Rather than just waiting for her Stanton Switch9er FS test bike to turn up by courier, she went off for a day in the Peak District to see the bike being made, and even ‘helped’ with a couple of bits. While she was there she took the chance to sit down with owner, Dan Stanton, to find out a bit more about his vision for the company. It’s bigger than you might expect…

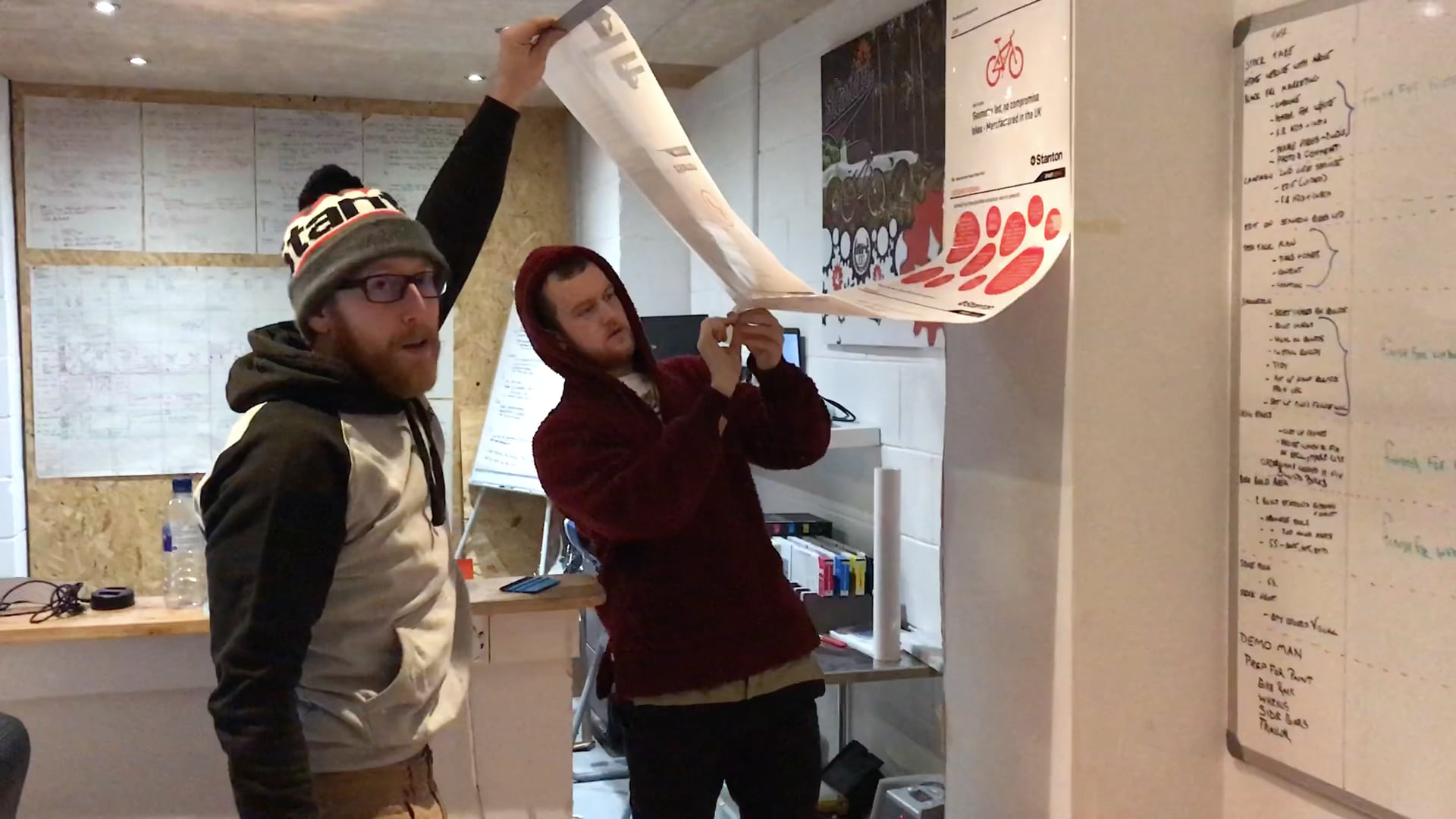

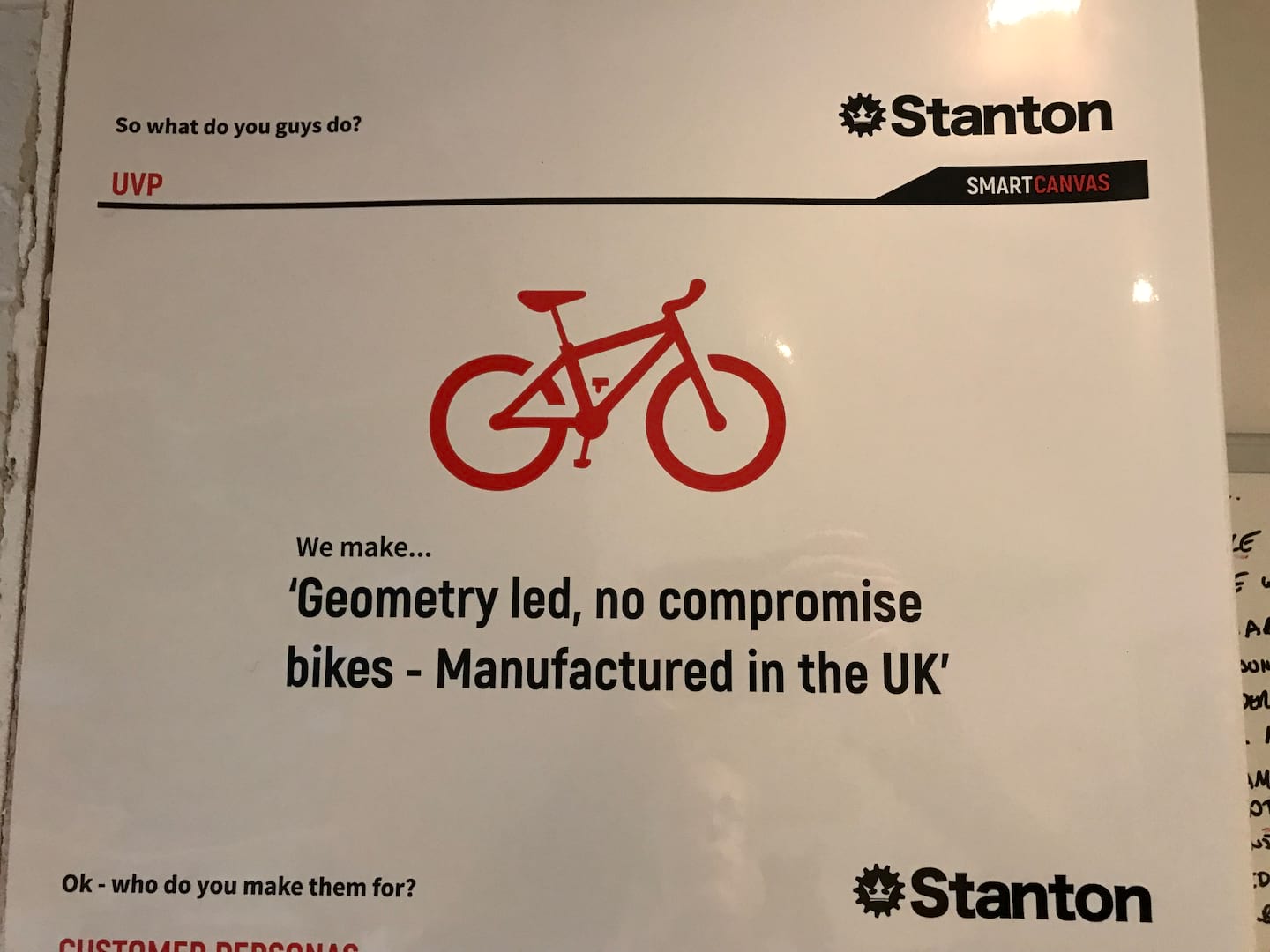

I arrive at Stanton Bikes to find them busy attaching their business plan to the wall. It’s a slick series of infographics, bullet pointed targets, and mission statement. Sadly, perhaps, this is the kind of thing that gets me excited. Business analysis and project planning – my life before Singletrack dealt with this kind of thing, and it’s a level of professionalism not always associated with the bike industry.

In fact, this level of ‘business’ feels a little bit frowned upon. It’s the kind of thing that distinguishes the big corporate bike brands from the boutique ones: sorts the money from soul. But at Stanton there are no qualms about being businesslike – and owner Dan talks enthusiastically about the consultant he’s worked with to get these plans together. He thinks they’re an important part of focusing energy and resources in the right places, and has some clear ideas about how to be a big business without selling your soul.

