Back in February for issue 117 of Singletrack Magazine, we decided to see if a self-confessed perfectionist who’s terrible at woodwork make a bamboo bike from scratch at home? Well, the answer is ‘sort of…’

Read on for the full story and watch out for the great membership offer at the end.

Words: Wil Photography: Chipps

Sand a little bit. Stop. Step back, blow away the sawdust, eyeball the mitre. Nah not quite, needs a bit more. Start sanding again. I can feel the coarse sandpaper starting to make its way through the third layer of skin on my fingers… try to ignore that. Stop sanding to check the mitre again. Do that thing that artists do where they cock their head to a few different angles while looking at something. Squint a bit, then nod. Yeah, reckon that looks alright now. Take the long piece of bamboo over to the jig and check how it’s fitting up against the shiny alloy headtube. Still nice and snug. A beautiful fit. Pretty impressed with that really, given it was the very first mitre I’ve done in my life. Now, check the other end of the downtube where it meets the metal bottom bracket shell. This is the one I’ve been sanding into the tube for the past three quarters of an hour. It kinda fits, but then I look around at the other side. As in, the underside of the bottom bracket where there’s a rather large gap. Hold on, that… that doesn’t look right. No, it is most definitely not right. I start to panic. The whole mitre is off-centre. Like, by a good 30 degrees. And there’s an enormous gap between bamboo and metal that I can fit my finger into. That is not what the instructions specify. ‘Shit’ I think. Shit-shit-shit. Then I realise – if that mitre isn’t good, I can’t fix it. My neck starts to get hot. This whole tube is… oh shit. Oh f***! F***ITY-F***-F***!

Yep, that tube is toast.

That’s me coming to the realisation that I had just royally cocked up the second mitre on the first tube of the first bamboo frame I’d ever endeavoured to build. The tube was ruined. Unusable. A throwaway. Given all the cutting, mitreing and gluing I had ahead of me, this didn’t bode well.

Why bamboo?

That my friends, is a most excellent question. And one that I’ve been repeatedly asking myself during the past month of turning a Bamboo Home Build Kit into some sort of semblance of a rideable mountain bike.

Notwithstanding the torture I’ve put this collection of tubes through, bamboo itself is an incredible material. Aside from the fact that it just magically sprouts up from the ground, bamboo can be, and is, used for a huge variety of purposes – from food for cuddly pandas and as an ingredient for making beer, through to being used for scaffolding and as a building material for furniture, roads and bridges – it’s versatile, and a whole lot more sustainable than most human-made alternatives.

It’s also surprisingly tough. As I’ve been informed (and reassured) by the guys at the Bamboo Bicycle Club, some species of bamboo actually have a higher tensile strength than steel, while also having a higher compressive strength compared to wood, concrete or brick. So yes, it is more than strong enough to build a mountain bike frame from. Well, with one important caveat… It is strong enough providing you build it correctly.

Despite all of these reassurances though, bamboo still seems like an odd choice to use for a mountain bike frame. After all, what was wrong with steel, aluminium, titanium and carbon fibre? They all do a pretty good job don’t they? This question has proven to be just as perplexing to the experienced cyclists as it has been for the non-riders who have come across my recent framebuilding project.

“There are a few reasons,” explains James Marr of the Bamboo Bicycle Club, when I ask him why bamboo. “There’s no faster way to build a frame with so few tools and so little expertise required – anyone can do it.” This is a valid point, because not all of us have a TIG welder kicking around in our sheds along with an assortment of correctly sized steel tubes and cutting tools. To make a frame out of metal or carbon fibre you need a lot of specialist tools, and you need a healthy amount of skill and experience too. When it comes to bamboo though, all you really need is a saw, some sandpaper, a few metal bits and some glue. And – at least theoretically – even a halfwit like me should be able to build a frame out of bamboo in their own home.

Lollipop sticks? Seriously? I’m going to be sitting on a saddle and seatpost that’s supported by lollypop sticks?’

