- This topic has 748 replies, 176 voices, and was last updated 11 years ago by turin.

-

Rate my Brickie….

-

wwaswasFull MemberPosted 11 years ago

and again

[edit] we end up with more glitch bumps than posts after the first 10 pages.

weeksyFull MemberPosted 11 years agoThis is all insanity taken to the next level…. i’m truely truely bemused by it all.

footflapsFull MemberPosted 11 years agoThis is all insanity taken to the next level…. i’m truely truely bemused by it all.

Just wait till I add the swimming pool for the sharks with lazer beams on their heads…

footflapsFull MemberPosted 11 years agoIsn’t that beam going to be a massive cold bridge?

Probably – will get boxed in at some point.

EDIT: Won’t be that massive as the edge surface area is tiny.

MurrayFull MemberPosted 11 years ago<slight highjack>What do you do about cables/sockets if you use Celotex boards? Presumably they’re a potential air leak and heat bridge. I know there must be a good answer but at 04:00 in bed this morning I couldn’t think of it.</slight highjack>

footflapsFull MemberPosted 11 years agoAs it’s a workshop, I’m going to surface mount all the electrics as I don’t care if it’s not flush. You can get recessed sockets etc for insulation and it wouldn’t make a significant difference in the overall U value for the whole building, but that would involve knowing where I want all the lights etc before I insulated, and I haven’t thought about that yet….

I know there must be a good answer but at 04:00 in bed this morning I couldn’t think of it.

Hmm you too? I thought I was the only one lying awake at night thinking about what to do next / how to do it…..

footflapsFull MemberPosted 11 years agoGeeky info on the insulation fixings – found the data sheet:

Spit ISO Insulation Anchor by brf, on FlickrfootflapsFull MemberPosted 11 years agoTonight’s activity was fitting the RSD. Total PITA as the instructions were next to useless and the motor roller is too wide for the opening, so either one of the guides is bent, or the shutter can pop out.

’Auto-Roll’ Roller Shutter Door Installed by brf, on FlickrweeksyFull MemberPosted 11 years agoAre you running a business out of the workshop or just for day to day stuff ?

wwaswasFull MemberPosted 11 years agoAre you running a business out of the workshop or just for day to day stuff ?

It’s literally a bike shed.

davidjones15Free MemberPosted 11 years agoTotal PITA as the instructions were next to useless and the motor roller is too wide for the opening, so either one of the guides is bent, or the shutter can pop out.

Didn’t it arrive as a plug and play, pre assembled unit?

Who did the measuring? I’m not sure what the problem with the guides is either.footflapsFull MemberPosted 11 years agoWho did the measuring? I’m not sure what the problem with the guides is either.

I measured the opening and they cut the thing to size and deliver it in parts:

Roller Shutter Door by brf, on FlickrThe problem is, they don’t cut the motor to size, but (I guess) have a range of set length and each motor roller has a bar on one side which slides in and out to allow flexibility for a range of openings.

However this one is too wide for the opening (ie the adjuster bar doesn’t retract enough) so the right hand flag pole bracket is pushed right out at the top, twisting the frame. The spacing of the vertical tracks is specified at shutter width + 40mm, which is what I’ve installed it at. To fit the motor, it needs to be +60mm, which will reduce the shutter overlap in the guide rails from 20mm to 10mm, which would be quite easy to pry out. I may dismantle the whole thing and cut the expansion bar in the roller.

As for the electrics – no instructions, 4 wires (coloured) and a PCB with non-colour, non-industry standard labels (NB I am a Chartered Electronic Design Engineer, so do know about these things). I just applied pot luck and guessed ok first time – but pretty shoddy as all they needed was a piece of paper with 4 lines on it…

I wouldn’t recommend Auto-roll to anyone.

footflapsFull MemberPosted 11 years agoAre you running a business out of the workshop or just for day to day stuff ?

I went for the RSD for security and also, ‘out of sight, out of mind’. The main door is a glass patio door for light and convenience. The RSD is just to close at night for security.

These get fitted at the WE:

marcus7Free MemberPosted 11 years agoGood God, that is by far BY FAR the most “over the top” bike shed i have ever seen EVER, it must be costing a fortune! well done, I am very impressed!

davidjones15Free MemberPosted 11 years agoI’m not too clear on the problem, but it sounds like the laths are too short, no?

That is to say that the minimum width is determined by the motor (and weight of shutter) and not the opening. The guides and laths should fit this and would be oversize for the specified opening.Get back on to the supplier with this and tell them that as they are the experts they should have pointed this out. You relied on their expert opinion and they gave bad advice. It shouldn’t require any more than a new set of laths.

That depends on whether I have understood correctly or not. Photos of the problem would be good.

It is a bit of a nightmare doing these things on line though.footflapsFull MemberPosted 11 years agoEither way I have to take it all down, it which case I may as well cut 20mm off the motor axle expansion bar thing and re-fit it. Quicker and less hassle than them sending me a new motor roller….

