In our final interview from Bespoked, Manchester, I stopped for a chat with Alex from Atherton Bikes to see if I could find out what’s ahead for the Welsh brand.

I think this is the newest model – want to talk us through it?

This is the S170, so it takes a lot of the DNA from our A170, but the primary difference being the S stands for Subtractive rather than Additive – so CNC rather than additive manufacturing as we have for the A series. The rear end is one piece – rather than being DW6 on the A series, this one is DW4, so a slightly less dynamic linkage. In terms of maintenance, you can see that all the cables are really easy to access, less bearings for the rear end, so it’s very much the kind of ‘get out there, don’t worry about it, ride it’ – something I think will really resonate with the UK market. So that’s primary differences between the A and the S series. Both still come with the same lifetime warranty.

Unique content like this takes time to create, and would normally be paywalled. But we’d like to support the independent builders and makers behind these bikes, and Bespoked. So you’re getting to read this for free. If you enjoy it, please consider joining us, and supporting what we do.

Okay, so this is the S170, 170 being rearward travel and then S being subtractive. And what travel will go up front?

So you can go 170, 180, just accounting for a slightly shorter reach if you’re running 180mm. We have had some people do dual crown, but it’s not official yet! (Editor’s note: the S170 has now been approved for dual crown forks)

I can see daylight through there, I sort of wasn’t expecting to see daylight anywhere.

Some of the lugs have got cutouts for weight saving, so it’s fairly industrial to look at, but all of this is based around the idea that this is about performance, it’s not about aesthetics. Obviously we think that we found a nice balance between the two! But this is very much a performance focused bike. A way you could look at the S170 maybe versus the A170, is that this S170 is maybe like more of a park bike if you like, so it can absolutely take big hits like at Dyfi Bike Park and bigger stuff. You could happily race this on maybe our domestic downhill scene and you’d be well catered for, but this is the more all-encompassing 170 bike with that slightly less dynamic rear end.

And is it still being made in the Dyfi Valley?

It’s being assembled in Dyfi. Our A series is all in-house. For this one with CNC we obviously don’t have facilities to CNC in-house at this point, so we work with a few suppliers to do that part.

There’s less stages in production for this one, so once we’ve kind of got the lug kit and the tubes ready to go, it’s bonded in-house and then it’s sent straight to the workshop pretty much, because it’s all done at that point, whereas for the A series after it’s bonded it would need to be cable routed and then it would need to go to paint. So much quicker for us to get through in that sense.

And is it all standard geometry or is there some customisation to be had here?

With the A series – 130, 150, 170 – they have 22 sizes and the A200 has 12 sizes. For the S series we have 12 sizes, so it’s still 10mm increments in reach between those sizes, but it’s 12 rather than 22 as you’d find for the A series.

That’s some incremental differences, it might be quite hard for people to choose. Can you come and test ride them and try them out?

Yeah, definitely, you can come and demo them with us at Dyfi. Equally, we’re doing events this year where we’re trying to get demo bikes out to people, so we did one recently at Windhill which was really cool and there’s going to be a few more in the works. On the website, if you go on the events page you can keep an eye on demos that way. Equally, you can go on the website and fill out our fit calculator – you just need to go on the model that you’re interested in and then you’ll find the fit calculator on those pages.

Just give us a call if you’re struggling to find it. You need to provide your height, your arm span and your inseam and then we take those together and then we can recommend you one of those 12 sizes. Equally, you’re very much welcome to give us a call and talk through things, because the fit calculator is a great starting point, but maybe people have some preference already. I think getting a leg over at Dyfi would be the best way, because it doesn’t matter what we say – at the end of the day you just need to ride it and see what you think!