I arrange the three bigger bamboo tubes over the technical drawing that’s printed 1:1 on the paper underneath. The front triangle is actually starting to look… like a triangle. Two weeks behind schedule, and print deadline’s looming, but at least I’m starting to get the hang of this mitreing business. Or am I? Time to cut the seat tube to length. Sawing this stuff by hand without a vice is time-consuming business. Follow the line I’ve free-drawn over the masking tape, and position the tenon saw. Pull back. Watch sawdust spit out either side. Lift. Reposition. Pull back. More sawdust. Lift. Reposition. Pull back. Try to avoid the other end of the tube from swinging around on the table. Keep going until one tube becomes two. Somehow I haven’t cut all my fingers off. Yet.

Right. The front triangle needs tacking soon, but I’ve gotta jam this metal sleeve inside the bamboo seat tube. The sleeve is wibbly-wobbly inside the bamboo. Check the build manual. It says that this is what the ziplock bag with the dozen sachets of epoxy and lollipop sticks are for. Huh? A little wooden lollipop stick to shim out the metal sleeve?

Cut open the epoxy sachet, get mixing, and jam away. There are mere minutes before the epoxy dries and the sleeve is stuck in place. No need for scepticism – the lollipop stick does the trick. Except, what side of the tube did that stick go into? Hmm. That’s going to be an interesting saddle angle.

*sigh*

Joining the club

Deep in the heart of London you’ll find the small workshop that’s home to the Bamboo Bicycle Club. Officially opened in Hackney in 2012 following two years of bamboo-related learnings, Bamboo Bicycle Club is less production facility and more community workspace.

The company is run by James (an ex-wind turbine design engineer) and Dan Sinha (ex-aerospace designer). After experimenting with his own bamboo creations, James decided to leave his engineering career behind to pursue one in the bicycle industry. But unlike many others who take the leap into the bicycle business, James didn’t want to just make and sell stuff to other people. Instead, he wanted to help others to make their own frames.

“In terms of a framebuild, it can take a day,” James informs me. “We run our workshop over two days so there’s some wiggle room.” This surprises me. I reckon I spent a whole day just staring at the opened box of bamboo tubes. Sweating.

For most people, their bamboo frame will be built over a weekend under the guidance of James and Dan in the Bamboo Bicycle Club workshop. Here they have all the tools, equipment and know-how to help guide each person through their own framebuilding experience. You can choose to build a road bike, a commuter bike, a mountain bike, or something more unusual. “I would say we’ve almost done every style of frame: fat bikes, tall bikes, cargo bikes, e-bikes, we did a longtail fat bike, and a mini-velo cargo bike,” says James. “We’ve made aero track bikes [most notably for the Design Museum – Ed], steadfast tourers and trendy thru-axle gravel machines.”

A weekend workshop session will set you back just under £600 (inc. VAT). You’ll walk in there on Saturday, and on Sunday you’ll walk out with your own custom-built frame. Most people would struggle to learn how to weld a single steel tube in a weekend, let alone build a whole frame in that time [I concur, says Not Very Good At TIG Welding – Ed].

The accessibility of the bamboo framebuilding course has been such a success for the Bamboo Bicycle Club that James decided to take the concept beyond the workshop. In 2014 the Home Build Kit was launched.

“We had a lot of interest from around the world; people saying they wished they could make it to the workshop,” James explains. “So we tried to come up with a solution that still gave a lot of support and a great result regardless of the experience levels of the builder.”

