Home › Forums › Chat Forum › Any woodworking experts got any tips for Elf?

- This topic has 195 replies, 37 voices, and was last updated 13 years ago by Elfinsafety.

-

Any woodworking experts got any tips for Elf?

-

ElfinsafetyFree MemberPosted 13 years ago

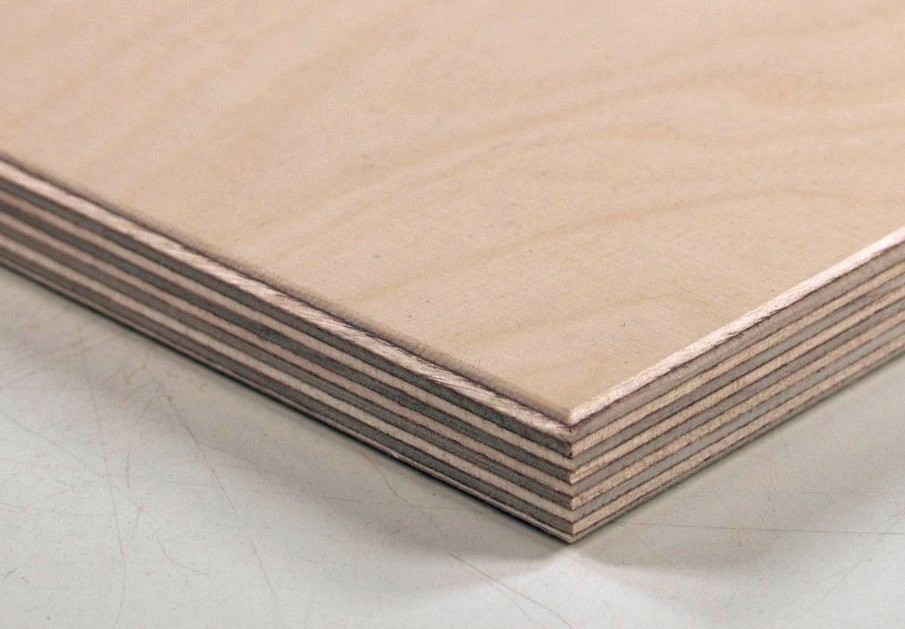

Right. I’m currently working on some Top Secret designs what involve using layers of plywood then sanding down to get that beautiful stripey effect, sort of like this only not quite as complex:

More along these lines really:

I got an offcut of 13mm ply for £2 and have made some prototypes. Currently sanding off the first one and giving it an rounded edge look. Really quite therapuetic actually. Sawdust everywhere mind…

So, are there any tips on particular types of plywood to use? Any elfinsafety issues with the dust a la MDF? What stuffs are best for such applications? All a fun learning curve…

And what about finishing? What sort of varnish? Oil? How to achieve a beautiful smooth finish?

Any tips grapefruit appreciated, thanks. 🙂

kayak23Full MemberPosted 13 years agoBirch ply is the best and consequently the most expensive. With cheaper plywoods you tend to get more internal voids between the laminations.

Birch ply has a beautiful edge to it when polished.As with anywoodworking, you want to do it in a ventilated area with a decent dustmask, do not skimp on this. You want one with a ‘P2’ rating.

You can finish it how you like really but avoid heavy build varnishes particularly if the item is small and intricate. Sand bacl between coats. I am much more into more natural looking matt finishes. Danish oil is a lovely and durable finish. Apply it, and then apply a small amount of wax and buff to a good shine.

With plywood, I’d be careful with wax. Any holes in the ply edges will fill with wax and look duff…

Are you turning the ply on a lathe or purely hand-shaping?chickenmanFull MemberPosted 13 years agoNormal Far Eastern (exterior ply) has a very pithy grain structure and doesn’t sand well across the grain. Birch Ply is perfect for the job and smells great when you machine it. Often used for shop fitting where a light coloured timber is required and looks fine with no fore-edges on it (very time consuming doing these!) Normally sold by sheet material wholesalers only, but some independent timber yards may have the odd sheet or two. Expect to pay 65 quid for an 8 by 4 though!!

