This month for Back From The Dead we’ve got plenty to get through! An update on how Jack’s progressing with his apprenticeship; a couple of tools I’ve made (and one Jack’s made!); a few new cool tools in my box that I like and dislike ; then finally a tale about playing a Cycling Community Chest card and ending up winning second place in a beautiful hammer contest!

We’ll start off with young Jack and a bit of an update on his apprenticeship.

Since I last spoke about Jack he’s had his first few meetings with Adam his assessor from Activate Learning to properly run through his course and give him a decent overview of what he needs to know before examination for each of the grades of his Cytech course. In what I’m sure was pretty assuring news for a nervous Jack, he’s already at least partially acquainted with just about every skill required of him to reach his level two qualification. There was only a couple of stand out things on his syllabus that he needed to learn about, mainly in depth fork servicing including dampers and SPEED!

The first part was easy as we had a nice old Rockshox Reba from a few years back that had come in for a full strip and rebuild. This fork had the venerable Rockshox Turnkey damper, so not too complicated for Jack’s first go. I let Jack run wild with it, only giving him guidance when he asked for it or got stuck with something. He absolutely smashed it, the fork felt spot on and with that Jack ladled another spoon of confidence and competence into his already on the cusp of bubbling over saucepan of skills. Sorry I’m making noodles as I type this…

The second thing in his repertoire of skills that needs a bit of attention is speed! Now I’m fairly confident that I could leave Jack in control of most repair jobs and he’ll do a decent job of them, the main problem is the time it would take to complete them. This isn’t something I’m majorly worried about, speed will come with knowledge and experience but for Jack it’s something he wants to focus on.

To pass Cytech level 2 in May, Jack’s going to have to complete a timed assessment of a complete strip and rebuild of a bike. A passing grade is 2 hours and 30 mins. This isn’t good enough for Jack though, he’s determined to get a distinction meaning that he’s gonna have to complete a full strip and rebuild in less than 2 hours. This would be a challenge for any seasoned mechanic never mind a newbie dealing with the pressure of an exam situation. Jack’s confident that he’s gonna be able to beat it though so we’d best get practicing!

I was about to start the service on this old Specialized Epic that had come in for the works: new drivetrain, bottom bracket, new cables, new brake pads front and rear, and various other extras.

Jack was bouncing up and down on the other side of the workshop, “can I do this one on my own?! It’ll be perfect practice for my Cytech timed exam!”

Who am I to hamper such boundless enthusiasm? I handed the Epic over and started the stopwatch…

It all went fairly smoothly at first, only very minor instruction was needed for a couple of things and as the clock ticked away it looked like Jack was going to come at least very close to the time he was after, if not under it. But this isn’t an examination on a bike with no use on it, which is what Jack will be dealing with for his actual exam. This is a bike with 15 years riding on it already. In fact the bike is only a year younger than Jack himself!

The fact that this bike is almost old enough to vote was always gonna bring a few niggling issues that are a nightmare to fix for even the most experienced mechanic, never mind someone who was still in nappies when most of these parts went out of production. The clock reached the 2 hour mark just as Jack was doing his final checks and by the time he turned it over to me it had just crept past 2 hours 15 mins! Still an absolutely valiant effort and definitely worthy of commendation.

There were a few issues though, a couple of damaged aluminium spoke nipples in the rear wheel needed replacing and the rear brake had a few different issues. The lever piston was long dead, as seems to be the case with just about all the old Avid Elixir levers we come across nowadays, and the rear caliper pistons were refusing to retract uniformly into the caliper.

The caliper pistons weren’t too much of an issue. A good bit of working them in and out combined with cleaning the built up scum off and adding a bit of DOT fluid to keep things slippery had them firing properly after a while. Meanwhile the broken lever pistons took a bit more work.

The cheapest I could find a lever rebuild kit for was £18.00, which when you add a bit of labour for fitting the kit and rebleeding the brake is way more than the cost of a basic Shimano mt-410 brake or something similar, which will be more reliable and most probably work better than this old Elixir ever did. But we like fixing things at Happy Days and we have a giant box of old brakes which also have their own issues, so with not too much rooting about Jack had found a matching set of Avid Juicy levers that were in great shape to take the place of these tired Elixirs. Once the levers were fitted, the brakes bled up nicely.

The the final boss battle between Jack and this bike was to replace the broken spoke nipples and get those wheels trued up without the rest of the nipples crumbling to dust.

