Home › Forums › Bike Forum › Chain length on 1x setup, clearly wrong

- This topic has 26 replies, 13 voices, and was last updated 1 year ago by thols2.

-

Chain length on 1x setup, clearly wrong

-

bcfse1Full MemberPosted 1 year ago

Hello all

I spent the weekend building up my old 26″ hard-tail (On-One Inbred geared) which has sat abandoned in the loft since wheels, saddle etc were “quick-released” from the secure bike locker in the flats I was living in 10+ years ago.

A few months back I picked up some Mavic+XTR 26″ wheels (centre-lock) and used XT M8100 brakes for decent prices on ebay. New brakes because my old original Hope Minis from ~2002 needed some work and new rotors (since the originals were nicked with the wheels) so it was cheaper to buy new. Then discovered that my original XT 9-speed shifter wouldn’t fit under the fluid reservoir of the new brakes. Since I had been bike-less for 10 years and not contributed to the bike economy for 15+ years I decided to buy some new groupset… Deore M5100 rear mech, shifter and crankset to make a 1×11 setup (11-42t casette and single 32t ring).

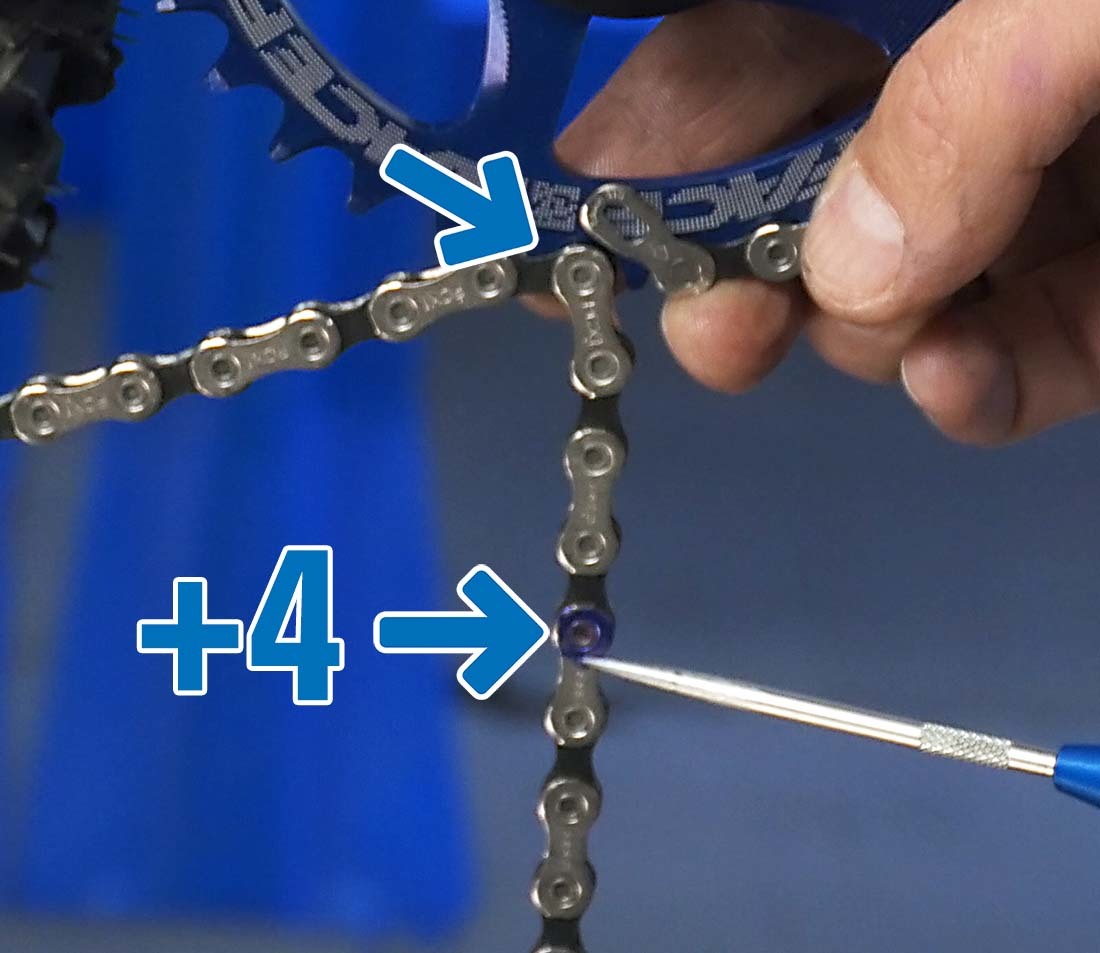

So this weekend I started building. I was installing a SRAM PC X1 chain (I have always run SRAM chains on Shimano groupsets and had great results) and did the usual thing when sizing: largest ring (it’s a 1x setup anyway) and largest sprocket then add 4-5 rivets to match. This is even how the Shimano dealer manual (DM-MARD001-05-ENG.pdf) says to do it on page 12.