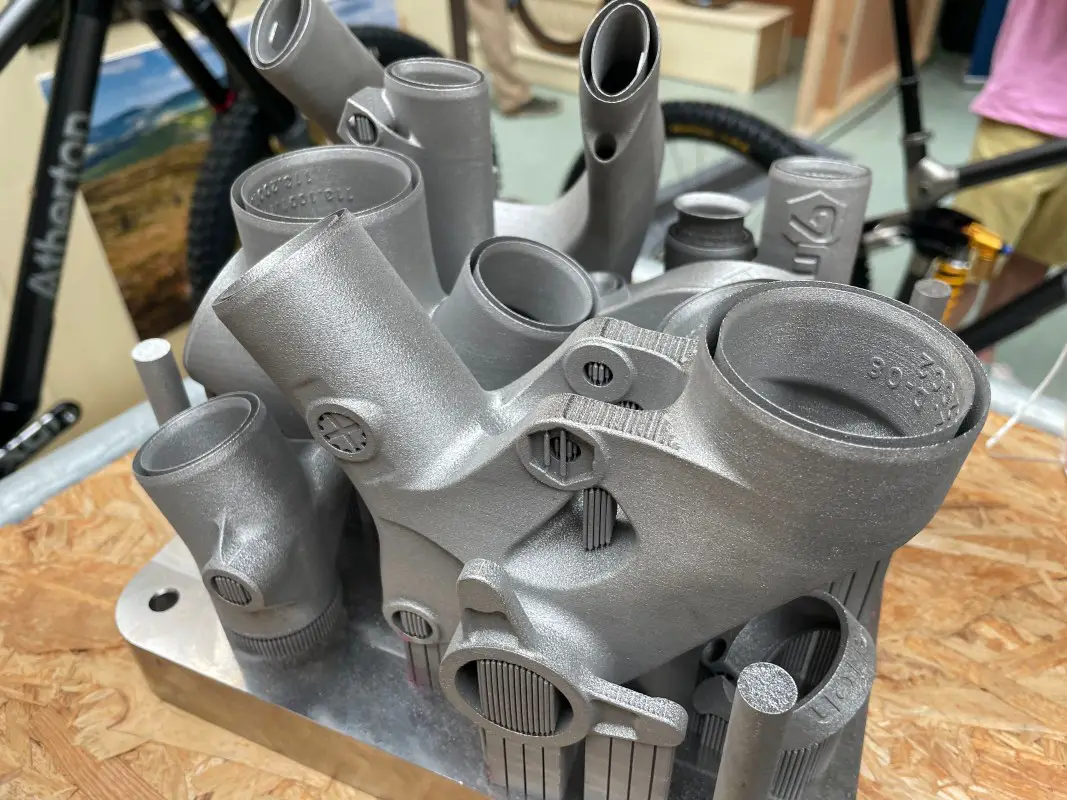

What’s going on here?

That’s part of the machining process for CNC lugs, so it’s referred to as a tool path – so to remove the material from the inside during CNC there needs to be a path for the tool and so that’s why you have that kind of open section. It’s required for the CNC process. You can use it as a stash box but we haven’t put it in like that for it to serve that purpose specifically, it’s just part of the CNC process.

So there’s nothing to stop you losing everything inside there at the moment?

No, you’d need to put it in a bag.

So this is the S170, and on display here there’s also the A170, and the A150. Is the S150 on the way?

We’re working on it. The S170 was the natural choice with the A170 being so popular. I think it just is that real sweet spot. It covers a lot of bases. It’s super at home at the bike park, but anything kind of big and technical, you know, both in the UK and abroad, you’ll be well catered to with the A170 and the S170.

The A150 is a little bit more kind of in between. If you like a little bit of pedalling, it’s definitely my preference. I think the 150 is great if you like your ups and your downs. The one that we’ve got on display here is Luca’s own bike (Luca is Atherton Bikes’ workshop manager). He rides a lot in Aosta Valley and Finale, and 150 is super capable for that. And also, obviously, a lot of stuff in Dyfi Forest that we’ve got on our doorstep. He’s spent a great deal of time polishing and customising his own lugs, so this finish is his own work – not available to buy.

Are you able to tell us what else is in the works? What’s next for Atherton Bikes?

So… the S-Series will be developed further. There’s not much more that we can say to confirm on that at this point. But obviously the range that we’ve got at the moment for A-Series, we’re very happy with and we feel that everyone’s catered to. So it’s not a crazy idea to consider that there might be some additions moving from the A-Series into the S-Series.

OK… we’ve seen Rachel riding around on e-bikes quite a lot. Is there an e-bike in the works at all?

Yeah, again, we’re working on it is all I can say! Obviously it’s quite a small team and these things take time and we want to make sure that we’ve got it right. The e-bike market is moving really fast all the time as well. So we want to make sure that we’re kind of jumping in at the right moment. But we absolutely recognise the value of e-bikes and we want to be in there with our own offering. So never say never. We’re working on it.

What about a kid’s bike? Because Arna is probably in need of a kid’s bike!

I don’t know! I haven’t got anything on that one, but I’m maybe not going to be the person in the know. So again, never say never. If anyone’s going to be on one first, it’ll be Arna. So maybe keep an eye on Rachel’s Instagram for any hints!

Thank you very much and enjoy the show.

Unique content like this takes time to create, and would normally be paywalled. But we’d like to support the independent builders and makers behind these bikes, and Bespoked. So you’re getting to read this for free. If you enjoy it, please consider joining us, and supporting what we do.