- This topic has 195 replies, 37 voices, and was last updated 12 years ago by Elfinsafety.

-

Any woodworking experts got any tips for Elf?

-

stumpy01Full MemberPosted 12 years ago

Interesting thread this…….

I have always liked the idea of working with wood & am going to an open day at a local college next week to see what evening classes they do.

I know they do one on carpentry, but I don’t know if that is going to be more to do with joinery stuff like how to hang a door etc. rather than tinkering with wood in an artistic sense.I’ll see what they have to offer anyway. If there is nothing suitable, then I’ll see what they have in terms of photography instead.

DobboFull MemberPosted 12 years agoI’ve got some of these dust maks with the valve, if the valve operates I assume it’s a tight fit, although probably not fully air tight!

I also have a Sealy vacuum cleaner that I connect to my table saw and router, impressive to see how much it collects, it’s got a cleanable filter as well.

nickhartFree MemberPosted 12 years agoi use stacks of birch faced ply at work (d&t teacher at a local school) and it’s lovely to use. get some sort of extraction unit. at home when i’m turning wood i use a good quality face mask and prop a hoover tube over where the waste comes from. works quite well.

we use sanding sealer at work, thinned down to a watery consistency, glass paper smooth. then a THIN layer of sealer. glass paper again, then repeat. the thin layers allow it to dry well and save sanding stuff off too much.

looking at the benches pictured earlier they could be made (smaller) on the kit we have in school, either a laser cutter or a cnc router. build things in layers saves time and sanding and reduces waste material.

have fun.kayak23Full MemberPosted 12 years agoI have always liked the idea of working with wood & am going to an open day at a local college next week to see what evening classes they do.

I know they do one on carpentry, but I don’t know if that is going to be more to do with joinery stuff like how to hang a door etc. rather than tinkering with wood in an artistic sense.Cue the plug…

I am an instructor on furniture making courses (City & Guilds) in Leamington Spa, Warwickshire. Re-training is a great thing to do and we have students of all ages from 16 to 75 who get on really well.

Yes, a carpentry course will tend to be more on the joinery side, hanging doors, roofing, skirting etc etc. We focus purely on Craft-based furniture making and our students get an awful lot out of it.

We run evening classes for leisure or qualifications and full and part-time days too. We cover all aspects of furniture traditional and modern including laminating. We also have Photography departments, Jewellery, ceramics and glass. A very creative place to be.

I’d recommend doing an evening class for sure if thats your thing.

Warwickshire Collegestumpy01Full MemberPosted 12 years agokayak23 – Member

Cue the plug…I am an instructor on furniture making courses (City & Guilds) in Leamington Spa, Warwickshire. Re-training is a great thing to do and we have students of all ages from 16 to 75 who get on really well.

Yes, a carpentry course will tend to be more on the joinery side, hanging doors, roofing, skirting etc etc. We focus purely on Craft-based furniture making and our students get an awful lot out of it.

We run evening classes for leisure or qualifications and full and part-time days too. We cover all aspects of furniture traditional and modern including laminating. We also have Photography departments, Jewellery, ceramics and glass. A very creative place to be.

I’d recommend doing an evening class for sure if thats your thing.

If I was over that way, I’d definitely be getting in touch. To be honest, your info has given me an idea. I think i was only looking for ‘wood working’ and ‘carpentry’, but perhaps searching college websites for ‘furniture making’ might yield better results!

ElfinsafetyFree MemberPosted 12 years agoYeah, I’d like to do a woodworking class, yet sadly the only ones (reasonably) local to me are more to do with vocational training in joinery than craft/hobby type stuff. I’ve enquired about a few courses, but none of them involve stuff like inlay work or fine detailing and that, it’s more geared towards commercial production.

Lots of fantastic, really useful info here though. Once again STW comes up trumps. 😀

Glad it’s been enjoyable for others too. I’d still like to see examples of peoples’ own work though!

ernie_lynchFree MemberPosted 12 years agoI’d still like to see examples of peoples’ own work though!

Here’s a stool I made at work

Not quite finished mind – I’ve still got to sand it down.

stumpy01Full MemberPosted 12 years agoI think ernie has had even more training than I have.

