Home › Forums › Chat Forum › Solar water thermal panels: The installation… (w pics)

- This topic has 159 replies, 41 voices, and was last updated 13 years ago by miketually.

-

Solar water thermal panels: The installation… (w pics)

-

EdukatorFree MemberPosted 13 years ago

Thanks for that, I’ll have to read it half a dozen times and do some sums to see how it compares with my experience. I’ve currently got about 10 steres (10m3 cut and stacked) of pine, cherry, oak, birch, beech and stuff I’d have to look up the English word for. All chopped and under cover drying. If I had to buy it it would be about 35e/stere in big logs of the truck and 60e chopped for a Jotul. Graham’s prices therefore seem very reasoanable.

SurroundedByZulusFree MemberPosted 13 years agoDid they ever develop combined solar thermal and solar PV collectors?

EdukatorFree MemberPosted 13 years agoI’ve now ahd time to do my sums and my 5000kWh from three stères of dry soft wood corresponds exactly to graham’s 5kw/kg.

What’s confusing me is how to convert m3 of gas into kWh. Should I be using the equivalence given on the gas bill or correcting by 50% for the efficiency of the old boiler (as I have been doing)? What do you reckon 230m3 of gas is in kWh?

#decides to sleep on it#

StonerFree MemberPosted 13 years agoIm not that sure its easy to get to 5kWh/Kg for wood without kiln drying or very very long storage.

My pellets are rated 5kWh/Kg and they are “manufactured” and kiln dried to <5%

StonerFree MemberPosted 13 years agoThis site says 1m2 = 11kWh

http://www.energylinx.co.uk/gas_meter_conversion.html

And when I do my calcs I usually correct for efficiency losses. So my biomass boiler is 89% efficient on pellets and 82% when I use logs.

EdukatorFree MemberPosted 13 years agoYour site confirms what’s on my bill. If I correct for efficiency:

Gas: 2500 kWh at 50% = 1250kWh

Wood: 5000kWh at 80% = 4000kWh

The wood is chopped small enough for a Jotul and dries two years or more in clear-plastic-roofed stores before being moved under a covered terrace where it gets baked by the southern sun before burning. Edit: even if I paid for the wood it would still be cheaper than the gas – gas is expensive in France. About 300e for the gas including standing charges and 200e for the wood.

I was aware that the house is cosier since we started using wood and that we heat the whole house rather than parts of it but that’s still a lot more wood energy than gas.

StonerFree MemberPosted 13 years agohow come your boiler is only 50% effiicient?

That’s nuts.Modern combis are getting towards 95% efficiency.

You should look at the pay back on replacing the boiler based on efficiently gains.EdukatorFree MemberPosted 13 years agoIt was a

1960S1970s combi boiler. It’s gone to the great recycling plant in the sky (minus the pump I kept to cycle the water heated by the wood burner) and I’ve had the gas cut off.Edit: the consumption figures in my last post are for the last year we used gas (but no wood) and the following year when we used only wood.

StonerFree MemberPosted 13 years agoahhhhh.

SO what do you use for “on call” heat? Immersion or light a fire?

StonerFree MemberPosted 13 years agoHAHA! It only bloody works!

73 solder joints, 17 compression fittings and just one leak, in one of the easier places to fix, at the tank connector! Miraculously no leaks outside with my first godawful soldering.