As for taking it all down, putting it all up – the shutter door is a two man lift and has to be held up vertically to be bolted to the motor roller, requiring a third set of hands. Mrs FF and I managed it with a make shift hoist, some blood loss, a lot of swearing and then a lot of chastising over my swearing. Not something I’m looking forward to again….

bruneepFull MemberPosted 11 years agoAre you accessing the cave via an underground tunnel, or are the doors just laid on the grass?

davidjones15Free MemberPosted 11 years agoEither way I have to take it all down, it which case I may as well cut 20mm off the motor axle expansion bar thing and re-fit it. Quicker and less hassle than them sending me a new motor roller….

Not good however you look at it.

footflapsFull MemberPosted 11 years agoAre you accessing the cave via an underground tunnel, or are the doors just laid on the grass?

I’ve installed ICBMs in the lawn as a deterrent, the doors are just until the proper steel launch doors arrive for the ICBM chambers…

As for the workshop, this is how it should look after the first fit:

kingkongsfingerFree MemberPosted 11 years agoFootflaps, pm me if you need help with the RSD, I have been fitting and selling industrial doors inc. the RSD type you have for over 20 years, I will help you if needed.

For the record, thats how a RSD is delivered, bundles of 6-8 lath and you put the sections on one by one by bending one of teh nylon endlocks to the side and then slide the other section in.

The lath is a standard 75mm 22 swg scrolled type, side guides look a bit cheap and flimsey. i cant see the motor to comment on it.

easy way to install the RSD with no instructions is measure overall the nylon endlocks on the lath and they fix the sideguide angles about 30 mm wider than this measurement. Make sure they are plumb and sqaure. Drop the barrell in the cups on the endplates and then fix that lath in sections as I mentioned starting from the top. Its V important that the first section of lath is fitted square and level on the barrell as the rest of the door curtain with roll up on the p155 and “bag up” and jam. Last thing is to fit the guides to the guide angles and set the motor limits. That size door is 1.5 hr job max.

kingkongsfingerFree MemberPosted 11 years agoAgreeded about Autoroll in the NE, they “used” to be one of my customers, as i used to supply them parts to manufature and repair doors. No further comments needed.

footflapsFull MemberPosted 11 years agoeasy way to install the RSD …….

Thanks! I have no sussed it all out, just it would have been nice to have had decent instructions with it….

The hardest bit was lifting the whole thing up to bolt to the motor, using just the edges of the shutter. How do you do it?

Tonight I’ll fit an eye bolt into the blocks above it, so I can just take the weight on a rope and haul it up and down rather than trying to hold it in place and bolt it all whilst two people are standing on a step ladder.