The Times They Are A-Changin’

Dan started Stanton bikes as an alternative to studying for a PhD in social and political theory. He reels off a series of references to things which I’ve heard of but can’t really claim to understand. It’s a bit like trying to read the blurb next to a piece of modern art that explains what it’s all about. ‘Yeah, Ok, um…the bikes look nice, aren’t they pretty colours?’.

I might not be able to debate the finer points of Marxist theory, or apply a feminist analysis to industrial methods of production, or provide a gender based critique on postmodern consumerist society (yeah, I’m making these up), but I can appreciate passion. I understand enough of what Dan is saying to realise that what he’s talking about is deeply, deeply interesting, and Dan has a fair go at explaining it to me.

He explains the traditional model of mass production of bikes: you estimate how many bikes you’re going to sell, and you order your bikes from the Far East. You pay for them in US Dollars, and the exchange rate means you get a decent profit margin. You wait for your bikes to arrive, and you sell as many of them as you can at full price. Meanwhile, you’re already ordering next year’s bikes, which you’re going to need to pay for, so you start selling last year’s model a bit cheaper, which nibbles your profit margin a bit, but you’re buying in US Dollars and the workforce is cheap, so you can afford to.

Well, that’s how it used to be. But the world economy is shifting.

US Dollars aren’t worth what they once were, and neither are the pounds we use to buy them, so your profit margins are a lot slimmer. You’d better get really good at predicting how many bikes you’re going to sell this year, because selling them off cheap could start to hurt. That colour wasn’t so popular as you thought it would be? Oops. Ouch.

Bringing It All Back Home

What Dan is doing to overcome this, is bringing the manufacturing back to the UK. By taking the uncertainty and waste out of the process and having greater control over manufacturing, he says he will be able to sell a UK made bike for the same price as if it had been made in Taiwan. Instead of ordering bikes by the hundred many months in advance, he’ll be able to make bikes to order, or in small runs, right there in Stanton HQ.

