In association with Ison Distribution

If you’ve not already read it, Part 1 of this feature can be found here.

Last time I took you, dear reader, into the world of Ison Distribution and their own brand of UK designed and tested components, Gusset. As I continued my closely monitored journey through their Bond villain-esque lair high in the snow-capped mountains of some unspecified European country, my every move subjected to the scrutiny of suitably shadowy henchmen, infrared scanning and sub-cutaneous tracking devices (or perhaps just a warehouse down in the heart of Cambridgeshire), I happened upon row upon of boxes of Halo wheels. Literally stacked to the rafters, it’s a scene not unfamiliar to fans of Indiana Jones. Except in this case instead of wrath of God type shenanigans, there are wheels for pretty much every budget and every type of rider.

Halo are the in house hub and wheel brand of Ison Distribution. Established back in 1995, they have worked hard to establish a reputation for value and performance in a brand where the focus is very much on design, development and testing being rider led, both in house and through their sponsored riders. At the heart of Halo are Jordan Lunn (no, not THAT Jordan Lunn of The Collective fame), Sales and Marketing Manager for Halo and an accomplished 4X and dirt jump rider at international level who has more than his fair share of experience when it comes to knowing what works and what doesn’t and Ryan Griffiths, a sport technology engineer with a Masters in Advanced Mechanical Engineering who commutes 23 miles each way each and every day on his time trial bike. Usually in under an hour. The git! Known affectionately as meat bats on account of the size of his thighs (Even Chris Hoy would get an inferiority complex standing next to him), every Halo design passes through him.

Completing the team is a mysterious figure we shall only refer to as Maz. A shadowy figure, Maz (allegedly short for Marigold) is a serious petrol head, the Ducati 916 in a quiet corner of the factory and the soon to be classic Fiesta RS Turbo in the car park testament to this. More importantly, he is the guy who takes the finished parts and builds them into wheels for you and I, the customer. If you call up ISON with a technical wheel related question, the chances are that it will be Maz who you will speak to. Think of them like Charlie’s Angels – albeit without the big hair, figure hugging cat suits and questionable choice of footwear.

Wheels built the old fashioned way.

In days past, it used to be the case that if you wanted a set of wheels, there was really only one option and that was your local wheel builder. Select your rims, spokes and hubs then asking them to work their magic before presenting you with something pretty special. Hand built wheels definitely had a cachet to them. However, with factory built wheels coming to dominate the market, there is a perception amongst many consumers that most hubs, rims and spokes are bought out of a catalogue and off the shelf of a faceless factory unit somewhere in south east Asia. You could be forgiven for thinking that an awful lot of wheelsets are distinguished only by their sticker. It is a perception that Halo are keen to counter with their hubs, rims and wheel sets being designed, developed and tested here in the UK. Design that works is very much their raison d’aitre.

To help me understand what makes Halo stand out from the competition, Jordan and Ryan took me through the design process for their latest wheelset, the Vortex. Designed as a wheelset that can stand up to the rigours of elite level Enduro World Series races, week in and week out, work on the design started in 2016. I’ll leave it to Jordan to explain.

“Back in 2016, we realised that our trail focused Vapour 35 wheels were being used for full on Enduro racing. They weren’t designed for that thus we decided to set about designing and building a heavy hitter wheel that was still reasonably lightweight and affordable. We knew the demand for an Enduro specific wheelset was there so Ryan and I started playing about with some ideas. We started with our Supadrive hub design. This has been some ten years in development to reach the current iteration and we believe that it offers some significant advantages over traditional pawls based hubs.

Unlike a traditional pawl hub, our heat treated pawls each have 12 micro teeth in them which dramatically increases the surface area in contact with the free hub body thus spreading the load. Biting into a drive ring that has 120 points of engagement, it offers near instantaneous engagement. In fact, it is even quicker than a Chris King hub! The big advantage of this design is that it is better able to withstand the additional loading that comes with wide range cassettes.”

I stop to ponder this last statement as I am reminded of an incident where I was left some twelve miles from home at the top of the Campsie Fells when my rear free hub (I shall spare the manufacturers blushes here) decided to fail in spectacular fashion leaving me with a very long walk home. More reliable is definitely a good thing in my book.

Future proofed.

“The axles are steel which helps reduce flex while we now incorporate 2 steel inserts in the free hub body which eliminates the issue of cassettes digging into the free hub body. One other feature which we are particularly proud of is for the ability for our customers to adapt our hubs to different frames. QR, bolt thru and boost are all taken care of. We believe that as standards change, our customer should be able to use the same wheels without having to spend a fortune on adaptors. For example, you can change to Boost by buying our adaptor kit which only costs £20. It even includes longer disc bolts. We want to keep our customers happy and this is one of the ways we like to do that.”

So what about the rims then? I ask.

Stepping into the office, Ryan takes me through the design process from initial idea through to final tested product.

