Rotor Components is probably best known for its range of lightweight alloy cranks and oval-shaped Q-Ring chainrings. The Spanish manufacturer makes a host of other bits and pieces like bottom brackets and power meters, and it’s also released a hydraulically activated road shifter system called UNNO. Rotor had all those products on display at Eurobike, but it was the brand new RVOLVER hubs that we were most interested in.

Announced just last week and shown first here at Eurobike, the RVOLVER hubs will be available in variety of different spoke drillings as well as both road and road disc options, and there’ll be a mountain bike version too. The mountain bike hubset will only be coming in Boost spacing (110x15mm front and 148x12mm rear), though you will be able to choose from 28h and 32h options, along with the choice of Shimano or SRAM freehub bodies. The hubs are made from CNC machined 7075 alloy and will be manufactured in Rotor’s facility in Madrid.

The aspect of the new RVOLVER hubs that Rotor is most excited about however is the use of a new clutched freehub mechanism, which is a sort of hybrid between a regular pawl system that comes in the vast majority of hubs. and a ratchet system like you’ll find in a DT Swiss or Chris King hub.

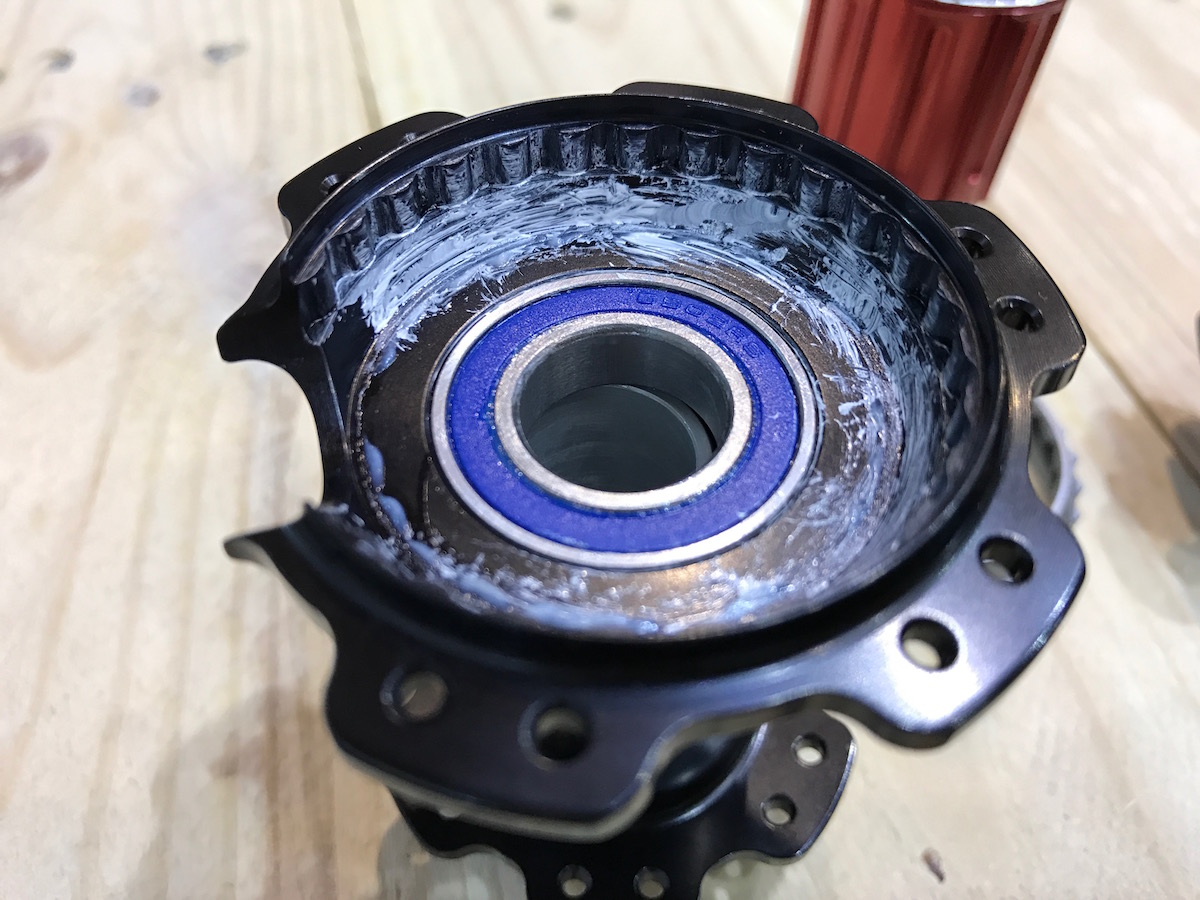

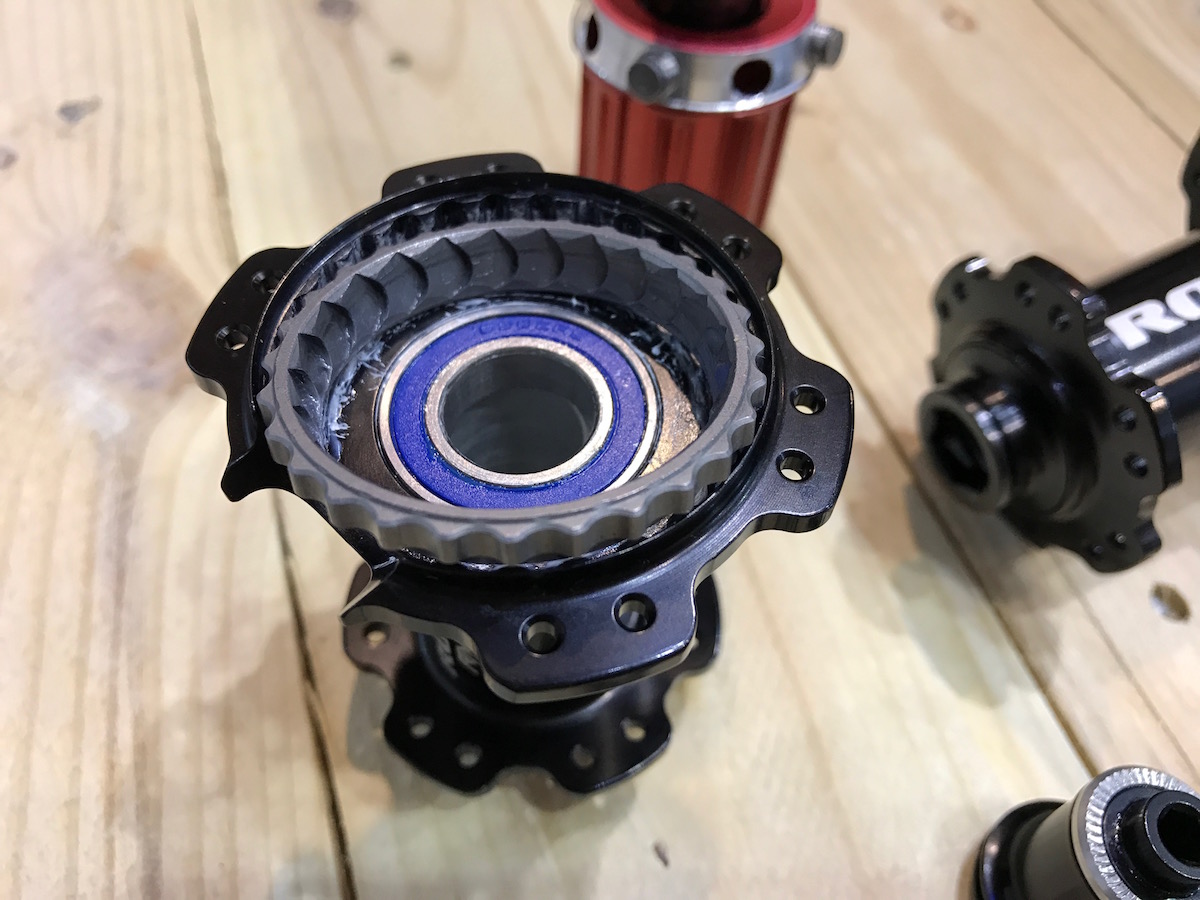

Rather than use an existing design, Rotor built its own. Using a clutch plate that interlocks with four spring loaded pins (the pawls), the clutch plate is designed to retract during coasting in order to lower rolling friction when you’re not pedalling.