ElfinsafetyFree MemberPosted 13 years agoI thought you knew everything???

No I don’t that’s why I’m asking for advice, innit? Gah… 🙄

Kayak; some great advice there, thanks. I’ve only just started using ply, but hope to progress to more complex and ambitious projects. Probbly going to be looking at professional manufacture of component parts then hand assembly and finishing.

Oh, and any tips for glues to stick sheets together? I’m using dowel ‘pins’ to lock layers in place, but standard wood glue ok?

Purely hand shaping. Any tips on a small lectric hand sander? Would be useful to have something that fits in the hand. Just for when I need to sand back quite a bit, saves time. Fine finishing done with just a bit of paper and small piece of wood block. Any tips on good sandpapers? Or just owt easily available?

Like the oil/wax idea. I’ll look into that. Blimus; some of the varnishes and oils etc aren’t half spensive eh? 😮

Expect to pay 65 quid for an 8 by 4 though!!

I am becoming aware that materials in relatively small quantities are quite expensive! However, from a sheet that size, I could produce a fair number of items and the accumulated finished item unit cost would mean the original materials cost is a relatively small fraction. Quality of materials used is paramount however.

Anyone got any examples of their own work? Different stages of the process?

kayak23Full MemberPosted 13 years agoAny tips on a small lectric hand sander?

You can spend a lot, but to be fair, I got a £25 palm-sander from B&Q and its great and if it breaks, back it goes.

Any tips on good sandpapers?

Abranet is great but a little pricier. It doesn’t have a sold cloth back as most papers do so doesn’t clog too quickly and lasts much longer. I’d avoid the packs you get in DIY shops as for what you get its dead expensive. If you plan to do lots of sanding then you may be better off getting a roll of decent stuff form somewhere like Axminster power tool centre.

Also, for rough shaping depending on what it is, you may be better off with Surform tools and/or a dremel or angle grinder with a coarse abrasive disc. Get a cheap angle-grinder and you’ll save a lot of work rough shaping. yossarianFree MemberPosted 13 years ago

yossarianFree MemberPosted 13 years agoAs with anywoodworking, you want to do it in a ventilated area with a decent dustmask, do not skimp on this. You want one with a ‘P2’ rating.

Plus one for this. Carcinogenic innit.

IanMunroFree MemberPosted 13 years agoI know nuffink about woodwork, but a bloke down the pub makes these, which are rather nice.

Wasted on a chickens though.wwaswasFull MemberPosted 13 years agoI’ve got one of these;

http://www.axminster.co.uk/bosch-bosch-pmf-180e-all-rounder–240v-prod656314/%5B/url%5D

let’s you do cutting and sanding, not a bad bit of kit – been great on some windows I had to cut bits out the frame on.

hilldodgerFree MemberPosted 13 years agomogrim – Member

I thought you knew everything???Nothing useful though 😆

Serious tho’

you’ll need to glue the layers carefully, and use some sort of clamp to bind it all down – what can happen when you come to stain/oil is that as you’re staining the cut faces rather than the finished surfaces you may cause swelling of the layers and worst case, delaminating or warping.Personally I’d follow up sanding with a good buffing using a floppy mop, then finish with beeswax as that tends to ‘sit on’ rather than ‘soak in’

khaniFree MemberPosted 13 years agoNot good with wood myself but the late FIL used to make guitars, lutes and wooden da Vinci clocks, all the movement was made of wood as well, cogs n everything,

I’ll post a pic when I get home latermaccruiskeenFull MemberPosted 13 years agoIf you are looking at small production runs chat up a friendly signmaking business and get them Cnc route stuff for you in quite periods. That way you get reliable repeats of your blanks before you hand finish them. Get full sheets of ply delivered direct to them and that way you’re not lumbered with full sheets, or the dust and offcuts. Or…… Learn how to work with routers and templates and get a template Cnc’d and route blanks from that – serious quantities of dust this way though. As above birch ply is where it’s at, there are varying grades though, make it clear that you want boards without voids because some grades can still be quite gappy.

