Would you believe us if we said there’s a sound reason for making ebike specific pedals? No? Well there is, but we’ll get to it in a bit.

German company Reverse Components (part of Solid Bikes) aren’t the first name that springs into people’s heads in the UK when you say “bike bits”, but they had a significant presence at Eurobike, with plenty on show. We had a quick chat with them and picked up an interesting few tidbits.

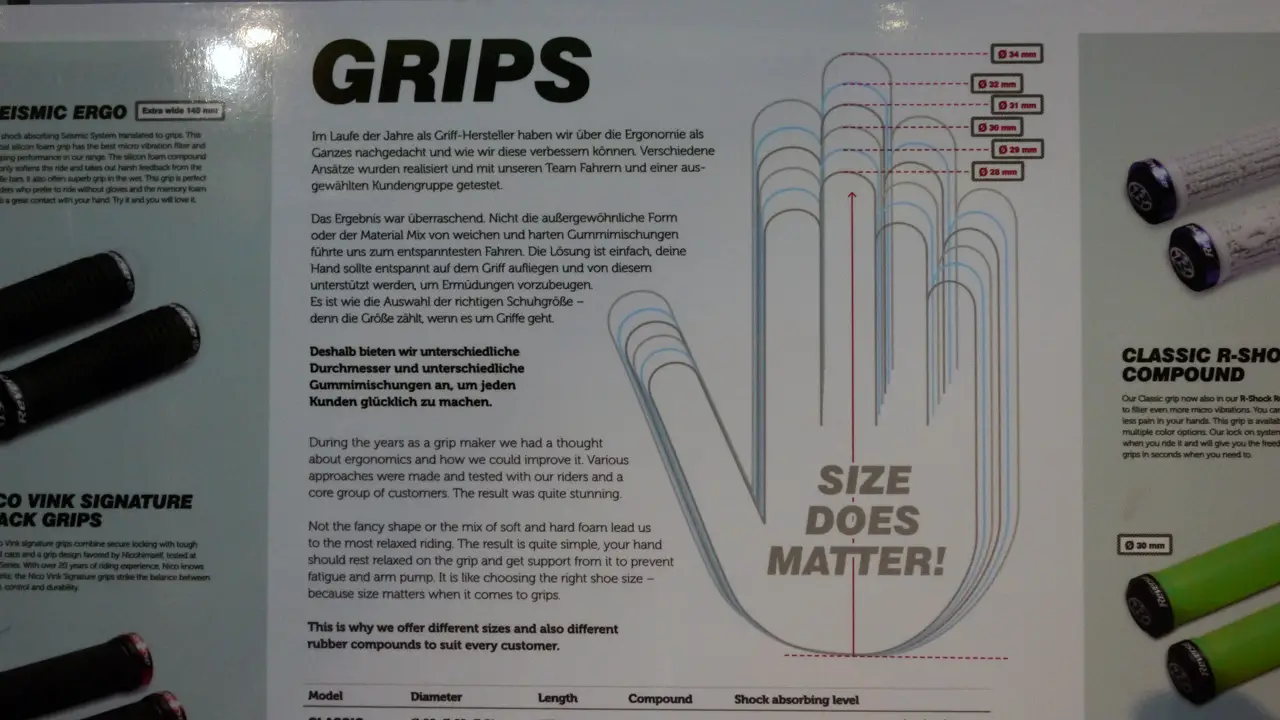

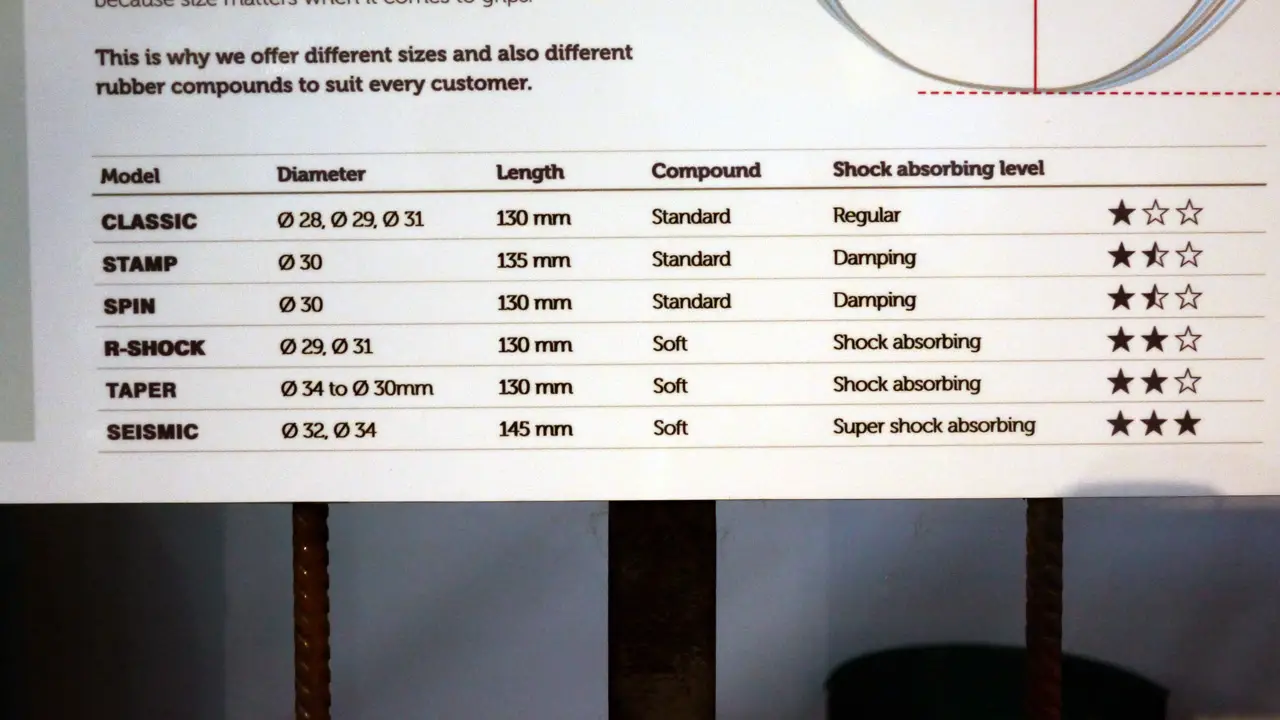

First of all, they had a very straightforward take on grip sizing, and based on that a range of grips to suit almost all hands. The basic idea according to them is that, when gripping a grip, the tip of your longest finger should be just, or nearly, brushing your palm. They say this is one of the factors in avoiding arm pump, and had a sizing chart along with a couple of grip demo stations for people to try it out on.

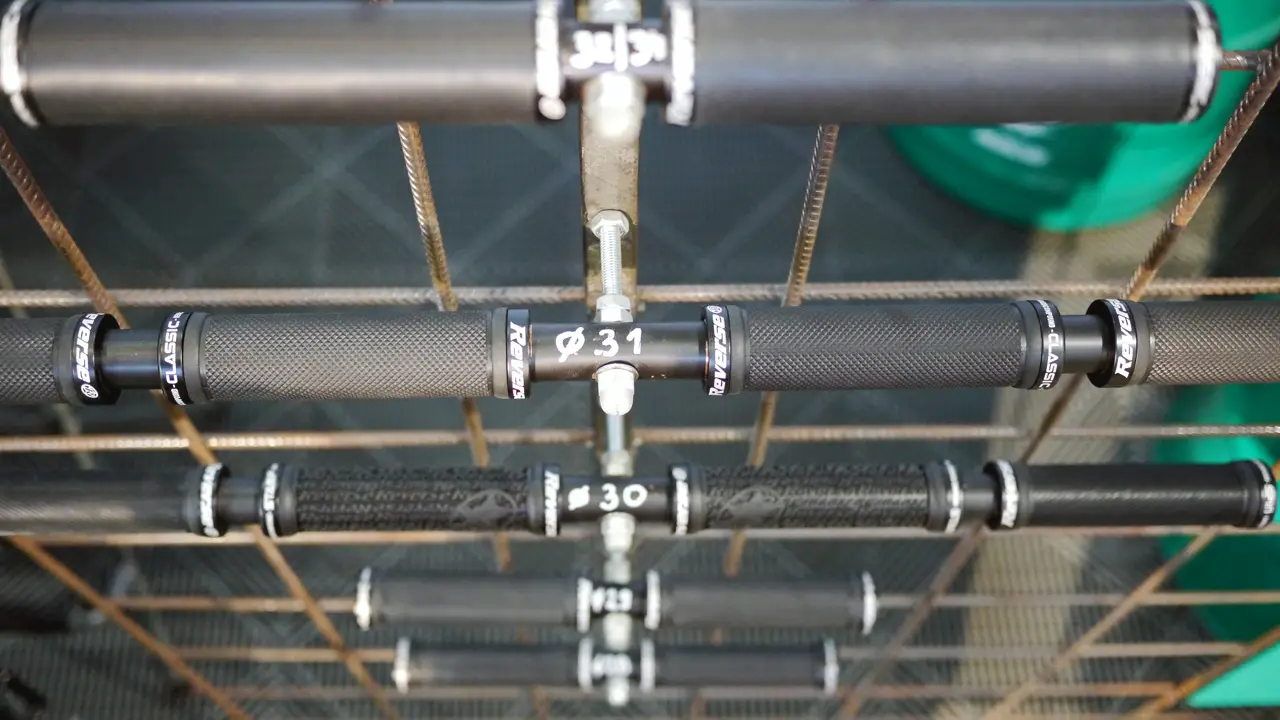

Experience and varied preferences around the office tell us that’s not the one single factor in grip comfort, but it’s an interesting approach and, after a quick discussion and a squeeze of some grips downstairs in the workshop, it roughly correlates to the preferences we’ve all developed. Reverse Components had a monkeybars style rack on their stand to try various grip diameters out on, and a more space saving box full of single grips with their diameters clearly marked on the end caps.

Now, here’s that ebike specific pedal:

