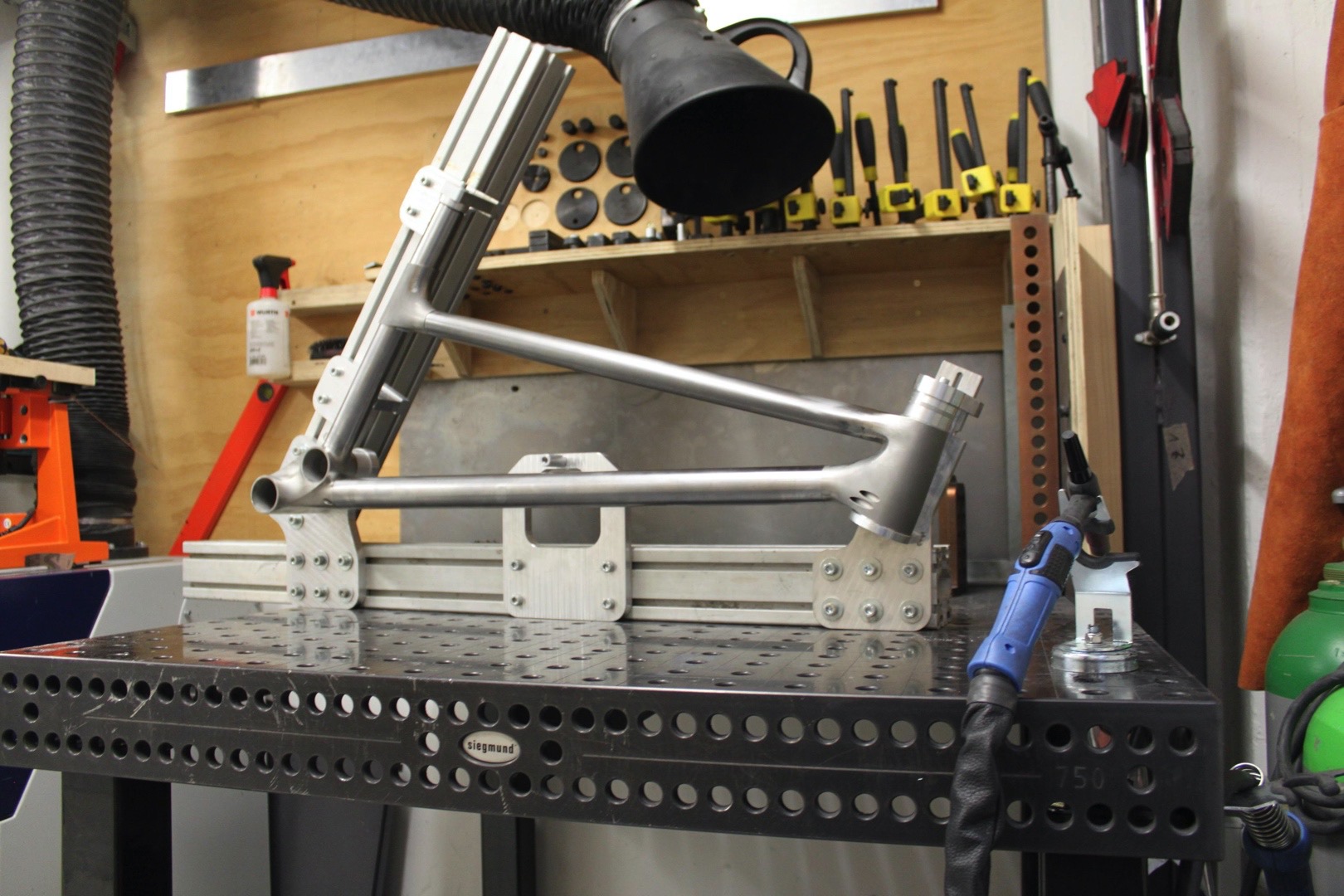

It doesn’t matter what you’re doing, I want you to stop it and soak in the majesty of this stainless steel full-sus Moorhuhn!

Keywords are important when it comes to writing a story. We need to use the sort of words that will not only grab the readers attention but also words that rank well on search engines. It can sometimes be tricky, but not this time.

The Huhncycles Moorhuhn has it all! 3D printed, steel, stainless steel, full-suspension, handmade! Chicken!