If you buy a sander look at the shape of the dust extraction port, most come with a filter that is useless, what you want to do is plug a Hoover into it, so a round port will allow you to bodge a connection. I use cheap royobi random orbit sanders for the shape of their dust port alone- and they do the job just fine

DezBFree MemberPosted 13 years agoIf you want a electric sander for nothing, I have a spare (or 2 – a builder left them behind).

This sort of thing

nickjbFree MemberPosted 13 years ago

nickjbFree MemberPosted 13 years agoBirch ply is the best. I make loads of stuff out of it. Sometimes with the wood on show, sometimes just as internal structure.

Here’s a bit being shaped, but not by hand

Here’s a interactive pulley exhibit with a birch ply table:

interactive exhibits – pulley table. This is finished with sanding sealer.Find someone who CNCs it and they will have loads of offcuts for messing around with. Might be useful if you do decide to go into production, too. I know a few round here but none in that London.

If you want to stick up a few layers then wood glue is fine but you need to clamp it up tight or vac bag it. A bit of weight is not enough.

maccruiskeenFull MemberPosted 13 years agoAlso, although birch is typically stocked by more specialist outlets, sometimes b&q have it on the shelf, and at a pretty sensible price. It’s heavy stuff, much weightier standard hardwood ply. They only sell it in full 8×4 sheets but you can get it cut into transportable sizes for free.

alpinFree MemberPosted 13 years ago^^^wow!

elfin…. have a look at Glulam timber beams.

i had a few lumps of it at home after someone got their measurements wrong and i had to lop a bit off two massive (6m) glulam joist bearers.

looks like a massive, 18×8″, lump of laminate.. well, that is exactly what it is.

some do vary in layer thickness. heavy stuff, too.

grantwayFree MemberPosted 13 years agoOK worked on the proto type bags Angelina Jolie used in Tomb Raider

with Victori bags, these was two bags one had the gadgets that fell

out the bottom and another held other gadgets But in the film it looked

like one bag.For me to advise you need to let me know what your trying to achieve

IE is it to be turned etc

I don’t want you loosing a finger or two!Regarding Dust be very carful you’ll find the most toxic dust in cheap

ply wood so a EN 149 rated mask is only to be used.

I have plenty of those you can have for Free !grantwayFree MemberPosted 13 years agoIn saying the above what your trying to active you’ll need a 4 or 5 axis CNC router

off the top of my head I thinks there is a place near Dalstoni can put you in contact with contracted spray finishing company in Tottenham

ElfinsafetyFree MemberPosted 13 years agoOoh forgot all about this thread, and I started it! What a tit. 😳

Khani; I actually need that clock. Give to me it please.

Amazing…

Some great tips and advice here, thanks loads. Really helpful. 🙂

Dezinald; once again that’s extremely kind of you; actually they could be replacments for some of the gear what got stolen from the community garden. Some scumbaygs nicked our generator and some power tools. 🙁 Any thing like that would be most gratefully received.

I spoke to someone last night who might be able to put me in touch with a few contacts for manufacturing. Should be able to find someone here in That London though. Hopefully this recession will mean they’re not too spensive….

Only stuff what will be done here at home will be prototypes and some finishing. So small scale stuff, not too much dust and that. Appreciate the info re masks, can get loads off a mate who works in a science lab. I won’t be working with the stuff all the time, so less exposure and risk.

With ply, someone mentioned different grades. What’s the best stuff? And any tips on how to look for decent stuff/defects etc?

khaniFree MemberPosted 13 years agoHe made four, two here and two ooop norf, if I gave one away I truly believe the mrs would stab my face up…

An I’m ugly enough…soz. 🙁grantwayFree MemberPosted 13 years agoil have to do some checking tomorrow fella

was a Two year back of knowing of it.

Pretty good prices too.Regarding tooling you best use Diamond Tipped cutters as the resin in the glue will kill

the TCT type cutter.