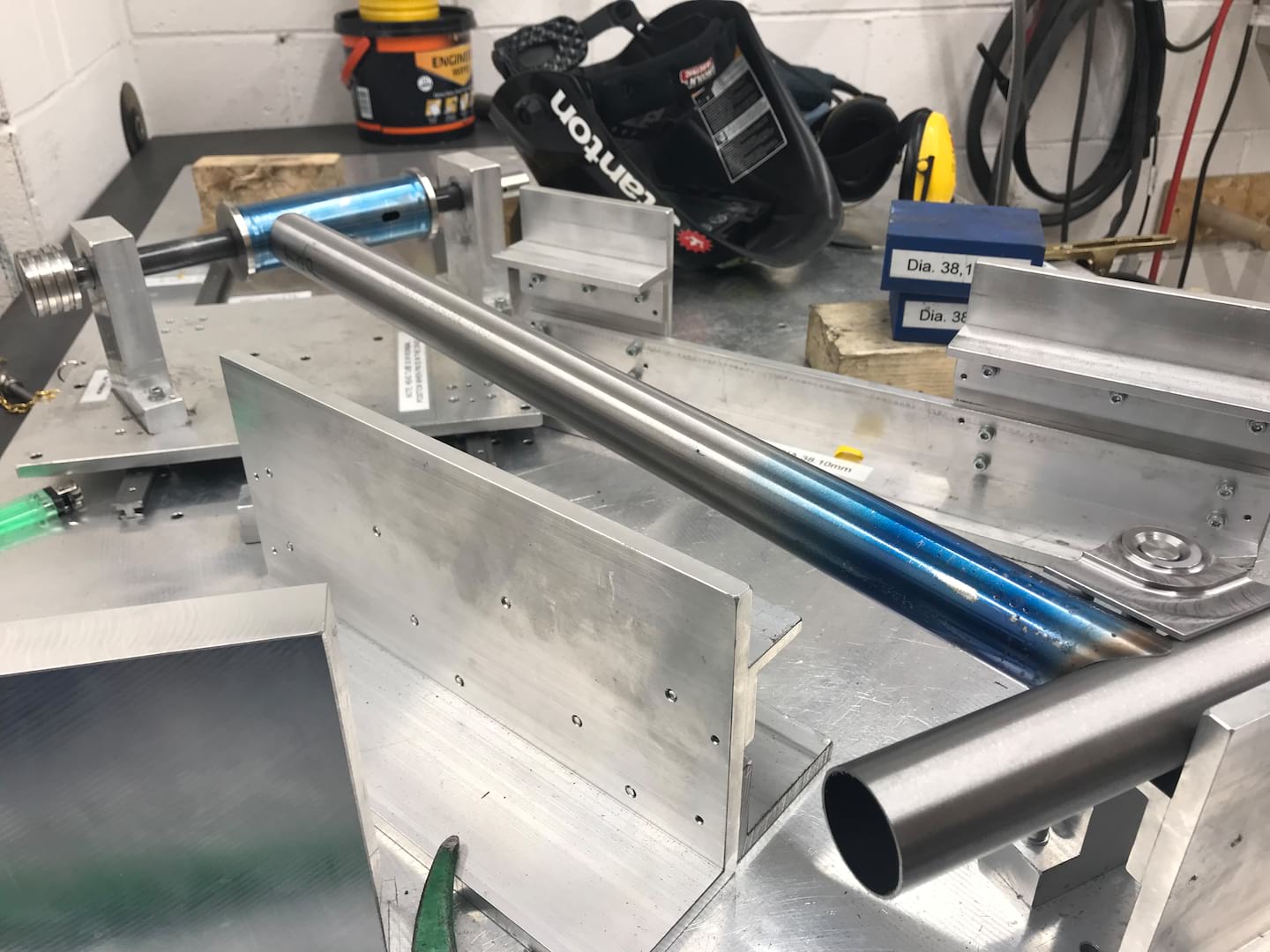

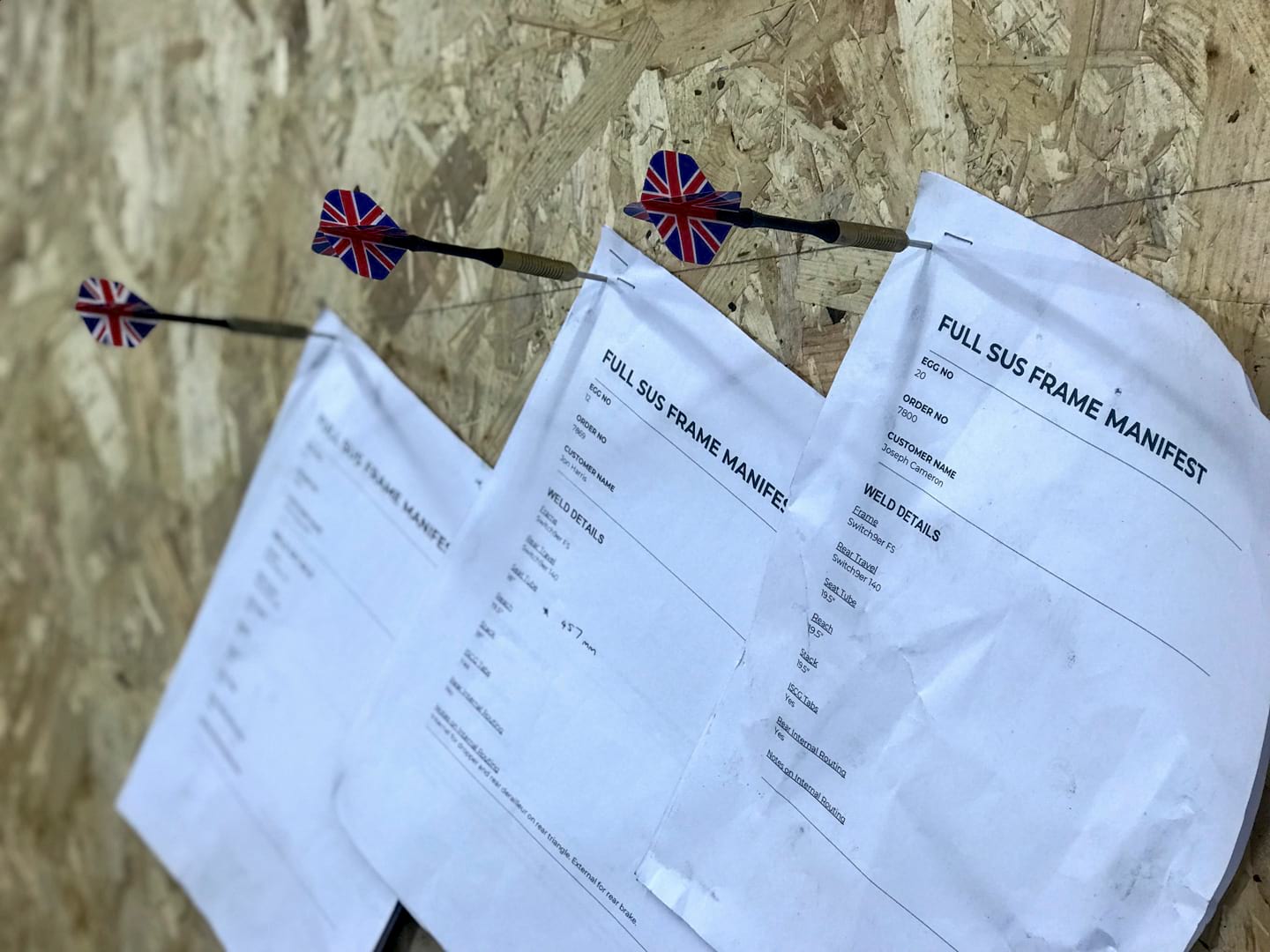

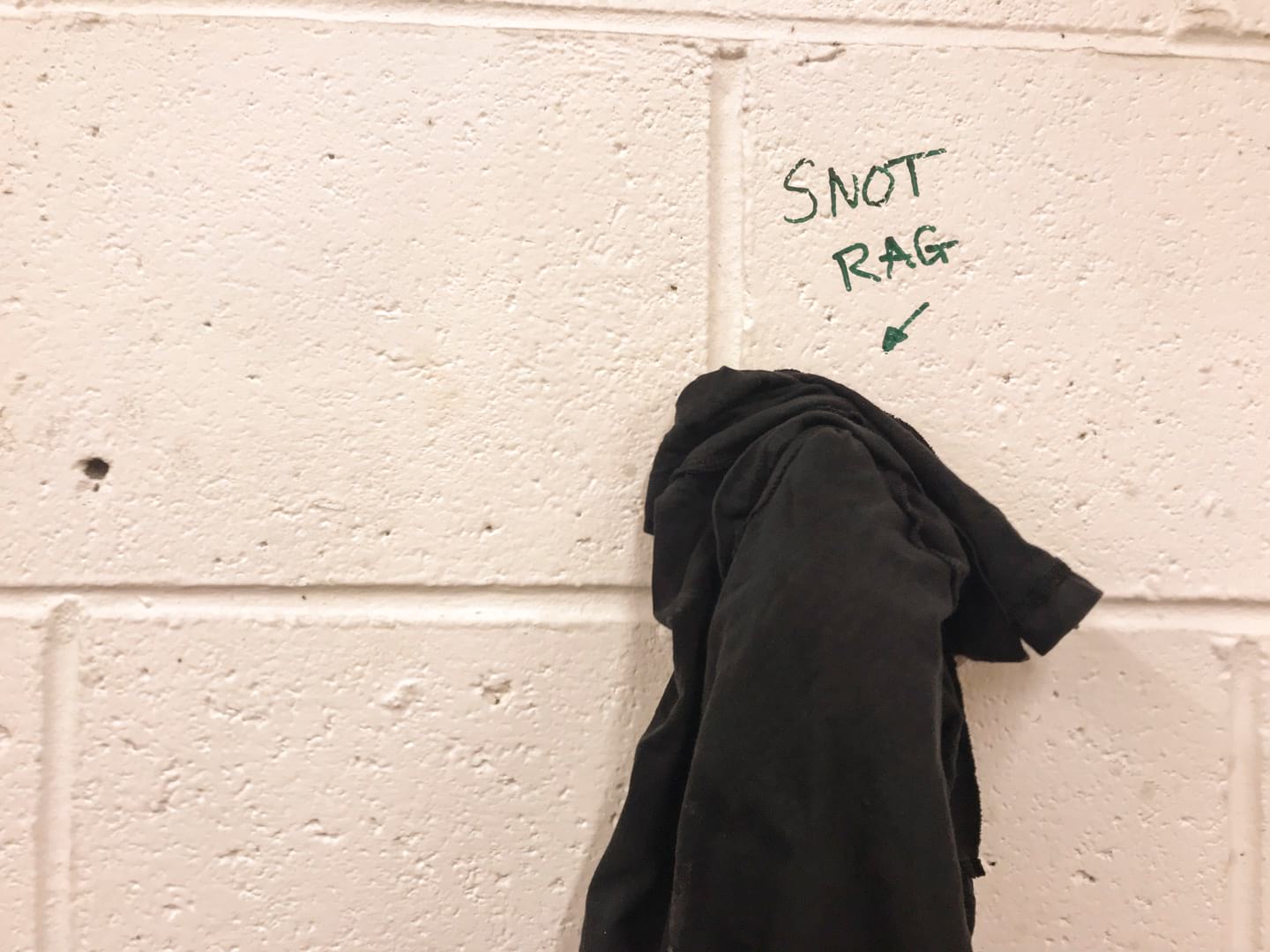

There are two key strands in the production process – the hardtails, and the full suspension bikes. They’ve invested in a machine – ‘the Marchetti’ – that will enable them to chop and mitre the tubes for hardtails at the rate required to keep up with production and deliver the scale needed to meet the price point, and they’ll be welded on site in a new hardtail welding room. The full suspension bikes will continue to be made as they are at present – with the front triangles cut to order and welded by hand in the existing welding space. Somewhere in their business plan it notes that a key challenge is in beating the perception of UK manufacturing: ‘expensive and shit’. Dan repeatedly emphasises that both processes will deliver bikes that are built to the same quality standards as any big factory produced bike. The Stanton HQ might have the friendly atmosphere of the clubhouse of some steam train enthusiasts, but it’s no hobby. It’s just a very small factory.

Taking the construction in house and keeping it in the UK reduces lead times. It helps keep the effect of currency fluctuations down, as you’re not working now with something you paid for a year ago. Waste is reduced by taking away the prediction of quantities and shipping container volume requirements, so Dan can sell the bikes at a stable price without needing to put discounts on ‘old’ frames. It all seems to make sense from a business perspective, but Dan says there are benefits to the customer too.