Loving the rustic look you’ve achieve there, coupled with the practicality of a sturdy piece of furniture.How many seconds did that take to create?

khaniFree MemberPosted 12 years agoI

Madebodged my woodstore, for the free hardwood offcuts from the boys work

EDIT they actually skip it and pay someone to take it away 😯nickjbFree MemberPosted 12 years agothey actually skip it and pay someone to take it away

I need to know the location of that skip 🙂

ElfinsafetyFree MemberPosted 12 years agoKhani I actually need those offcuts give to me them please.

No seriously I need them. It’s for the good of Humanity.

I see Ernie is still being horrible and mean and nasty. 😥

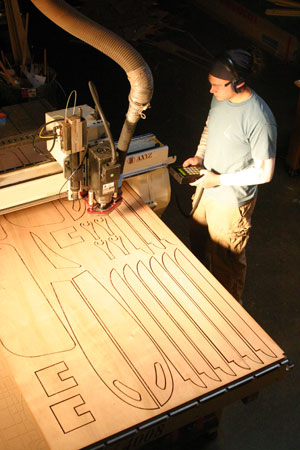

I’ve been Googling CNC machining, and it seems that’s the perfect answer for what I need actually. Will enable a sort of mass-production style operation.

Also it will be ideal for other designs I’ve got. But I’m not going to rush it, I’m going to start small and build up…

Right; anyone know any good CNC places in That London?

khaniFree MemberPosted 12 years agoI need to know the location of that skip

Shopfitters opposite billericay train station and down a bit……

There may be a queue…….stumpy01Full MemberPosted 12 years agoThat white 3 legged chair……looks well unstable. Are you actually meant to sit on it?

Elfin – check out this place: http://cncrouting.co.uk/

not near London, but have a gander at some of the projects…..!

cr500domFree MemberPosted 12 years agoBuild your own CNC Router…..

Its not difficult

Bloke here at work has one set up in his dads Garage for furniture making / Carving

Cost him about £1500 all in IIRC 😀http://buildyourcnc.com/default.aspx

Failing that any decent Signmakers will have a CNC router, just design what you want (Autocad/sketchup etc) and export as a DXF file and they can cut straight from that

HTH

Domstumpy01Full MemberPosted 12 years agocr500dom – Member

Build your own CNC Router…..

Its not difficult

Bloke here at work has one set up in his dads Garage for furniture making / Carving

Cost him about £1500 all in IIRChttp://buildyourcnc.com/default.aspx

Failing that any decent Signmakers will have a CNC router, just design what you want (Autocad/sketchup etc) and export as a DXF file and they can cut straight from that

HTH

DomWOW! The internet is a truly amazing place. I shall definitely be looking into that!!

ElfinsafetyFree MemberPosted 12 years agoAs well as Khani’s wood, I actually need a CNC machine now. 😐

More wonderful info. CNC 100% the way to go for my particular needs. In fact what can be achieved has made me reconsider some older design ideas I thought would be too difficult to realise.

Can CNC cutters use EPS files?

cr500domFree MemberPosted 12 years agoWhats EPS ? whats the system they are created in ?

Generally they work on g-code, but they can translate this from DXF / DWG files (Autocad 2d)

Step or IGES files (3d) can be used as well and I suspect you could actually create the form you need in Maya / 3dStudio Max and then export as an STL file which is generally layered cuts for rapid prototyping, if you played around with lowering the resolution to suit material thickness you could get some decent results that way if they can read STL ?

I`d see if Google sketchup can export as DXF and start there ;o)(I`ve not used it as I have Catia V5 / Solidworks/ Pro-Engineer)

HTH

DomElfinsafetyFree MemberPosted 12 years agoEPS = Encapsulated PostScript as used by Adobe Illustrator, Photoshop and that. Uses vector graphics.

2D, but tbh the stuff I need is just 2-axis anyway really.

kayak23Full MemberPosted 12 years agoIf I was over that way, I’d definitely be getting in touch. To be honest, your info has given me an idea. I think i was only looking for ‘wood working’ and ‘carpentry’, but perhaps searching college websites for ‘furniture making’ might yield better results!