However with the chain connected and under tension I can only just shift up into the largest sprocket and the chain bypasses the top jockey wheel and rides the “Chain derailment prevention plate” that sits in the cage between the jockey wheels.

Picture link because attachment didn’t show: https://drive.google.com/file/d/19meGwo0UjjS864y8Md49NI5NGD3WT0XF/view

A pretty grim sight I’m sure you’ll agree. I haven’t even got around to adjusting B-tension or anything yet. Clearly I should have checked this before getting excited and joining up the chain. Everything else I double-checked as I went along, since it’s new tech/standards to me (centre-lock rotors, post-mount calipers, hollowtech BB/cranks) but chain length was just using the formula I was always accustomed to.

So obviously I need to break the chain and add a couple of links in there. But my main question/point is… clearly there is something wrong with the established chain length methodology that fails to take into account larger jockey wheels and a long derailleur cage.

Has anyone else discovered a need to add a couple of extra links with oversized jockey wheels, long-cage derailleurs and shorter chainstays on 26″ frames? It’s also likely that I was just mildly hungover and distracted by le tour.

Cheers, B

matt_outandaboutFree MemberPosted 1 year agoand did the usual thing when sizing: largest ring (it’s a 1x setup anyway) and largest sprocket then add 4-5 rivets to match.

That is an odd way of doing thing! Every chainstay is different length…

I put the chain on full length on largest cog and largest chainring – then eyeball where to reduce the chain down to.

1KramerFree MemberPosted 1 year agoIt’s also likely that I was just mildly hungover and distracted by le tour.

I think this is the likely root cause analysis.

bcfse1Full MemberPosted 1 year agoAbsolutely – you’re right. Clearly I should have just routed the new chain through the derailleur and worked from there visually.

Even the well-known Park Tool guide (https://www.parktool.com/en-int/blog/repair-help/chain-length-sizing) says that for dedicated 1x systems…

Without passing through the rear derailleur, route the chain over the front ring and the largest rear spocket. Determine the shortest length where a chain would connect inner and outer plates. From this point, count 4 rivets as the point to shorten the chain. This is an addition is 2 rivets (1-inch) more than non-dedicated 1X system.

I added an extra ~2 inches and still came up short.

2theotherjonvFree MemberPosted 1 year agodo you mean you counted the front and rear rings and then added 4-5 links, or to me the established way is put it in big-big (OK, you’ve only got one front) bypassing the derailleur and add a couple to that?

I can’t see that if you’ve done the latter that has 4-5 more added, I’d expect chain to be a lot looser?

bcfse1Full MemberPosted 1 year agobig-big (OK, you’ve only got one front) bypassing the derailleur and add a couple to that?

Exactly that. Basically looked like this from the Park Tool guide…

Once some pliers arrive that will let me open the SRAM PowerLock I’ll re-size the chain and I’ll discover whether this was in fact a “me” problem 😐 The more I think about it, the more likely it could have been that I just messed up.

theotherjonvFree MemberPosted 1 year agoOnce some pliers arrive that will let me open the SRAM PowerLock

Use a bit of string.

5labFree MemberPosted 1 year agothat image doesn’t look like you’ve added 4-5 rivets – it looks almost taught. I suspect you may have mis-measured

there’s a bunch of ways to open a powerlink without pliars, eg https://www.youtube.com/watch?v=e5N2wcsNFJc

montgomeryFree MemberPosted 1 year agoYour method sounds fair enough to me. It’s how I do it (on a hardtail). I have on occasion thought ‘oh, might be better if I squeeze in two more links’ but invariably found that when I tried the mech couldn’t cope in the 11 tooth cog.

1bcfse1Full MemberPosted 1 year agoI did try looping some string around the PowerLock and applying opposite force like that but my hands started hurting. Tried again with gloves and worked like a charm!

Anyway… funny story!

that image doesn’t look like you’ve added 4-5 rivets – it looks almost taught. I suspect you may have mis-measured

^ was correct!

It’s also likely that I was just mildly hungover and distracted by le tour.

…

I think this is the likely root cause analysis.

^ was also correct!

I completely mis-measured. Added the correct number of links and now it looks and runs nice and smooth. Apologies for the unnecessary forum pollution!