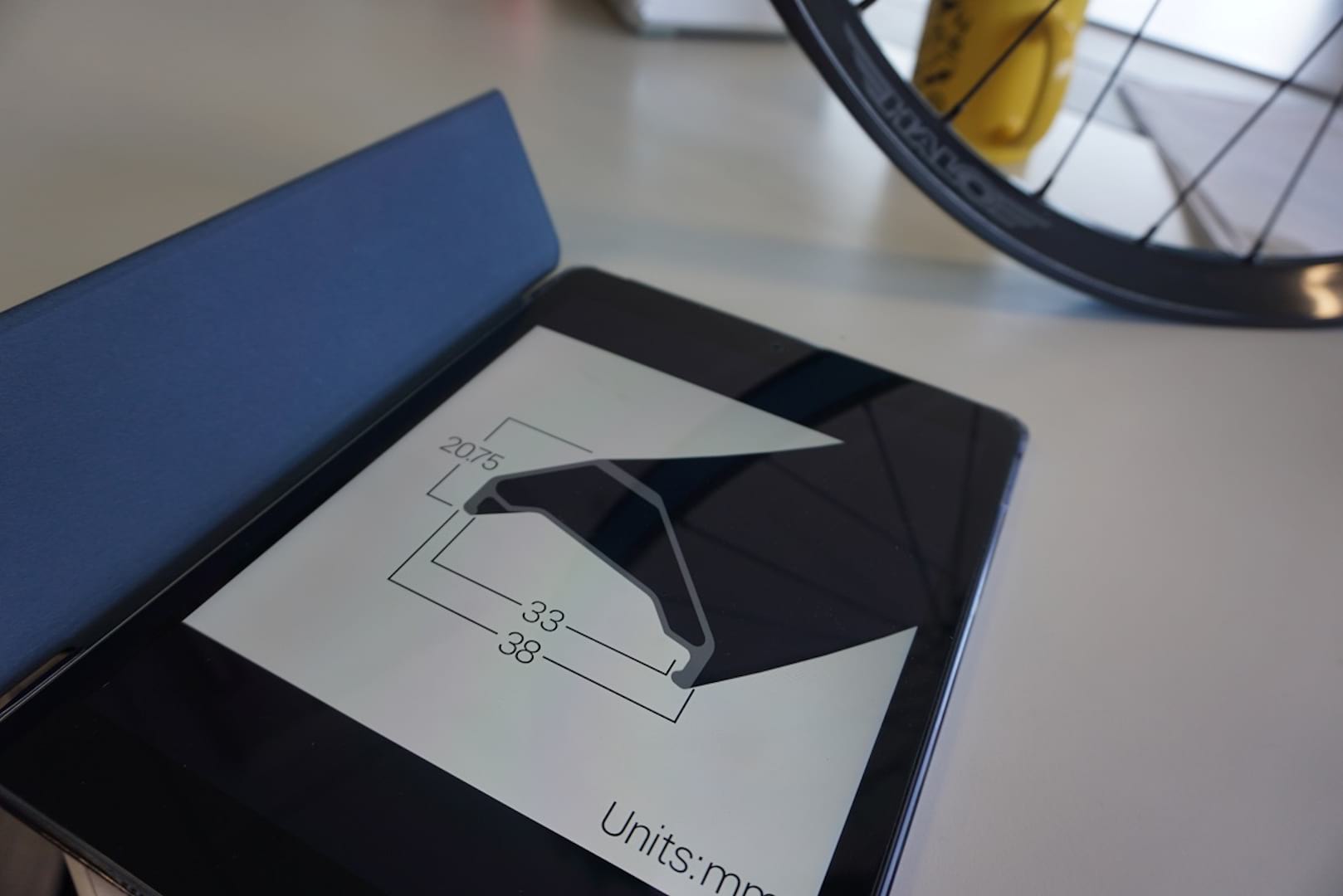

“With our CAD software, we are able to design and stress test rims using finite element analysis without having to go through the expensive and time consuming process of running multiple versions through the mould. Running a rim through a mould to create a working prototype can cost several thousand pounds whereas with our design and testing software we can accurately predict how a design will perform. Only when we are happy with the design do we then produce rideable prototypes.

With the Vortex rim, we opted for an asymmetric design as this allows us to use equal spoke tensions thus building a stronger wheel. Through our software, we were able to play about with the design, shaving excess material where it wasn’t needed but adding it where it was.

Wall length and thickness have been optimised so as to cope with the inevitable impacts that are unavoidable when riding hard and fast in an Enduro race. Throw in eyelets , brass nipples and traditional J bend spokes for ease of repair at pretty much any local bike shop and you have wheels that are designed to be ridden and ridden.”

Carbon schmarbon.

Turning to Jordan, I ask about the decision to use aluminium rather than oh so on trend carbon that seems to dominate the high end wheel market.

“We have tested both off the shelf and branded carbon rims over the last three years and have concluded that nothing comes close to matching heat treated aluminium in terms of impact resistance, value for money and recyclability.”

