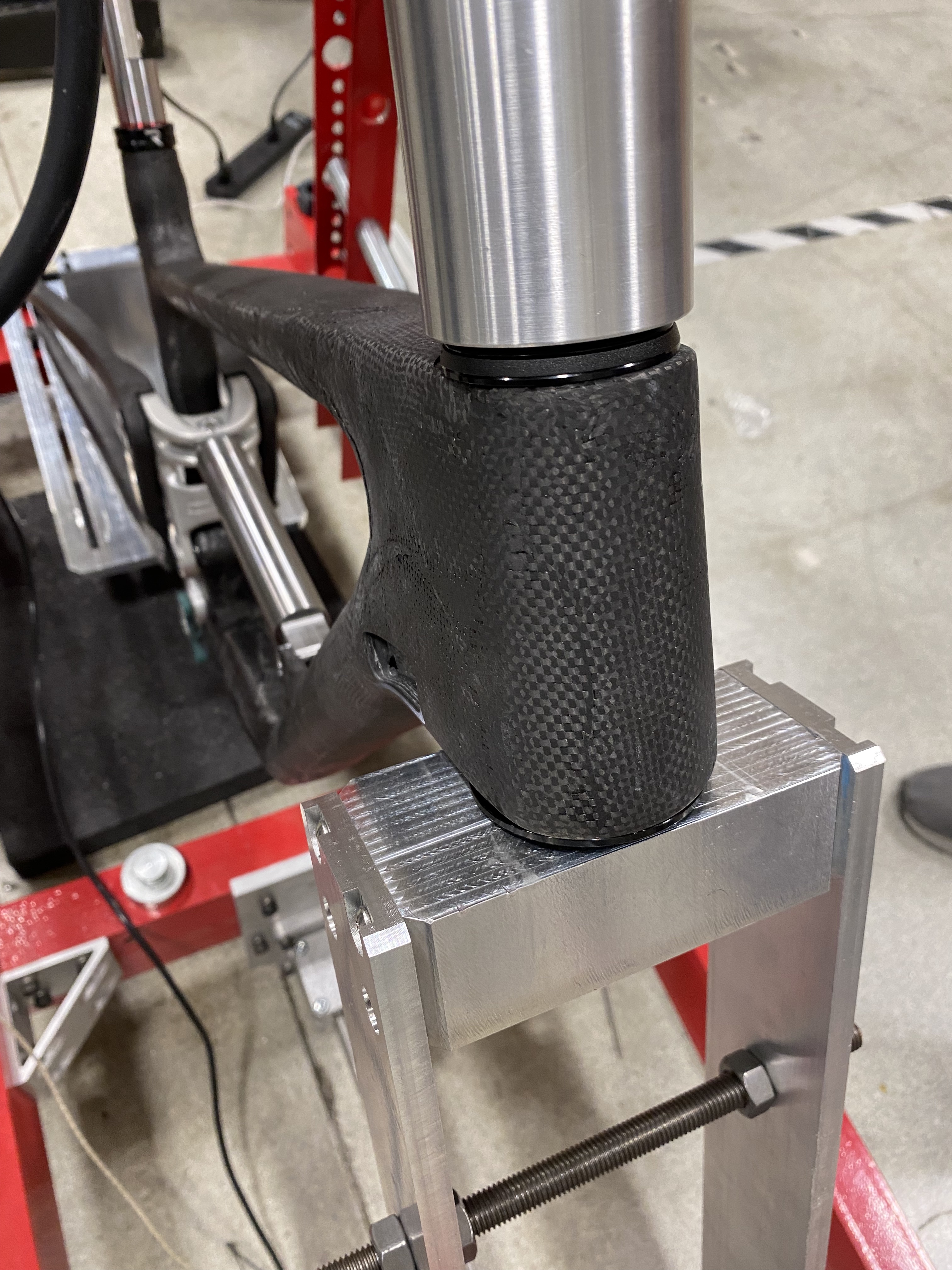

What started as a conversation between Adam Miller (Revel Bikes) and Chris Canfield (Inventor of CBF) in a coffee shop while waiting out a rain spell before a ride soon became tangible as they explored options to create a fully functional carbon downhill bike without the typical methods of manufacturing. Ignited with fire to bring something new to the cycling industry, Revel was introduced to Arevo Inc. – Pioneers in the additive manufacturing space and has already brought their own fully functional 3D printed bike to market. When the opportunity presented itself to begin the development of Revel’s own 3D-printed frame – they saddled up and got to work on a prototype Downhill frame. Jordan Haffener (Revel Bikes Senior Engineer) worked closely with Arevo at their facility in Silicon Valley to develop dozens of prototypes before landing on a design that passed muster. Designing a Downhill bike is one of the most ambitious undertakings for any brand because they experience abuse unlike any other, from massive drops, high-speed G-outs, and lateral stress from aggressive cornering; they demand durability and reliability to withstand seasons of riding.