However I now have a chain with a re-used PowerLock and some links added by breaking the spare run of chain and riveting into the active chain. Would it be advisable to switch to a fully new chain? I’ll grab some extra PowerLocks anyway just to have some spare and might replace the one I just re-connected. I used to undo and re-do the old PowerLinks on 9-speed fairly frequently but the tolerances of 11 speed are much narrower.

Cheers, B

theotherjonvFree MemberPosted 1 year agoA powerlock will be OK to be reused IMHO, certainly one that’s only been opened once.

I wouldn’t bin the chain, get another powerlink and add that in place of the join. Don’t **** up working out where to take the link out from.

mertFree MemberPosted 1 year agoThe only issue you’ve got with the chain is the re-riveted joint. The rivets are peened on modern chains to ensure they don’t pop out, you’ve removed the peening, the chain will most likely snap. (actually, they’ve been peened since 8/9 speed days)

Buy another quick link and replace the rejoined rivet/plates.

Powerlocks can be reused, hell, i’ve watched SRAMs own race techs reuse them.

Once the positive click goes, it’s time to replace.

noeffsgivenFree MemberPosted 1 year agoThat photo made my eyes water, didn’t think they could go that far, it was like watching Ariane lipski’s kneebar submission in the UFC, ouuuuch😬. Never heard the rivet counting method before, I count links, maybe avoid that method from now on.😀

theotherjonvFree MemberPosted 1 year agoit was like watching Ariane lipski’s kneebar submission in the UFC

That’s a phrase I won’t be googling……

bcfse1Full MemberPosted 1 year agoHello all. I’m back… bike build completed at the weekend!

The 2nd-hand XT M8100 brakes I got were cheap because they needed the hoses re-attaching to the levers… all good. Much less of a drama with Shimano brakes than I was expecting to be honest, just had to wait for the connection kit with olives/inserts etc to arrive. Filling with mineral oil/bleeding was also much easier than my old Hope Minis.

Anyway, I celebrated with a few laps around the local roads… first time riding a (non-spinning class) bike in about 10 years! Felt alright, slight bit of adjusting needed etc.

Some observations/questions:

1) Chain length. I haven’t even really seen many 1x setups in real life… does this look messed-up with the chain too tight still, or just about ok?

2) Driveline. This was never a consideration preiously but with 1×11 it makes sense to at least think about it. When looking at the driveline from above it sort of looks like in most sprockets there’s a bit too much crossover of the top of the chain vs the line at the bottom where it enters the derailleur. Is it worth adding 5mm deeper bolts to the chainring to move it more to the middle?

3) B-Tension. The b-tension screw is fully out and the teeth of the top sprocket are about 20mm from the line on the RD-M5100. The manual (https://si.shimano.com/en/pdfs/dm/MARD001/DM-MARD001-05-ENG.pdf) suggests the line should line up with the teeth of a sprocket… no chance! Though perhaps it should be position C I should be adjusting to due to a single chainring…

4) After my celebratory laps of the estate, the rear tyre completely deflated. On inspection a split had developed in the brand new inner tube just behind the valve, and the valve was sort of pointing forward.

My thoughts are: not enough pressure and the tyre drags the inner tube under braking, causing the valve to hyper-extend at the base. Or would that be too much pressure? Or badly-fitting/old tyres (I intend to replace with more gravel/road 26x 1.9s anyway)? Rim tape needs replacing or extra padding around the valve entrance on the inside of the rim? Perhaps these brakes are so powerful and I’m carrying a bit more bark than 15 years ago (not too much mind)!

Wheels are Mavic 317 disc 559×17, Tyres 26×2.1, tube Continental presta 26x 1.75-2-5

I have literally never had this before, though I always avoided presta valves so perhaps I’m just being an idiot.

Any comments/suggestions on this latest set of dramas?

Cheers, B

theotherjonvFree MemberPosted 1 year agoChain looks about right to me.

Chainline – it’ll always be a compromise on a 1x, for me I generally ride most in about 6th or 7th (on a 1×10) so if anything my chainline would be ideal slightly outside of centre. OTOH that means that the low gear are a bit more crossed, and as a result seem to grind a bit more – but also when I’m in lowest gears I’m doing 5mph up a hill so you can hear the drivetrain rather than wind in your ears and the clatter of bike over the trail, so maybe it’s not that different.

B-tension – tbh I’ve never fussed that much over B-tension so can’t give much advice. Does it shift ok?

Inner tube – possibly but tighten the locknut to hold it tighter, and also dust your inner and inside of the tyre with talc. Is that a presta through a schrader hole? Maybe get some inserts if so?

bcfse1Full MemberPosted 1 year agoThanks for the reply.