It’s one of my (and just about every other bike mechanic in the world’s) most hated tricks by bike companies to fit aluminium nipples to the wheels that come stock on their bikes. It gives manufacturers a chance to cut a fair chunk of weight for very little cost and they can make them pretty colours but for anyone who doesn’t live in the endless sunshine of California they’re just a recipe for crumbly nipples and snappy spokes in no time at all. Either way a bit of linseed oil on the remaining nipples and some TLC from Jack when replacing the broken ones and he soon had the wheel spinning smooth and true again.

So Jack’s strip and rebuild was done, we’re gonna count it at 2 hours 15 mins and give him a bit of a pass on his brake and spoke issues. He’s still got until the end of May to practice and get it down by 15 mins for that distinction! We’ll be offering a heavily discounted labour rate for a full Jack strip and rebuild until then so Jack can get some practice in, so if you want the full apprentice treatment for your machine (fully checked by a qualified mechanic afterwards!) come on down to Happy Days!

Next up on the list for this month: some new(ish) tools that I like, and one that I thought I’d like but in use was pretty disappointing.

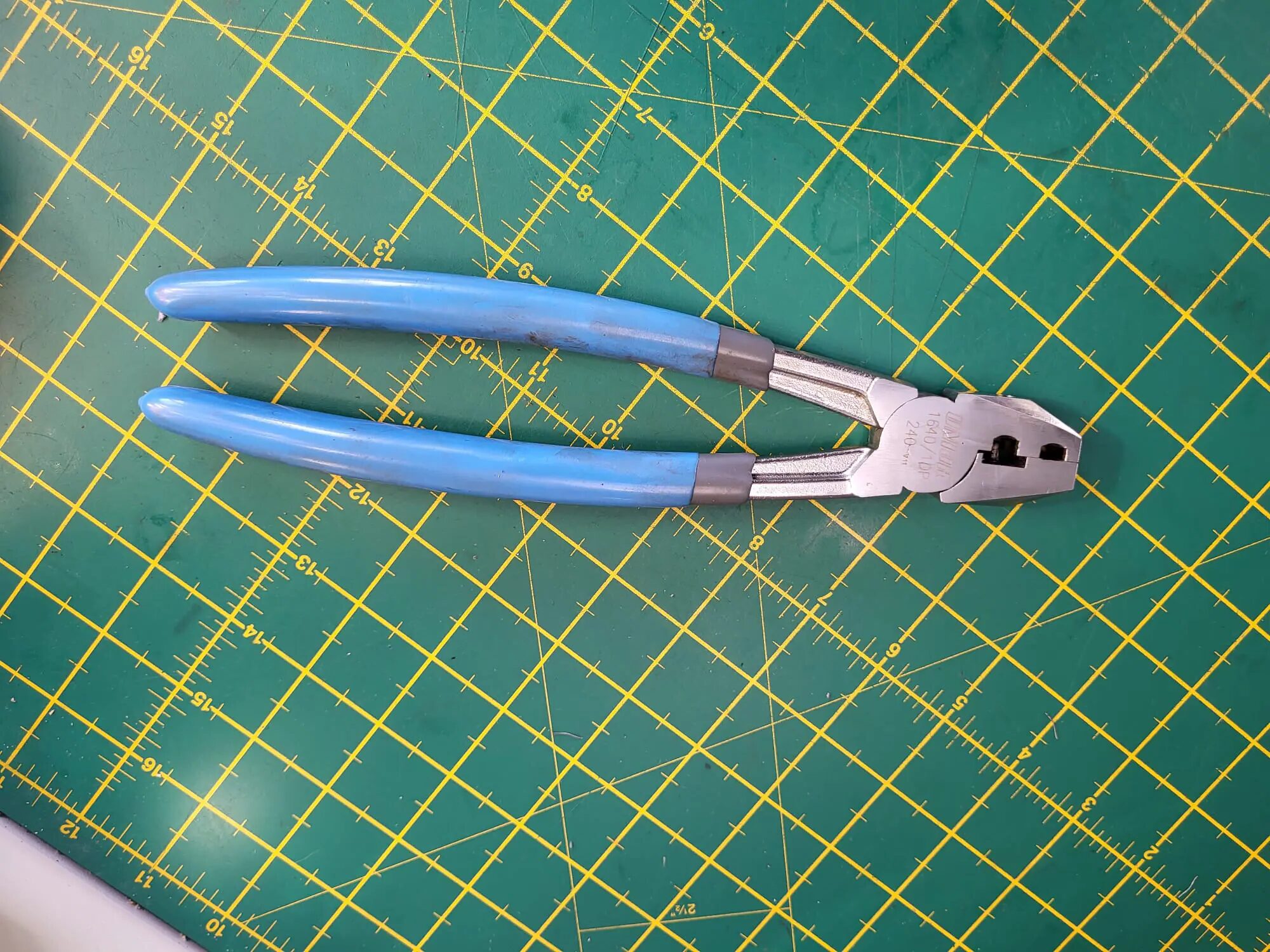

First up is these rather uniquely shaped pliers I found while looking for a better option for fitting cable crimps than my old set of cheap flush cutters with a hole drilled through the jaws.