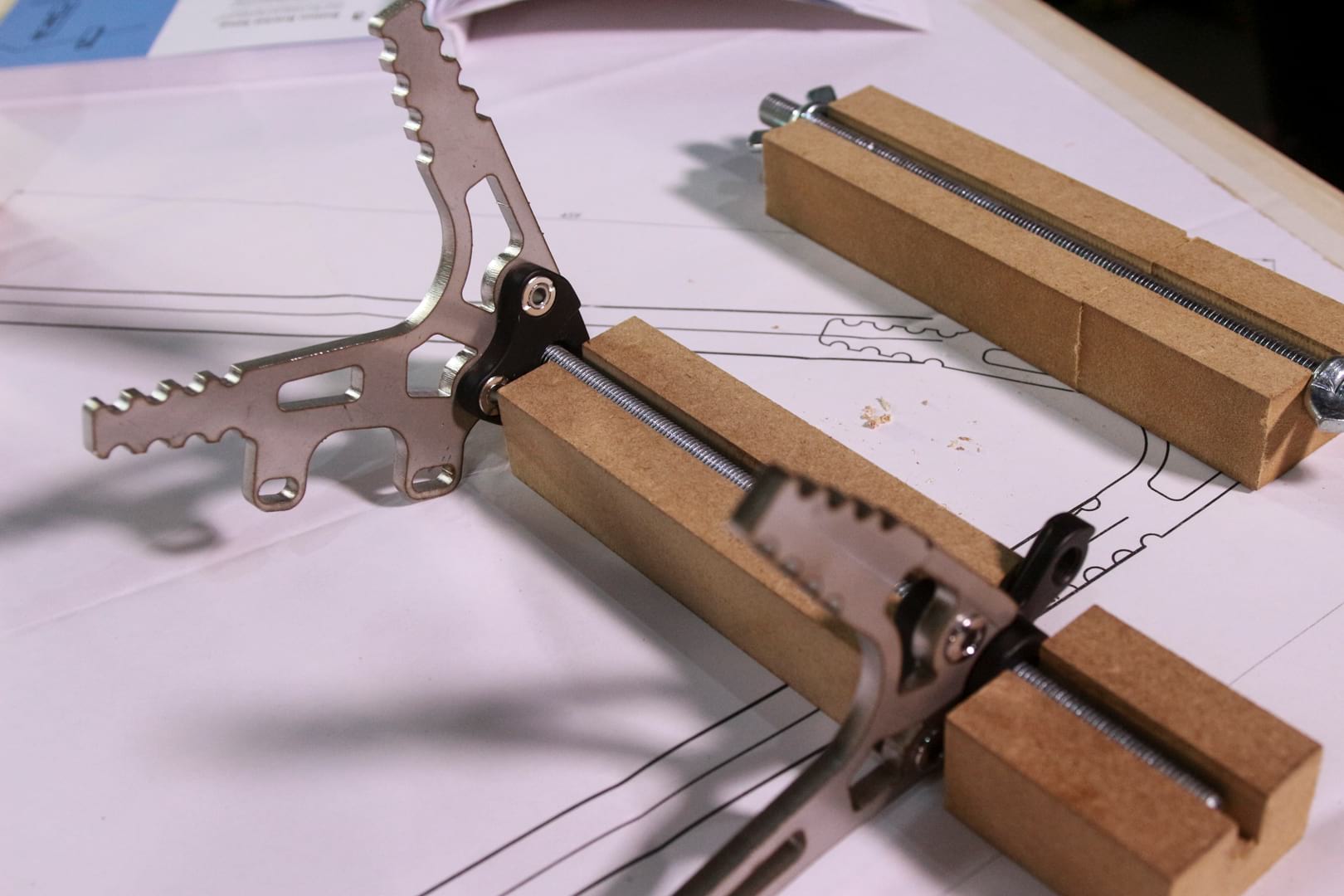

James and Dan spend most days during the week preparing pre-fab Home Build Kits, which are packed up and shipped directly to the customer’s door – wherever in the world that might be. Inside the Hello Fresh-style box are all the necessary lengths and diameters of bamboo (plus a few spares), which are sourced from either within the UK or further afield in Europe or China. The metal components are custom-designed in-house and manufactured in the UK, with the thick steel dropouts in particular being a unique item requirement for the bamboo tubing. There are bottles of epoxy, some sandpaper, a load of hemp fabric to use for the bindings, and your frame schematic that’s printed out on a big A0 sheet of paper. To guide you through the process there’s a beautifully illustrated manual, which is supplemented by the Bamboo Bicycle Club’s helpful online video tutorials.