Whereabouts are you? There is a few good places all over the country so I may be able to suggest somewhere.

speckledbobFree MemberPosted 12 years agoI’ve been working with some maple ply recently. It’s very expensive, I think around £250 a sheet. Imo its a bit bland although I haven’t put a finish on it yet. Birch gives far more dramatic stripes.

ElfinsafetyFree MemberPosted 12 years agoIt’s very expensive, I think around £250 a sheet

😯

I’m going to try some birch ply. I’ve had quite a fruitless day trying to find a local CNC firm, but there must be some around.

All this info has really helped me shape my ideas and plans a lot more, and I’ve got a much better idea of how to progress. I’ve gone from knowing very little indeed, to knowing very little. 😀

Bin doing a fair bit of research into things last few days, and it’s fascinating to see the amazing diversity of styles and applications. There’s stuff out there, ye Gods the prices??!!? 😯

Feeling a lot more encouraged about it now, and more confident in my own ideas. So thanks to all who’ve offered advice and tips.

Right: Does anyone know how to turn a design in Illustrator into something that could be used by a CNC place? Is it possible to turn an Illustrator image to a 3-D Sketchup file?

And is Sketchup Pro a good start for software for this kind of thing?

grantwayFree MemberPosted 12 years agospeckledbob – Member

I’ve been working with some maple ply recently. It’s very expensive, I think around £250 a sheet. Imo its a bit bland although I haven’t put a finish on it yet. Birch gives far more dramatic stripes.LOL what you have had done is had the ply sheet veneered in Maple.

The Veneer would be either in Crown cut or Quarter cut veneer or the cheaper cut of veneer we call Stripe

you have paid way over cost has you can buy pre veneered board a lot cheaper.Effin could not get out to find out about the CNC company has in bed with Bronchitis

ElfinsafetyFree MemberPosted 12 years agoAh what Grantway I need you fit and well mate! 😮

About a week ago, I had an idea then got all excited and went out to get stuffs.

Now, I’m sitting here bewildered by the sheer magnitude of choices and different processes. People say ‘birch ply’ but then there’s different grades, different sources, Lord above.

So what’s this Danish oil and beeswax thing then? How does that work?

grantwayFree MemberPosted 12 years agoEffin your rather lost give me till the weekend and il go through things

over a coffee with you.

I can’t bare it I can give you commercial advice and numbers and how too

up to you.

Going to bed now.nickjbFree MemberPosted 12 years agoYou should be able to get something useful out of illustrator. I haven’t got illustrator in front of me but IIRC you can export as a DXF, it might need a plug-in. Adjust the setting for the earliest DXF version as most CNC machines are pretty basic

Sketch-up is OK. There are quite a few plug-ins for importing and exporting but you might need the pro version. Its still a bit sketchy for my tastes rather than proper 3D cad but you might get on with it.

Draftsight might be a better option to create 2D shapes for cutting. If you get a DXF out of illustrator I’d still download something like this to check it or modify it.

speckledbobFree MemberPosted 12 years agograntway

The client specificaly asked for a maple core ply for a project I am involved with. I’m simply saying other types of timber board are available but at a cost.

grantwayFree MemberPosted 12 years agospeckledbob – Member

grantwayThe client specificaly asked for a maple core ply for a project I am involved with. I’m simply saying other types of timber board are available but at a cost.

Sorry fella but yep that is true

DobboFull MemberPosted 12 years agoHow many of these pieces are you looking at making then elfin, couldn’t you make a prototype by hand? What did you say it is you’re making again? 😉

I’m loving the effects that can be got from ply, the topo table is amazing, I’d have the topo side up with glass over it. I keep thinking of things I’d like to make from it but I don’t think I have the skills yet, having an image in your minds eye and getting it made can be very different things, I’m not the most patient either to put it mildly. I like to finish everything in a day or i dont sleep at night 😐

maccruiskeenFull MemberPosted 12 years ago2D, but tbh the stuff I need is just 2-axis anyway really.