While I was at the Rotor booth, I had the chance to film a quick video to show how the system works, which you can watch in the above video. According to Rotor, the retractable clutch design lowers rolling friction by 30% over a standard pawl system. Some other news websites have claimed that friction is eliminated completely, but that isn’t the case. In fact, I could feel quite a lot of friction while rotating the freehub in my hand, with each ‘click’ offering quite a chunky and positive engagement. These were preproduction hubs, so that could change.

You’ll get 25 clicks per revolution, meaning the engagement is 14.4°, so it’s not particularly fast – especially when you consider that other mountain bike hubs on the market offer upwards of double that. However, Rotor is working on an ‘Enduro’ model that’s currently being tested by their enduro racers, which we’re told will offer twice as many engagement points, bringing Rotor’s RVOLVER hub more in-line with the competition.

Rolling resistance isn’t the only purported benefit of the RVOLVER hub design. The hub internals are also dead simple, and with the exception of accessing the freehub bearings, the whole rear hub and clutch mechanism can be pulled apart and serviced by anyone. Rotor also states that the design offers a lighter system, which is likely how they got the mountain bike hub weights down to just 112 grams for the front and 238 grams for the rear – about 40 grams lighter than a DT Swiss 240 hubset.

yeah but what does it sound lke?

@joemmo – there’s a video embedded up at the top of the article, though you’ll need to flick the sound on to hear it properly!

Nicehubs and it’s great to see a different idea. However, unlike DT’s approach, the ‘in/out’ movement of the ratchet ring looks to be supported by the aluminium hub shell on these.

DT use a steel insert, threaded in to the hub shell (the bit requiring the special tool to remove and acces the bearings) to support the ratchet ring.

I wonder if there will be any problems with wear developing between the ratchet ring and the hub shell on the rvolvers?