Best place to buy them is North London Saws there near Waltham Abbey they will make any shape

you require left or right handed.I use

William T Eden in Rochester for all my panel products including Birch Ply which I use for drawers

fit and forget material.

There is Blumson in Ripple Road Barking but sell little panel products.

Also you have James Latham near Purfleet But i don’t use them they let me downElfinsafetyFree MemberPosted 13 years agoNice one Grantway.

Some lovely stuff made out of plywood.

Look, beautiful:

You’d have trouble with this one though I reckon, Khani…

…it’s slatted. 😐

ernie_lynchFree MemberPosted 13 years agoSome lovely stuff made out of plywood.

Look, beautiful:

😆

tailsFree MemberPosted 13 years agoElfin you might have to spell out what your doing a bit more I’m sure it can’t be that top secret.

Anyway http://cutlasercut.com/ may be able to cut you out pieces to minimise the sanding. Alternatively the RCA certainly have the tools you may be able to pay to use them, the same goes for Ravensbourn and Bucks out in High Wycombe.

Ask local exhibition design companies they might have a CNC or will know someone who will. If the item is more of a cylinder then a CNC lathe or a man in his shed will help. You can make a sort of lathe with a power drill in a vice, I have used this for model making. Actually even Ercol in Princess Risborough do private work.

As above BIRCH PLY is the the good stuff, ply can be veneered with cherry, walnut etc at cost. Not much use to you I think.

I’d be using wax or sanding sealer as it’s easy and not to messy.

Anyway got to go play footy will try add more later.

chickenmanFull MemberPosted 13 years agoThe strength limitations of glue-lamming small pieces together is perfectly illustrated in the new bulding at the Botanical gardens in Edinburgh: the spiral staircase up to the upper level was meant to be strong enough with just the glue-lamm spiral balustrade and handrail…it now hangs off a couple of threaded bars slung over the roof beams!

A bit like James May trying to make beams from Lego really..esselgruntfuttockFree MemberPosted 13 years agoI’m no expert but these lot are…http://www.john-boddy-timber.ltd.uk/

You could always fone em, or, come aall the way up her to see them, about .755 of a mile from me. (bring a coat though, might be a bit chilly for a suvvener) 😉

ElfinsafetyFree MemberPosted 13 years agoWhy you laugh Ernie? You do not know beautiful things . 🙁

I’m sure it can’t be that top secret.

It is actually top secret.

All shall be revealed in the Fullness of Time….

ElfinsafetyFree MemberPosted 13 years agoNo, YOU look….

Best not say it really. Don’t want to descend to your level. 😐

Why can’t you just be nice and helpful like everyone else on this thread? Why you have to be so nasty? 🙁

Grantway; I thought that was who you were on about. Simple, stylish gear but overpriced imo. Might go and ask them about getting small parts done actually.

grantwayFree MemberPosted 13 years agoNa these was on Kingsland Road

Think those guys only have a three axis cnc machine you can tell by there designs.

fourth axis costs an arm and a leg or twocouldashouldawouldaFree MemberPosted 13 years agoI’m far from an expert – but ime – when you try and sand down b&q type ply (external £27 a sheet) it turns to woolly fluffy nappy stuffing.

I guess all the above was done with quality stuff – probably not from b&q!

tangFree MemberPosted 13 years agoMy Dad(who is a potter) was telling me about someone he met at a show recently who was making something with that process (cant remember what). He went to China and found some factory who does it for him for pence and is now coining it. My Dad being a start to finish craftsman (of some fame within ceramic circles) was not impressed.

swiss01Free MemberPosted 13 years agoi imagine someone in that london must have something made of ply by tony cragg. i would travel some distance to see that again

DobboFull MemberPosted 13 years agoGreat thread, given me loads of ideas of things to make. I’ve got into woodworking recently, I think could recite the Axminster catalogue off by heart.

I like the finish on the pulley table nickjb, is that using finishes like these (last 3 items) Chestnut Finishes.

The topic ‘Any woodworking experts got any tips for Elf?’ is closed to new replies.