‘How many more of those tubes are in there?’ I wonder. I peer into the cardboard box that my bamboo kit came in. I know we’ve got spares, but I’m starting to wonder if I’ve got enough spares. The smallest tubes are harder to work on. Dang. Just ruined another one. Bloody angle wasn’t right, and that length is too short for the chainstay. Bend down, grab another small-diameter bamboo tube that will hopefully become part of the four-piece chainstay yoke. A complicated junction. ‘Why did I have to spec such short chainstays? And 2.8in tyres?’ I am now actually talking to myself out loud. ‘What a f***ing idiot’ I tell myself. This whole area wouldn’t have been so fiddly if I hadn’t gone for such cocky specs. I feel my internal anxiety levels rising. Deadline is getting closer, and the second diamond in my double-diamond frame is still in my hands. In incorrect sizes and lengths. The time to be precious about every tube mating up perfectly with no gaps is long gone. The only thing left is to just get it done. And cross fingers.

Is it easy?

I’ll be honest. For me, no. No, it was not easy. But I’m possibly the Bamboo Bicycle Club’s worst candidate for a Home Build Kit. One, I’m a perfectionist. And two, I don’t know anything.

Early on I took a lot of time doing things that didn’t need to be absolutely perfect. As James explained to me, it takes a lot of experience of working with bamboo before you can get each joint nice and smooth, so expect there to be a few gaps here and there. Overall it’s quite an organic process, and there’s a reasonable amount of margin for error – more than you’d expect.

I also don’t have any experience with woodwork in the first place, and I’m just not the sort of person who possesses tools and the motivation to whisk things up in the shed. I can service forks, bleed disc brakes, and build a wheel, but beyond bikes, I’m practically useless.

Oh, and I didn’t really read the manual all the way through first. I’d highly recommend that.

We did have some preliminary difficulties with the frame jig, as it was a prototype kit designed for the Boost drivetrain spacing I was building the frame with. The Bamboo Bicycle Club doesn’t yet offer these dropouts as a standard option with its mountain bike kits so there were a few delays getting the jig right, which added to the building stress.

In hindsight, my custom frame geometry was a little too ambitious. A very short 420mm rear centre length with clearance for 2.8in tyres is a challenge for most brands that make frames out of metal in big Taiwanese factories. And I was going to attempt that with bamboo, a saw and some epoxy? I indulged in some artistic licence and ended up lengthening the rear centre mid-build to give me more room between the tyre and the chainstay yoke, which is why the frame looks like it has turkey legs poking out from behind the bottom bracket. Distinctive? Yes. Poorly adapted on my behalf? No doubt. Next time round, I’d surely go for something simpler. A cross-country singlespeed, or a laid-back commuter perhaps?

There were a few points during the build where I just wasn’t confident in a join, or a particular cut, or whether I’d wrapped the epoxy-soaked hemp right, and this is where I can see the appeal of doing the build under the guidance of James and Dan in the Bamboo Bicycle Club workshop. I like the idea of having someone there to say ‘nah that’ll be fine’, or ‘oh my God, what are you doing?’.

‘Urgh! It’s disgusting!’ My nose wrinkles and I recoil slightly at the sight in my hands. Gloved fingers are pinching a strip of hemp, saturating the fabric with epoxy as I run my fingertips from the top down to the bottom, collecting and expunging big gobs of translucent epoxy along the way. If anyone was to walk in now, I imagine it looks like I’m harvesting alien eggs in a ghetto laboratory. The two-part epoxy has been reacting for about 20 minutes now, and it’s quite warm in my hands. It’s a weirdly enjoyable experience, while also being very, very messy. I think I’ve ruined my new shirt.