As things stand, you can take a bit of a pick and mix approach to the geometry of the full suspension bikes, with riders being able to choose different seat tube lengths, reach and stack to suit their needs. Bringing the hardtail production in house will allow the same customisation to be applied to these frames, giving customers more choice.

The big change is in the introduction of the Marchetti machine, but it’s not just the frame building that takes place at Stanton HQ. Frames are also painted on site, and as well choosing from standard or custom colours, for a fee you can choose any RAL colour you like. You have have your front triangle one colour, your rear another, and your decals another colour too. Not that we’d necessarily recommend that – the finished result might be less than pretty, but we’d be happy to be proven wrong.

Together Through Life

So you’ve got your pick ‘n’ mix geometry, and your bike painted in three colours. Whoop! Now you can ride off into the sunset. But wait. That orange/yellow/purple combo you chose is wearing a bit thin. Time for a new bike? Not necessarily so. In the time I’m at Stanton HQ it becomes apparent that there are big Stanton fans out there, who own more than one Stanton and come back for another (and even get to be part of the Stanton Owners’ Club, complete with ride outs and hoodies). However, Dan doesn’t want you to have to buy a whole new bike just because you’re tired of the colour, or want to change your wheel size. Send your bike back and you can have your bike stripped and repainted. You can buy new linkages to change the travel of your bike as you change riding styles or preferences, and if you want to swap your rear triangle for something in, say, carbon, eventually you’ll be able to do that too. Dan designs the components to be compatible – ‘hop up-able’ – so you can upgrade your Stanton rather than buying a whole new one.

It’s a level of sustainability that runs through Dan’s aspirations for the company. His vision for the future involves turning a farm into a factory, complete with family campsite, test fleet and bike trails. It may sound like some kind of hippie utopia, but he wants to take on the big corporates. He wants to grow the business and take on the big name brands out there, but he wants to do so in a way that’s economically sound and retains the family feel of the Stanton brand.

Not only that, but he wants to share all that he’s learnt in establishing Stanton with others who want to design a bike. With everything available in house – from CAD skills right through the build and on to marketing – Dan wants to offer the Stanton services to other would-be-Dans to take their designs from paper to trail. He’s already talking to other brands about providing services to them, such as painting, because they’re seeing the benefit of having a more local production line too. In years gone by we’ve seen Cotic try to bring their manufacturing back into the UK – and abandon those plans. But perhaps times are changing, with Dan’s model being not too dissimilar to that of Five Land bikes, who are now working with Cotic, Swarf and others to produce UK-made bikes.

Modern Times

It seems to make a lot of sense. Practically, I can see the logic behind it – and it sounds like it should work for both business and customer. Dan has some fancy words to go with the theory, and the carefully laid out business plan complete with infographics and white board with monthly goals and responsibilities for each staff member speak to a level of maturity way beyond your average shed builder. But that doesn’t mean the passion isn’t there. He still wants time to ride bikes and play on them, and he wants you to go out and play too. Only he’d quite like it you were playing on something he’d built – he’s got a farm to buy.

Fills me with great hope the we are going to see a Renaissance in mtb. Great to hear words such as sustainable and economically sound. Its about time Mountain Biking stood up, good on you Stanton. I will never forget cutting a corner in Moab on the porcupine rim (all of five feet) twenty years ago and get ticked off by two local trail (women) for hurting the supposed untouched desert (this is the US thinking big in environment). I’m still gobsmacked today at the total lack of big picture thinking in MTB which the US has led for so long.

This is very encouraging.

The best quality bikes in the world used to be built here and they were built to last forever. Factory refurbishments were common on the better bikes like Sunbeam.

What do we lack now to build a complete British bike? We have frame and component manufacturers, and I think all we lack is tyre, rim, and drivetrain.

How about STW doing a complete British bike project?