I like to make sure I always fit cable crimps with the same pattern on the crimp every time. This helps let me know when I’ve worked on a bike before and gives me some accountability in the (thankfully very rare!) case of any problems with a bike that we’ve worked on. Not the most essential thing in a small workshop like ours but can definitely be helpful working in shops with multiple mechanics.

Anyway I came across these in the fishing accessories section on ebay and for the few quid they cost thought they must be worth a punt. After they turned up I was pretty impressed with the build quality. The pivot swings nice and freely with just the right amount of resistance, and the steel used in their construction is easily on a par with much pricier tools in my box.

The handles could use a bit of work in the ergonomics department. While they do have a dual density construction which you’d hope would make a more comfortable grip, it seems that they missed the memo about having a hard and soft section in their choice of rubber durometer and instead plumped for, hard mixed with slightly less hard but also it has spikes…

I am however, willing to forgive any minor discomfort in use for the perfect endlessly repeatable stamp that it leaves in every cable end I fit with it.

It has slots for two sizes of fishing crimps but only the larger of the two comfortably fits a bike cable end, the lower half of the jaw cradles the cable end and make it easy to get into tight spaces without dropping it on the floor. And did I mention the perfect stamp it leaves EVERY TIME!

Anyway if you want one for yourself, how about Park Tools‘ new specific cable crimp pliers? You should definitely get those even though they cost way more and (purely subjectively) don’t leave as nice a stamp in the cable end. Yeah you guys get those so I can keep my unique crimps unique! Why did I even write about these?!

Next up is another interesting looking plier from Unior, I spotted this chain rivet plier on Unior’s website a few months back and was instantly interested as I love it when I know a new tool will be able to speed up my workflow.

99% of chains nowadays are joined by split links and reaching for the chain tool, spinning the handle out, spinning it back down, aligning the pin, then screwing it through, then undoing the tool, then putting it back in the box… It’s all far too much work for a busy mechanic in 2023. We’re living in the future now! And that’s where the Unior Chain Rivet Pliers come in. Simply place the chain in the jaws, make sure it’s straight, and squeeze away. It pushes the pin through the chain to the exact point where a slight sideways flex of the chain will smoothly decouple it. I’ve only had them since the start of January but I’ve thoroughly tested them on everything up to 11 speed chains and so far they’ve worked flawlessly.

Like the crimp pliers, the ergonomics could do with a bit of work, but again for how well they do their job I’m willing to forgive having to squeeze a bit harder than I’d like to. They also work a treat when we get a bike with a drivetrain that looks like it’s been lubricated in grease and tar. Just move the scrap bin under the bike and chop that chain away at a nice, contact free distance!