The Rodeo is just a concept for now. Still, it serves as an example of conviction, innovation, and what is possible with current technology and what could be a reality in the future. It’s hard not to get excited about the prospect of a 3D-printed carbon bike made here in the United States, and the ramifications could mean incredibly improved prototyping and development processes for bike brands, safer conditions in production facilities, significant environmental benefits, and greater customization for the rider at better costs. Revel believes that this method of frame production could be the future for carbon bicycle manufacturing, and the Rodeo is proof that this is a real possibility that could become more of a reality for practical, reasonable-cost full suspension mountain bikes with continued technological advancements. A 3D-printed carbon mountain bike is doable, and with further innovation, there is even the potential for this thermoplastic composite material to be fully recyclable.

For now, this technology is too new to bring this bike to the masses. The entire process is incredibly time and energy-consuming, not to mention prohibitively expensive, and it is not realistic to bring The Rodeo to production at this time. But as innovations in additive manufacturing and thermoplastic technology continue, the possibilities of mountain bikes like this coming to market become very real.

Why a DH Bike?

Starting with a DH bike will allow Revel to trickle down what they learn during the R&D process to make the entire process more efficient for future large-scale production of other models, and they hope that starting with such a daunting task will encourage other brands in the industry to explore the potential that this method has to offer.

A Downhill bike needs to be overbuilt – the construction can have no compromises, but weight is also not a huge factor to consider. Although having a lightweight bike will aid in maneuverability, a fine line must be navigated between weight and structural integrity, which kept Jordan and the design team at Arevo hard at work while developing a bike that Revel felt comfortable putting to the test.

A World’s First

3D printing is being used everywhere. Most recently, there has been a huge surge of companies taking the additive manufacturing route for various components and even tube junctions on frames. Revel sought out Arevo and their technology because they have developed a method of 3D printing structurally sound composite products for the intended use. Revel jumped at the chance to see their dream materialize and push the limits of innovation. The Rodeo is the world’s first 3D-printed, thermoplastic carbon fiber mountain bike and the world’s first carbon CBFtm suspension downhill bike. Although just a concept, the Rodeo is proving what is possible.

Why The Rodeo?

Revel Bikes is based in Carbondale, Colorado. During the summer months, Carbondale hosts a weekly rodeo event every Thursday, and the Revel crew is often found hanging out at the rodeo after a post-workday bike ride. They even have an official company party at the rodeo every summer, and a downhill bike made in America just made sense to be named the Rodeo.

If you’re still intrigued after that, Members can read on for a few questions that we had…

Have the prototypes been recycled into Revel wheels?!

They have not – we’re keeping all the prototypes for wall art because they are awesome and represent a crazy amount of hard work from our team! The prototypes have the potential to be recycled since the thermoplastic material is extremely similar to what our wheels are made out of, but we have not taken that step. It will require a bit more of a process to recycle than our wheels but shows significantly more promise than standard thermoset carbon frame recycling options that are out there currently. This is still in the early concept phase when it comes to recyclability, but we believe it can be done, and done economically in the future!

What needs to happen/what technology do we need for a bike like this to be fully recyclable?

The process needs to become cost-effective. For now, the technology exists, but it is too slow and expensive to be financially feasible. Balancing the economic and environmental benefits will be the ticket!

From the pictures it looks like it’s been built in two halves? What method are you using to join the two halves together?

This is where things get proprietary! Our friends at Arevo who helped engineer and print the Rodeo developed some pretty fascinating technology here.

Approximately how many hours does it currently take to print one frame like this?

A bit over 40 hours right now.

Does it meet DH testing standards, or is it still to be tested?

We got the bike to pass normal ISO standards, but further development is needed to pass the standards that a DH bike would require. We have more to learn and more to innovate on to get to this point, but we just wanted to show off something pretty cool for now!

What does the frame weigh, what size is the one you’ve made?

It is a little on the heavy side still – it is a work in progress! Our most recent prototype weighs 10.5 pounds. Still a bit on the heavy side, but again, this is a work-in project that we wanted to show off. To bring this product to market, we would want the weight to be a little bit lower and the price to be reasonable. We’re not quite there yet and that’s why this is just a concept bike for now!

Who got to ride it first – Adam or Chris?!

Oh, we fought over this one! Even though Chris beat me in the last Snowmass downhill race by 7 seconds, I still got to pedal this bike first since Chris was busy snowboarding in Utah hahaha. We’ve still just done limited ride testing on this bike since it’s not quite ready for the full-on downhill craziness yet.