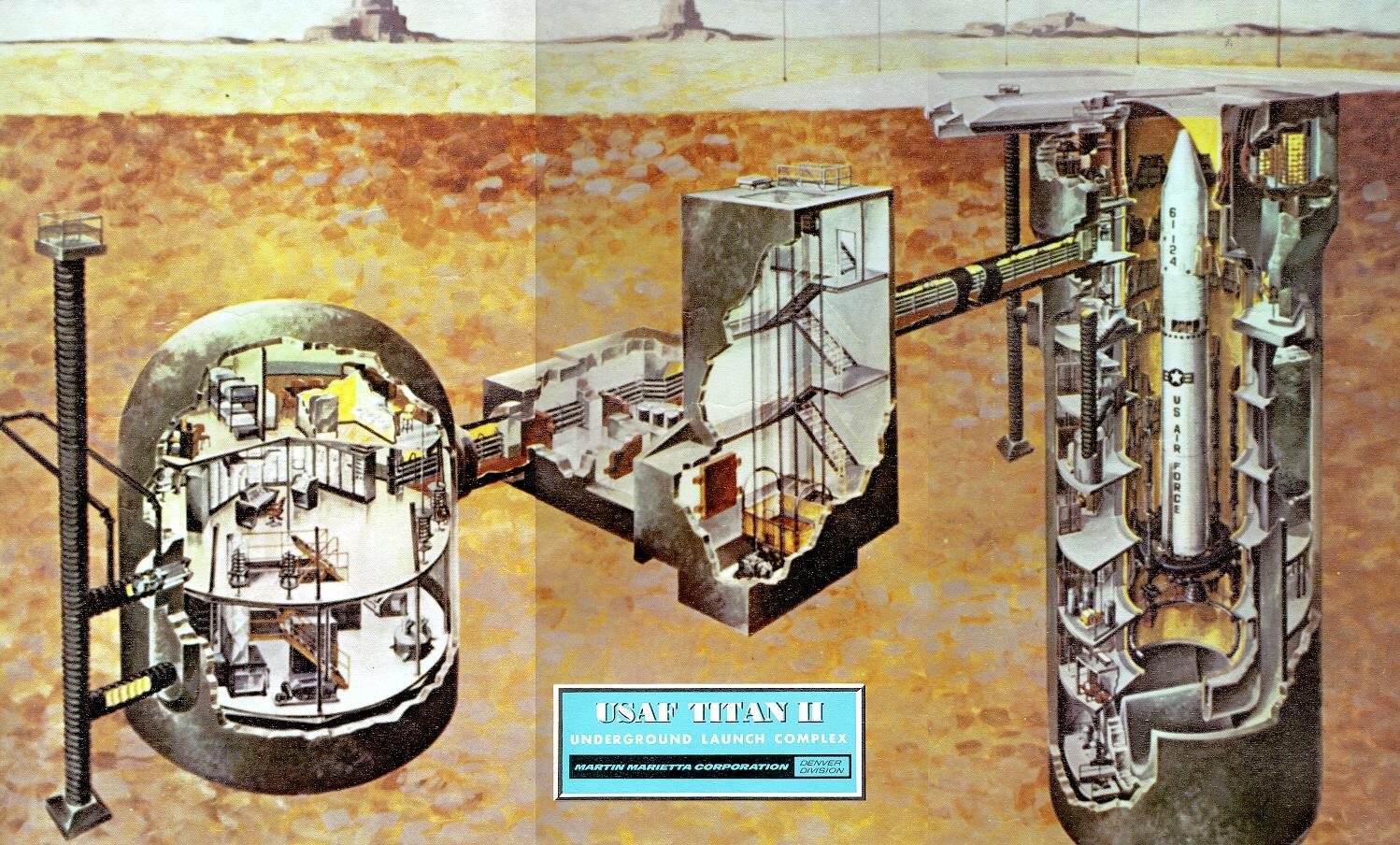

footflapsFull MemberPosted 11 years agoShould’ve went for the Titan 3

I found a second hand Titan 2 kit on Ebay going cheap. Only fired once – seemed like a bargain to me…..

davidjones15Free MemberPosted 11 years agoHow do you do it?

You could mount the guides to the end plates to form a big U.

With two people simply lift into place and screw down.kingkongsfingerFree MemberPosted 11 years agofootflaps – Member

easy way to install the RSD …….

Thanks! I have no sussed it all out, just it would have been nice to have had decent instructions with it….

The hardest bit was lifting the whole thing up to bolt to the motor, using just the edges of the shutter. How do you do it?

Tonight I’ll fit an eye bolt into the blocks above it, so I can just take the weight on a rope and haul it up and down rather than trying to hold it in place and bolt it all whilst two people are standing on a step ladder.

Not 100% sure what you mean. If you have already installed the two side guides, you then need to fit the barrell next. You do this (with a small door like yours)by putting two ladders between the guides resting on the lintol and two people put the barrell in there arms like a baby, walk up the ladders together and then drop the barrell shaft into the cups on the endplates. Make sure their is some type of fixing that stops the barrell shaft coming out of the shaft when operating, this would be a disaster if it came out. We used to sell this type of door upto 7 m square!!! Imagine the size and weight of the barrell 7 metres long to stop the deflection, it was a hard days graft fitting them!!

kingkongsfingerFree MemberPosted 11 years agoRe. the above fixing info, I am assuming than the endplates are already bolted, welded to the side guide angles (they should be) These are known as flag guides, as they look like falgs when you stand them up to fix them to the structure.

footflapsFull MemberPosted 11 years agoNot 100% sure what you mean.

Installation order was:

1) Flag poles into wall

2) Roller motor into flag polesThat was all quite straightforward. Hard bit was lifting the whole 2.5m roller shutter up to the barrel to bolt in place. Heavy and hard to grip as you need one person each side, on step ladders (we only had one).

footflapsFull MemberPosted 11 years agobump x3

What’s with the whole ‘Slow down you move to fast’ nonsense – you need 3-4 extra posts just to get the next page to work properly……

flatfishFree MemberPosted 11 years agoConcur with Kingkong.

I’ve been fitting RSD’s for about 15 years too.

davidjones15Free MemberPosted 11 years agoQuick vid on mounting guides and box.

[video]http://www.youtube.com/watch?v=GF562LADELM[/video]franksinatraFull MemberPosted 11 years agoGood God, this things is a fortress. Do you have even a tiny bit of doubt in your mind that it might be slightly overkill?

Is there not a risk that a master burglar will try to rob you just for the challenge, bit like in Oceans 11?

Edit (still love it though, well done!)

kingkongsfingerFree MemberPosted 11 years agodavidjones15 – Member

Good video and try. But wrong type of RSD, wrong application for an industrial type roller shutter for the “mega structure!”

footflapsFull MemberPosted 11 years agoDo you have even a tiny bit of doubt in your mind that it might be slightly overkill?

It is a project, rather than a means to an end, plus I already have a wooden shed, so thought I’d try something a bit different….

The topic ‘Rate my Brickie….’ is closed to new replies.