And with this, he scuttles off coming back moments later with a pre-production rear Vortex rim that has been raced and trained on by team rider James Shirley over a number of Enduro World Series races, in training and in Whistler. It wears its battle scars proudly. The rim is dented, dinged and scratched – to be blunt, it looks like it is completely fubar’d. And yet put a tubeless tyre on it and it still holds air. All the more remarkable is what happens when I place it on the ground. It is still completely true. Colour me impressed.

Jordan and Ryan are clearly proud of their design and the fact that it has held up despite what you might call a very long paper round. It’s hard not to be impressed by their commitment and desire to make a product that will stand up to abuse and isn’t just a one season wonder. As Jordan explains

“Mountain bikes crash – a lot. Having tested all make and manner of carbon rims, none of them worked in a way that we would be happy with. Rims will inevitably smack into a rock, get scratched or dented. Carbon works on the road but for hard off road riding, we don’t see the value in using carbon. You would have to destroy three pairs of our wheels before you had spent the equivalent to replace a single high end carbon rim.”

I have to admit that he is preaching to the converted at this point. I’ve never been a fan of carbon rims for hard charging mountain bike rides, truth be told. While they do offer perceived advantages in terms of potentially reduced weight and increased stiffness, they come at a significant additional financial cost. Moreover, while stiffness seems to be the Holy Grail for pretty much everything these days, the reality of riding wheels that are optimised for stiffness means that comfort takes a back seat. Now I don’t know about you but saving a few seconds on a ride isn’t worth the trade off of feeling like I have been dragged through a hedge backwards then dropped down a flight of stairs. Nope, I’ll take the comfy chair thanks. Moreover, I’d rather have a bent rim that I can ride home than one that has collapsed.

The dark art of wheel building.

Arguably saving the best for last, Jordan introduces me to Maz. With a smile as wide as the Clyde, it would be hard to imagine anyone not liking Maz. He has an infectious enthusiasm for what he does backed up by many years of experience in building wheels. If you were to buy a set of Vortex wheels, it would be Maz who built them. If you phone Ison and have a question about your wheels, it will be Maz you talk to.

Setting up my Go Pro on time lapse, I set Maz the challenge of building a wheel there and then. Like a shot, he is off. I watch with genuine envy as he makes the art of wheel building seem, in the words of Blackadder “simpler than the simplest simple thing that has ever been simple!” Methodical and careful in his approach, the speed at which he transforms a pile of parts into a wheel that is true and ready to go is astonishing.

I suspect he could do it blind folded if he was asked to. Within a matter of minutes, I have a brand new wheel in my hands that is ready to be ridden. All that is left to do is apply one of the six different coloured decals to the rim, fit a tyre, give it a pump and then hit the trails. Simples!

To add a neat finishing touch, there is even the option of Halo’s tubeless valve kit. To be fair, it looks not dissimilar to every other tubeless valve out there but as I have now come to expect, the devil is in the detail. How many times have you tried to remove a valve core for a tubeless set up and ended up rummaging through the tool drawer before settling upon a spanner? To avoid the subsequent swearing that almost inevitably follows on the trail when you realise you forget to tighten the valve properly, Halo have included a tiny threaded tool that you have no excuse to leave at home. A couple of grams of red anodised genius!

And with that, my journey into the world of Halo wheels is over. So what do I make of the experience? In Jordan, Ryan and Maz , I see a genuine passion and commitment. They are clearly very proud of what they do, their products and the real world testing that goes into them. I wonder how many manufacturers would happily display the results of real world testing to a journalist such as myself? The rim they showed me was battered to the point that it should have been un-rideable yet it was still true. With Halo, I think there is a genuine desire to make products that will last and which will keep you rolling despite the occasional dent and ding that is almost inevitable when riding a mountain bike hard. It’s refreshing to realise that Halo is an example of rider led product design that recognises that not everyone has the bottomless pockets of sponsors to keep them in parts. It’s easy to make wheels where the budget is limitless. Making wheels that last without costing the Earth is where the real art lies. From what I have seen of the Vortex, I reckon they might just be onto something.

Next time I take a trip into the wilds with Duncan from Surly to see how a man from the flatlands of Cambridgeshire copes with the mountains of Scotland.

Disclosure:

This feature was produced in association with Ison Distribution

A nice article and I’m sure they will be a brand people now consider along with or instead of the ususal suspects. For me personally I’d take aluminium over carbon anyday for serious shredding. Yes maybe carbon for XC if your pockets are deep enough or if you’re sponsored. let’s be right though there are some dam good lightweight aluminium wheelsets out there.

I recently bought some Halo wheels and they are excellent and rather ‘andsome. Had a question and Ryan emailed me back the same day. Definitely a brand people should consider.

ps. Link to the wheelbuild video?

Long before I was asked to visit ISON, I tested a set of their Halo Vapor 35 wheels and was genuinely impressed by them. They were a really solid set of wheels which managed to withstand my abuse. I like the fact that they design in the UK and were happy to show me rims that had clearly been flogged pretty much to destruction. The personal touch that DezB mentions strikes a real chord with my experience of visiting the team.

Sanny