Chain: yeah it’s alright I think. I’m just not really into the aesthetic of massive dinner-plate cassettes and too-small-looking front rings. Guess it looks even more odd on 26″ wheels. No point even having that largest sprocket anyway to be honest, feels slower than walking pace. Probably will end up switching to a 34t chainring to give a bit more push on the roads, as this bike will probably be mostly road and very hard-pack XC/gravel.

Chainline: doesn’t clank/grind too much when in the largest sprocket. Though the angle that it interfaces the chainring looks a bit disturbing at first glance. Perhaps 3mm of spacers might just even it out.

B-tension: shifts fine actually. Sometimes a bit hesitant on the way down, and when going up into the larger sprockets, but close enough to leave for a few weeks to bed-in under tension then adjust a bit more,

Inner tube: I put some talc around the tube but not the inside of the tyre. However, wouldn’t the talc reduce the friction? Thinking more about it, if anything surely I should make sure that the tyre isn’t slipping on the rim under braking at all to even cause any rotational force on the valve. The rims are drilled for presta valves. I’ll have more of a look tomorrow. Unfortunately I don’t have a tyre pressure gauge for presta valves – might buy a cheap track pump rather than my small trail pump.

Cheers!

2theotherjonvFree MemberPosted 1 year agoBut if the tyre does slip on the rim you don’t want it to drag the tube with it and tear the valve, hence lube them both

SpeederFull MemberPosted 1 year agoWhen I used to use tubes, I’d apply a liberal coating of talc to the inside of the tyre. Only issues are that you smell a bit funny and if you do need to patch the tube, it’s a bit of effort to get the talc off. The talc does mean you’re much less likely to get pinch flats though.

bcfse1Full MemberPosted 1 year agoAs a final update to this after being away, I got a track pump so I could actually check tyre pressure. It turns out it has been so long since I did bikes that my judgement by hand of a decent tyre pressure was way wrong, I was inflating only to about 30 psi rather than the 45-60 psi range that the tyres wanted. No wonder the tube was wandering all over the place within the tyres.

Running at a decent 55 psi now and no problems over the last week. It’s a beautiful feeling when a bike is all clean, tightly-bolted, nicely-fettled and well-lubed. No clunking/clicking, just the sound of tyres rolling. I now have a working bike again for the first time in 15 years – YESSSSS!!

Thanks all!

mashrFull MemberPosted 1 year agoRunning at a decent 55 psi

On this bike???

26″ hard-tail (On-One Inbred geared)

SpeederFull MemberPosted 1 year ago55psi is a bit much for off road, you’ll be pinging off everything. ignore the numbers on the sidewall – especially on Maxxis. Somewhere between 20 & 30 is where it’s at depending on how hard you’re riding and what tyres you’re using.

thols2Full MemberPosted 1 year agoThe original photo shows a 2.1″ tyre. I wouldn’t run that higher than 35 psi, normally 25 to 30 off road.

If you’re running tubes, clean the inside of the rims and the tyre beads with dish detergent to degrease them. Then put plenty of talc inside the tyre. The idea is that you want the tyre to grip the rim, but the tube to slip inside the tyre.

bcfse1Full MemberPosted 1 year agoSo I actually switched to a pair of these https://www.tredz.co.uk/.Continental-Double-Fighter-III-26-inch-MTB-Tyre_80088.htm since this bike will be mostly hacking about on road or gravel/tow-paths

rootes1Free MemberPosted 1 year ago3) B-Tension. The b-tension screw is fully out and the teeth of the top sprocket are about 20mm from the line on the RD-M5100. The manual (https://si.shimano.com/en/pdfs/dm/MARD001/DM-MARD001-05-ENG.pdf) suggests the line should line up with the teeth of a sprocket… no chance! Though perhaps it should be position C I should be adjusting to due to a single chainring…

All that depends on which cassette you are using, but also which version of the 5100 mech you are using. I think from look at your setup it is not one that you can match up to the options in the guide (appears to be RD-M5100-SGS and 11-42 cassette).

closest in the guide would 10sp 11-43t cassette with a RD-M5130-GS mech – see option (B), but GS is a shorter cage and that along with option (C) only applies to shorter cage mech.

RD-M5130-GS might have been a better option for your setup.

But if it works all good!

thols2Full MemberPosted 1 year agoSo I actually switched to a pair of these

That’s a 1.9″ tyre. On road, I wouldn’t run it over 40 psi, off road 30 to 35 on the back, 25 to 30 on the front.

You must be logged in to reply to this topic.