The finished product

After the glue had dried and I managed to peel off most of the electrical tape that’s used to compress the epoxy-soaked hemp joints, there’s a bit of sanding and cutting required to remove the excess hardened resin. At this point you could potentially tidy up and varnish the frame, or prime and paint it whatever colour you like. I choose to leave mine raw, not because I’m an aesthete, but rather because I’m desperately running out of time.

For my bike, I built it around a 140mm travel Manitou Magnum Plus fork, Sun Ringlé wheels, and 2.8in Maxxis tyres. The rest of the kit is a mish-mash of test parts that I scrabbled together from spare bits in the office, including a 1×11 drivetrain, a Funn cockpit and some Shimano Zee brakes.

I’m sure you won’t be surprised when I say that there were a few key issues with the build. The main problem was with clearance between the crank arms and the chainstays. By that I mean, there was none.

The chainstay yoke was so wide to clear the big rear tyre that the bamboo tubing ended up square in the firing line of the cranks. I managed to bodge a solution that involved fitting a much wider fat-bike crankset. This pushed the Q-factor out to hilarious cowboy proportions, and it’s also produced a new standard of chainline that we’ll probably see introduced in 2021, but more importantly it allows the pedals to clear the frame.

Once I fitted the rear wheel though, I discovered it was out of alignment with the rest of the frame. Kind of in a way that would complement left-hand turns, but would probably be suboptimal in all other scenarios. Because of this cockeyed rear wheel, the 2.8in rear tyre was a little too intimate with the bamboo chainstay. And by that I mean the rear wheel wouldn’t turn. So off came that tyre, and on went a 2.35in tyre in its place.

Taken it off any sweet jumps?

Bodges aside, the Bamboo Bastard is actually rideable. I can’t say I’ve racked up hundreds of hours of saddle time on it, mostly because the build came right down to the wire, and I only just got the damn thing finished before this magazine had to be at the printers. But I can say that it rides like a bike. In fact, it rides like a really fun bike. It may have been that my expectations were extremely low to begin with, but it handles beautifully and it fits like a glove. It’s quite slack, and it’s also really long, which makes it feel stable. It hasn’t broken yet, which honestly baffles me. I keep expecting the bottom bracket to fall away from me, but so far *knocks on spare bamboo tube* it is still where it’s supposed to be.

It’s also surprisingly silent to ride, and having read other testimonials from the Bamboo Bicycle Club, it’s this smooth and dampened ride quality of bamboo that other bambooists appreciate too.

Oh, and as for weight? Well it’s not too bad. The complete bike clocked in at 13.05kg/28.75lbs, with the bare frame weighing in at 2.55kg. The bamboo tubes are light, but there’s a helluva lot of resin holding that thing together. Needless to say, weight probably isn’t the reason you’d choose to build one of these things.

All said and done, I still can’t quite believe that I’ve just built a mountain bike out of bamboo. Admittedly it’s a bit cock-eyed, and it probably wont bewinning any awards in a beauty contest. But it’s still a bike that I made with my own bare hands. And I think that’s pretty cool.

I’ve certainly learned a lot. I’ve learned the limitations of my patience and skill, and I’ve learned that if you’re not confident with what you’re doing, always seek the advice of someone who has experience. And so if I was to do this again, I would 100% go down to London and build a frame under the guidance of James and Dan, both of whom have both been extremely helpful through this entire process.

Oh, and I’ve also discovered that my iPhone doesn’t recognise my sanded-down right thumbprint anymore. The Bamboo Bastard has most definitely left its mark on me – in more ways than one.

Good stuff!

Reminded me that I’ve been meaning to enquire with them about educational kits/packs to do with my school STEM club. The kids would love to build a bike!

Sounds like fun.

Perfect winter bike when you think of it. Nothing to corrode, and if you crash and break it, just glue it back together.

The ultimate grass tracker. 🙂

Looks great. Nice one Wil

Most importantly, where did you get the panda suit from?

What happens if a panda walks past?