Why is this a thing? Well. In Germany and France, there’s now a certification standard for ebike components, and that’s why Reverse Components are making ebike specific finishing kit like pedals and handlebars. It might not be as important to you as a customer, but if someone buys an ebike from a dealer, asks them to swap out a component, and it then breaks, fitting ebike certified components reduces the dealer’s liability in the event of an accident.

There’s a school of thought that the kind of burly kit people refer to as “over-engineered” is actually under-engineered. That’s because it can be relatively easy to make something that’s heavier or tougher than it needs to be, but a well engineered piece of equipment uses no more material than it needs in order to do the job for its projected service life. Do enough engineering work (which nowadays tends to mean CAD and spreadsheets) and you can bring that down to the absolute minimum necessary material to function and withstand particular tests. For bike bits, those tests are mostly built around the stresses a pushbike and rider will produce (admittedly in most cases that’ll also have a wide safety margin on top, because it’s no use having the absolute lightest components possible if you’re going to bend them every second ride). Ebikes weigh more than standard bikes and put a lot of components under slightly higher strains, hence people making new certification schemes for them.

Make of all that what you will, but Reverse Components have spotted the need and are one of the few companies filling it. As well as grips and ebike components, they had a few other things you can check out below, and you can see all of this over on the Reverse Components website.

Are you sure its not a load of DH kit left over being rebranded E bike specific 🙂