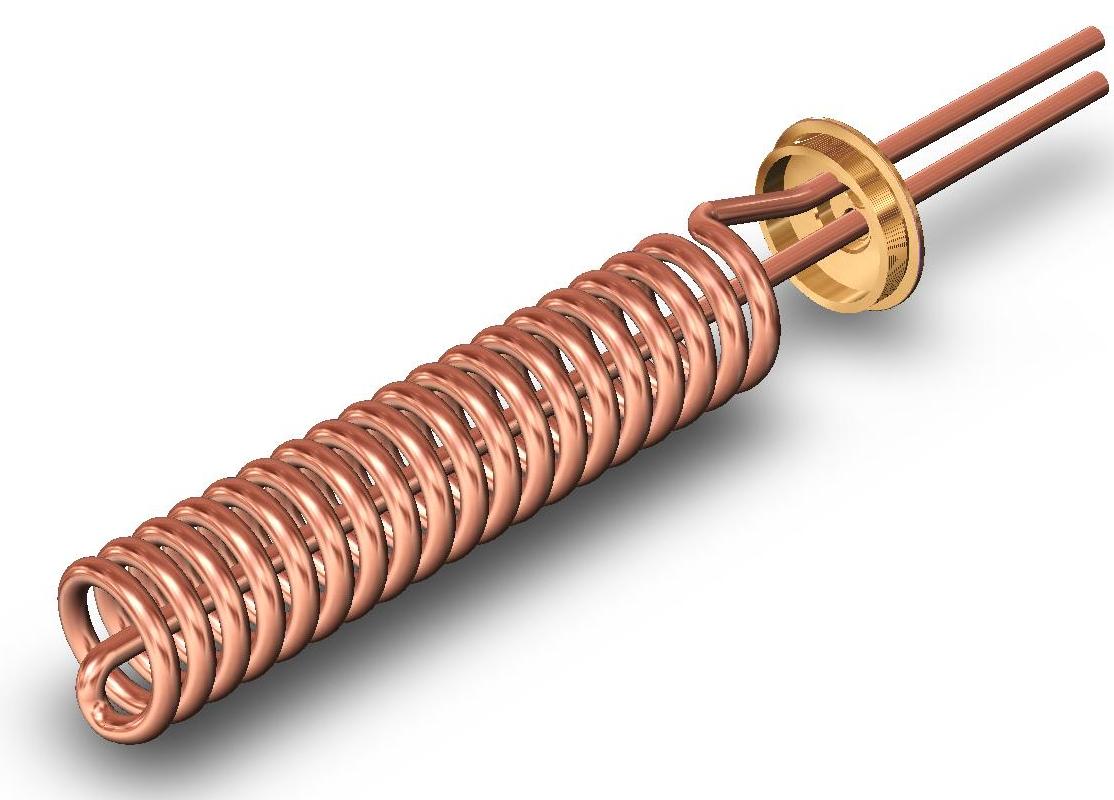

feed from bottom of thermal store coil, through check valve (hot run) and drain cock and pump (bottom run), then round the back of the boiler

Copper filler loop and header expansion pipe up to the header tank (flexy one is the boiler filler loop) and past the two bleeders to the DN20 hose outside

Header tank with leaky connector. Expansion pipe goes over the top and drops back in.

Wired the pump to the mains to run it around.

There’s about 27 litres in the system below the tank. A fair bit.

Now to partially drain, fix that leak, then load with glycol mix. Then I can wire up the controller and temperature units that arrived in the post this morning.

muppetWranglerFree MemberPosted 13 years agoGood effort. 1 leaky connection out of all that lot is pretty good going. Keep us up to date with how it works.

I like the more adventurous DIY threads.

EdukatorFree MemberPosted 13 years agoFlax and plumbers putty for tank joints.

I had a think about your system when out on the bike this morning and I reckon you weak point is that the system runs at such a high temperature. In Decemeber you’ll have trouble getting the primary solar circuit up to the temperature of the thermal store let alone above it. Even vacuum pipes struggle to reach 65°C in winter especially with the losses you’ll have on the long pipe runs. The sun comes out, it takes ages to get the panels up to temperature. Once they are up to temperature the pump starts but stops as soon as the cold water in the supply/return circuit reaches the sensor. In the time it takes for the panels to reach 65°C again the water in the pipe runs has cooled down. After a cold night in December it’s midday (11:00 am UK) before my solar panel starts circulating with a tank at less than 20°C.

Question answer: When the water from the solar water heater isn’t hot enough for a shower I feed into a conventional 50l tank with an immersion heater. A guestimate is that the immersion heater accounts for about 350kWh of our yearly electricity consumption.

StonerFree MemberPosted 13 years agoIn Decemeber you’ll have trouble getting the primary solar circuit up to the temperature of the thermal store let alone above it.

stratification my dear Watson!

The thermal store can be 85 at the top and can still be c.20deg at the bottom.

In winter the solar panels are there to “pre heat” the lower temp water when sufficient insolation is available (I can of course change the hysteresis of the controller for winter behaviour if I want), through natural straification, the energy can rise to the top of the thermal store (2m above) at which point the DHW coil is going through the store.

flax etc. nah. Silcon bodging!

coffeekingFree MemberPosted 13 years agoI may have missed this but is your boiler happy with a pre-heated supply of water or are you running a separated system?

StonerFree MemberPosted 13 years agock – think of it a bit like this, but rather than the water in the tank going straight to taps there is another coil near the top that indirectly heats DHW.

hang on, Ill make a diagram that’s more relevant…

coffeekingFree MemberPosted 13 years agoHmm boiler to hot water store, not keen on that idea with modern combis but it would make sense with other methods.

StonerFree MemberPosted 13 years agohere you go. Just knocked this up. Doesnt show all the detail but just how sources and uses of energy are laid out relative to each other.

One of the important bits is the set of opposing pumps between the boiler tank and thermal store which manage energy between the two.

StonerFree MemberPosted 13 years ago

StonerFree MemberPosted 13 years agowun ‘undred…..kWh!

Damn and blast…

Everything was going swimmingly, but it seems the s/h pump from eBay keeps binding. Have had it off and open for a clean, but it’s got bound again. Must be some gunk inside the motor body.Temperature sensors all sited and wired up. Controller mounted to the wall and connected to the pump, sensors and an isolating switch. All working fine except the pump. Will strip one more time and see if I can clean it again. If it binds again I may have to get a new one instead 🙁

Controller in middle, isolator above. Pump bottom right.

Working the day job tomorrow so a bit of a break. Then wednesday I finally install the evacuated tubes and start producing hot water!

piedidiformaggioFree MemberPosted 13 years agoThen wednesday I finally install the evacuated tubes and start producing hot water!

…so that’ll be why the weather is turning into a cloudy rainfest then!

coffeekingFree MemberPosted 13 years agoI have decided house heating is impossible due to my current setup but I might use it as a thermal store for my greenhouse instead, keep it warm in the cold nights.