If its just 2d cut outs you’re getting cut then a sign shop will be all you need, the one who does work for me works straight from Illustrator files – their client base will be more graphic-designery so thats the kind of file they’ll more used to receiving and working with.

People say ‘birch ply’ but then there’s different grades, different sources, Lord above

The grades typically relate to the face surfaces the best being A, then B then C… Sometimes you’ll have one good side, so A on one side B on the other etc.

An ‘A’ will be the face ply being as near as dammit flawless, a B will have any flaws neatly and pretty much invisibly patched, C is getting a bit more honest looking. However for what you seem to be doing the faces don’t matter much, so you need to ask the supplier for whichever board has the least internal voids

kayak23Full MemberPosted 12 years agoSo what’s this Danish oil and beeswax thing then? How does that work?

Danish oil and wax as finishes work in different ways. Wax essentially sits on top of the wood, oil gets drawn in. Both are moderately durable but you wouldn’t want to put your cup of hot tea down on them.

Danish oil is applied by thinning the first coat with some white spirit which makes it easier for the wood to suck in that oily goodness. Subsequent coats can be put on ‘neat’ though some prefer to thin subsequent coats in diminishing ratios of oil to spirit.

Danish oil gives a lovely matt sheen when the coats are built up and it is burnished(rubbed hard to build up friction-heat)

Because of the dull sheen it leaves, some like to add some wax over the top to bring more of a shine to it and to add a further layer of protection. Something like ‘Black Bison Wax’ (don’t worry, its not made out of bisons) is a lovely wax and will add to the quality of the finish although waxes are notoriously hard to apply really well with a very even sheen.Also, I’d avoid waxes on intricate pieces with corners as its all too easy to get a build up of wax in the corners.

Finish really comes down to final useage.

Something like a dining table wants a durable finish, pre-catalysed lacquer or something is ideal(even this can be applied matt and then have wax over the top for a more natural-looking finish, as lacquers often look ‘plasticky’ if too high-build/thick)If your item is a decorative item such as a small sculpture, then the finish is going to be more of an aesthetic consideration than a practical one. Where I’ve made small woodturned items i’ve pretty much just wanged a bit of Danish oil on them and left them at that.

For large numbers of items which you are alluding to, I’d say you’d be better off approaching someone who’ll do it for you, in a finishing shop.

kayak23Full MemberPosted 12 years agoHave you seen the guide to birch plywood grades on James Lathams site?

stumpy01Full MemberPosted 12 years agokayak23 – Member

Whereabouts are you? There is a few good places all over the country so I may be able to suggest somewhere.

Thanks. I am near Peterborough, but work in Letchworth. So, I was thinking some kind of evening course near Peterborough or somewhere lik Bedford, Huntingdon etc. which are pretty much on the way home.

King-ocelotFree MemberPosted 12 years agoA fantastic thread. I’ve been wanting to do an evening class too, but the one round here is more Joinery based.

I’ve just built my MIL to be a dovecote out of the timber from my old bed and a few bits I found. I made a dovecote before for my parents (my dads a carpenter) and he gave me lots of pointers. I’ve got an old canvas wardrobe in my shed I’m going to turn the frame into a bird table for myself. Id upload photos but my internets broken and I’m on my phone with no 3G 🙁 if I remember I will do it over the weekend.

The clocks posted are amazing, really impressive and intriguing, No doubt with huge sentimental value too.

cr500domFree MemberPosted 12 years agoElfinsafety – Member

EPS = Encapsulated PostScript as used by Adobe Illustrator, Photoshop and that. Uses vector graphics.2D, but tbh the stuff I need is just 2-axis anyway really.

(pedant)its only 2D until you need to cut it 😀 (/pedant)

According to my other half who is also a felt tip fairy and has a Sign company supplying the trade, they can take Adobe Illustrator files and cut on their CNC Router and Laser cutter.

whether thats uses a conversion in some other software or not I couldnt tell you, but its possible within the sign trade at leastWe’re in Norfolk if that helps, not that far from that there London 8)

The topic ‘Any woodworking experts got any tips for Elf?’ is closed to new replies.