Ralf Holleis is the frame maker, engineer and artist behind Huhn Cycles, a part-time frame making business where he uses cutting edge technologies to make ‘sexy’ (his words) frames. Ralf uses his skills to build bikes and frames unlike anything we would normally see, and is a dab hand at building titanium and steel bikes, and will even use carbon fibre on some projects too.

3D Printed

This latest project, the Moorhuhn, takes Ralf’s passion for technology to the next step using 3D printed steel lugs welded into Reynolds 953 steel tubing to create this absolutely stunning full-suspension frame.

Lugs for the seat tube / top tube junction, bottom bracket / main pivot and head tube are all manufactured using a 3D printed process, though others might argue that this is actually an additive manufacturing process close to what Atherton Bikes does.

Internally the lugs feature a honeycomb structure which supports hose and cable routing to keep this stainless steel stunner uncluttered once built.

Stainless Steel

Reynolds 953 is a stainless steel tubing and is an extremely hard metal that is resistant to fatigue. It’s not a material that is commonly used, and we imagine it costs a pretty penny, but what price can you put on a raw stainless steel frame? If only we had a Delorean for shuttle duty!

The front triangle is made completely from 953 which is welded or silver brazed to the lugs. The rear is manufactured from Columbus Zona steel, another high-end steel which is often compared to 853.

Full-suspension

Once all those tubes and lugs are fastened together the result is the Moorhuhn, a full-suspension bike aimed at trail riding with 129mm of rear-wheel travel.

Designed around a 140mm travel fork, the Moorhuhn has a 67-degree head angle, 76-degree seat tube angle and a reach for 469.6mm which results in a 621.6mm top tube length.

Chicken

Huhn is Chicken in German. Why chicken you might ask;

“Getting dirty is fun, chickens live in the dirt, jet they look very elegant!

Chickens walk forward with their heads up high, while doing so they never loose focus.FORWARD EVER BACKWARD NEVER!

Last but not least chickens have the skill to fly for short distances, mountain bikes do the same !”

Ralf Holleis

I’m sure you’re going to want to see more of the Moorhuhn so we recommend that you follow Huhn on Instagram and visit the Huhncycles.com website where there are more images of this stainless steel beauty, as well as details of this!

That’s lovely. Really really lovely. The whole aesthetic of that is incredible from the lugs to the cable routing and the way the top tube flows into the seat stays. Want!

Are we absolutely sure that track bike is “gorgeous”? I mean, I can appreciate that a lot of work and engineering went into it, but….

the shape of all the parts of that full bus are just lovely. Would be interested to know what happens to the cables when they come out of those printed sections – how do they run inside the tubes?

A thing of beauty.

I’d be interested in the strength of the additive technology versus CNC from billet, or forging.

953 is meant to be a pig to work with and very hard on tooling, so can see why they’ve got this route.

@Andi what about this beauty also https://huhncycles.com/BERGHUHN-147

And it’s a single pivot too. Lovely.

That is stunning! Levels of want through the roof right now!

“business where be uses cutting”

Come on Andi.

Interesting frames. How does the weight compare? Have they done comparable fatigue tests?

On a slightly pedantic note – I use Columbus Zona – it is OK but not particularly “high end” and people don’t compare it to 853 (UTS 800MPa vs 1200-1400 and doesn’t air harden etc).

WANT ONE (do they do hardtails too?)

Very very nice.

Glad to see the no brakes hipster **** market is also catered for. Although obviously it will only be ridden on the track. That saddle gives that away.

That goes on my ‘Euro Millions’ list.

Along with an Irish passport.

“Lugs for the seat tube / top tube junction, bottom bracket / main pivot and head tube are all manufactured using a 3D printed process, though others might argue that this is actually an additive manufacturing process”

Two names for the exact same thing

@Northwind you obviously have never spoken to the Athertons then

I have, but it was Gee, so he mostly just said the word gnarly over and over.

I should’ve been a wee bit clearer mind, 3d printing is additive manufacturing but not all additive manufacturing is 3d printing

The Athertons are giving you marketing BS then. It’s the same thing. Just trying to use the term AM to make it sound more serious and therefore justify more expense.

Hmmm, where’s that lottery ticket?…..

There’s this little whining noise trying to escape from my throat having seen this! It’s a thing of beauty to be sure!