StonerFree MemberPosted 13 years agoFor a greenhouse set up, you could do a cracking salvage DIY job with some black painted radiators and an old hot water cyclinder.

In theory it ought to thermosyphon during the day one way, then come back again at night time! 😉

Just need one of those indirect coils that fits in the immersiion heater hole.

cheesey – was thinking just the same thing this morning listening to the weather forecast 🙁 at least its sunny and tits-oot-tastic in That London today still!

piedidiformaggioFree MemberPosted 13 years agosunny and tits-oot-tastic in That London

Oh yes, it’s lovely in London today!

Special thanks to the girl on the bike yesterday morning in the almost transparent linen trousers riding towards Holborn Circus. You could even make out the pattern in the lace of her undercrackers! It was a shame I ‘couldn’t’ overtake for a bit 😈

coffeekingFree MemberPosted 13 years agoI’ve managed to rescue a pair of full height freezer condensers and a pair of double glazed window panes to match 🙂 Just need the tank.

coffeekingFree MemberPosted 13 years agoGot loads of 10mm microbore spare just waiting for the job 🙂

StonerFree MemberPosted 13 years agoI was wondering, wouldnt you need one at the top for night time and one at the bottom for daytime?

coffeekingFree MemberPosted 13 years agoOriginal plan was to simply circulate the hot air down to a stone heat absorption tank buried under the floor (insulated box with stones in it, I’ve about 1m^3 of river pebbles going spare!) with a small 2W fan and leave the fan running day and night to keep pushing warm air out the bottom overnight, but I’m starting to consider a separate water (better) system that simply heats a tank and a tiny pumped water system that pumps the same heated water overnight around under-floor pipework, but I think the majority of that would get conducted away without expensive insulated flooring etc.

The first has the benefit of cooling the greenhouse during the day too

StonerFree MemberPosted 13 years agofor cheap pumps I

recommendsuggest trying* the 12v ones that are sold at solar project that I linked to earlier.They’re good VFM, reliable and you can run them off an old car battery and solar panel…

he also does fairly cheap hose for them too.

Apprently he sells 1500 of those pumps a year – not just to solar projects but things like motor racing mechanics, fish collectors etc.

* I dont have direct experience but handled one in the shop. Reassuringly heavy and nicely put together. Simple, but compact.

EDIT: CK I may have some spare UFH tubing lying around in the garage if you’re interested.

StonerFree MemberPosted 13 years agoYou thought you could hide….

His dullness returns.

Reflectors fitted to the frames. These just catch that little bit extra insolation that goes past the sides of the tubes and bounces it back at them.

60 tubes ready to be installed. Apparently best not to leave them open to the sun as you fit them as they can get very hot at the copper end after about 5 minutes.

Pump taken off again, opened up and flushed. Hopefully will run OK. Controller on and programmed to work at dT+6degrees and off at dT+3degs.Probably start raining again when it’s all done….

TandemJeremyFree MemberPosted 13 years agostoner – IIRC I have a central heating pump you could have for postage.

StonerFree MemberPosted 13 years agoThanks TJ. will bear in mind If this one starts giving anymore gyp.

first 20 tubes in. Manifold temp started at 16deg this morning. Now at 33deg and climbing by 0.1deg every 4 seconds under intermittent sunshine and cloudy skies.

time for breakfast.

StonerFree MemberPosted 13 years agoUnfortunately for a PV array to power a 40W ish 240v pump for 10 hrs a day, Id need something like a 200W array which would be about £600 plus £100 for a 100AH battery and £50 for an inverter….

And that probably would still suffer in winter.

But your thinking’s nearly sound cheesey! 😉

StonerFree MemberPosted 13 years agosorry for the delay there sunshine fans….

Events. Events.

Anyway…thermal paste on the business end:

20 in.

60 in

Finished installing the tubes by 13:30 this lunchtime, and I think promptly boiled the water, but had to rush out so set the fan speed to pos 3 (fast) to make sure it didnt do anything silly. Just got back and everything seems OK.

Have adjusted the call for heat trigger temp for the boiler so that it fires at 55deg, not 65deg and shuts off at 75deg not 85deg. I want to keep a decent wodge of cooler water at the bottom of the thermal store to make the most of the array energy.

Its going to take a bit of time to get the temp settings bang on, as well as the pump speed setting, Im not sure that pos 1 isnt too slow in mid summer…we’ll see.

I think I will replace one of the manual bleed vents with an auto one OR re-route the expansion overflow so that it comes from the return bleed vent tail because when it was stagnating there was quite a bit of knocking and I think it’s because of the route the pipes take when they come into the building. Not a trained plumber so some trail and error to expected…

piedidiformaggioFree MemberPosted 13 years agoTop work!

No, those lines in your grass need investigating. I suggest that we all come round and do a STW syle ‘Time Team’ investigation.

woody2000Full MemberPosted 13 years agoGood work Sir 🙂

I thought I had a decent size garden, but yours takes the biscuit 🙂

The topic ‘Solar water thermal panels: The installation… (w pics)’ is closed to new replies.