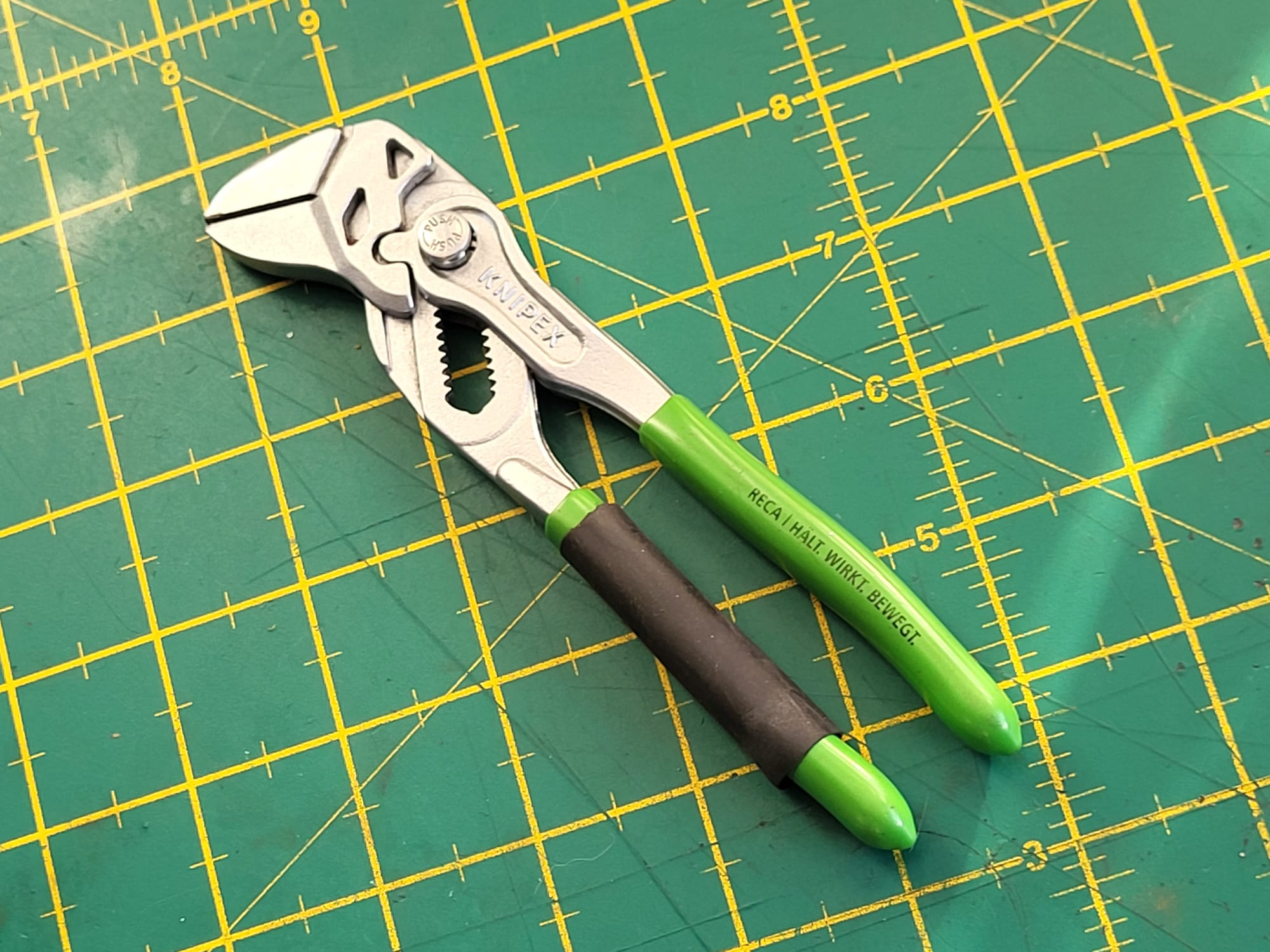

Next we’re back onto the Knipex pliers wrench I talked about last time, firstly to thank @doomanic that left a comment last time I talked about them with that crazy underpriced deal for the 180mm versions with the comfort grip handles at RS Components, I bought 4 sets! (Not all for me, one for my dad for Fathers’ Day and one for Jack when he started his apprenticeship!). And I’m sure many other Singletrack readers snapped some up too because a day or so later they were right back up to full price. Hope no one got in too much trouble for our collective gain!

Anyway while I was still waiting out the eternal delivery time of those pliers wrenches and scouring the internet for tools after a few adult beverages I came across these beauties. I present to you, made by Knipex for Reca tools, the limited edition 150mm GREEN PLIERS WRENCH!

I definitely shouldn’t be allowed access to my card or the internet when I’m at any slight level of intoxication because even though I had four sets of 180mm pliers wrenches already on their way to me I ended up spending more than I’d spent on all four of those on one set in the 150mm length. Purely because it was green. I like green tools.

With the help of a bit of heat shrink it became black and green to match my hair because colour coordination between tools and hair is obviously essential.

Thankfully however it turned out this wasn’t just meaningless drunken splurging. This 150mm pliers wrench has become my absolute favourite to use from my expanding collection. The tactile feedback and extra room to manoeuver afforded by its slightly smaller size is really noticeable, especially for jobs where you have limited space, or for tightening up hydraulic hose fittings. Which strangely enough brings us to our next tool..,

This ratcheting flare nut wrench is one I’d seen Dave Rome @romeandstuff talk about in an article a while ago and I really liked the idea of it. Again it seemed like something that could help speed up my workflow. Not having to slide the wrench off the compression nut every turn could save me several whole seconds on every brake fit.

Sadly in use it’s a bit fiddly with the ratchet mechanism needing adjustment by hand to release the tool after use, so it sits in my box almost unused while my 12 year old Park Tool non ratcheting version is still in daily use. If it ain’t broke I suppose…

Now I’ve gone on for quite a long time already. I know I said at the start about a story about some hammers and stuff as well but I’m all full of noodles and I’ve already rambled on way over my brief so I reckon it’s probably gonna have to wait for next month.

How’s that for building suspense…

Hammers! Come back next month for more hammers than you could shake several sticks at, and sticks you could use to make hammers! Maybe some other general ramblings as well, who knows!