Home › Forums › Bike Forum › Spoke nipple er.. penetration

- This topic has 4 replies, 3 voices, and was last updated 4 years ago by alexnharvey.

-

Spoke nipple er.. penetration

-

BearBackFree MemberPosted 4 years ago

Just rebuilt a set of first generation Spline1 wheels with e13 TRS+ rims and 2nd guessing my resulting spoke/nipple penetration

DT’s erd was 565mm with DT including the phr washers.

e13’s spec (and tech support) says 561mm.. so adding Sapim MG washers (+2mm ea) would on paper match the erd and be good to swap the rim over with no spoke length worries.

The E13 rim is quite clearly lower profile than the DT rim though and I measure the erd at 566mm using basic 2 spoke methods.

Of course I didn’t measure this difference until I’d laced and tensioned the rear wheel and noticed that the spokes weren’t coming quite as high into the alloy prolock squorx nipple as I expected or have seen with my previous build.

For the front I used Sapim HM’s instead. less strength than the MG washer but I need washers according to E13 and these HM’s save 1mm each over MG.

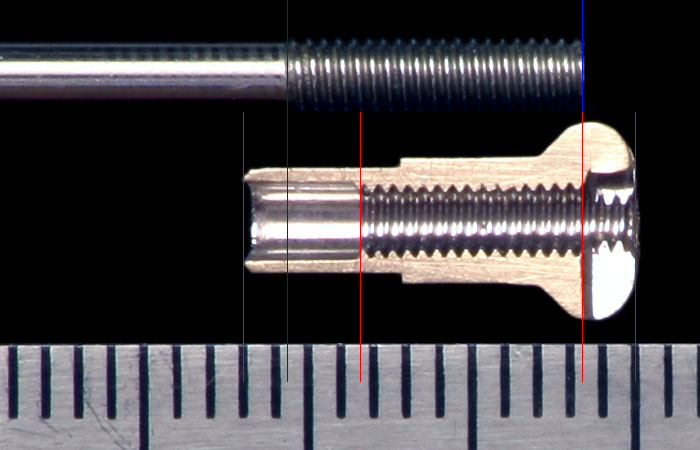

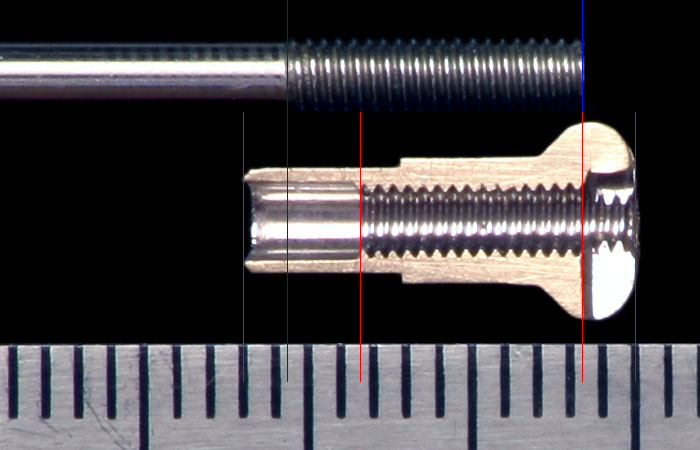

Front wheel has mostly better penetration.. still not as much as I’d like and I don’t really want to re-lace the rear if its going to be ok.Id say with the ‘worst case’ nipples I’m somewhere between these 2 pictures.

I’m definitely at least a turn or two past no-go at the nipple seat but not quite as far as the ‘ideal’

Whilst this is a kid build, he’s still hitting transition on aline, fade to black etc on his current bike and will only be going bigger next year.. no dental coverage means I’d prefer to avoid the wheels catching fire.

Comparing this to a regular nipple, it’d be the end of the spoke approaching the bottom of the nipple driver slot (probably like the top pic of the 3 pack at the bottom)Am I safe where I am assuming i’m anything past no-go?

walleaterFull MemberPosted 4 years ago

walleaterFull MemberPosted 4 years ago‘Alloy’ nipples have a habit of breaking at the heads if the spokes are too short. E13 nipple washers are also the fairly ‘normal’ looking type, i.e. only maybe 0.5mm thick? I’ve not put a caliper on one but I’ve not bothered taking into account the thickness of them when calculating spoke lengths. But if the calculation puts me in between spoke sizes I’ll go with the longer ones.

On that bottom photo, I’d be happy with option 2 first, then 3 and not so happy with option 1. I’d say it’d be OK with brass nipples but potentially not so with alloy in the long term. The wheel won’t just collapse though. Might just ping a nipple or two in the longer term due to fatigue.

cynic-alFree MemberPosted 4 years agoI confess I didn’t read all the OP

Every single one of those pics shows sufficient thread engagement IME.

and I don’t really want to re-lace the rear if its going to be ok.

Wait and see how it goes then?

alexnharveyFree MemberPosted 4 years agoThose pictures indeed all show sufficient engagement.

If the spoke end in the first picture was a mm lower in the nipple it would be insufficient. You can see that the threads would also have just barely disappeared into the nipples if that is the case.

The topic ‘Spoke nipple er.. penetration’ is closed to new replies.