I've got the post-winter hibernation urge to do stuff, and part of that is making things. Not sure what yet.

What have you made recently? Post up pics.

primal meatloaf and very spicy bean casserol.

pics when cooked later.

Does software count or do you mean physically?

[edit] actually I misread the OP

Does assembling components class as making something?

can't see software, but if you made some, that's fine with me.

ton - how'd it go on monday?

I made a cheese and onion pie on Sunday but alas I took no photos of it.

I did however make this over Christmas and discovered that my close up eyesight is shot to bits.

you can all think for yourselves: babies, food, software, bike builds, whatever..!

ton - how'd it go on monday?

successfully........ 😀

Ham and crisp sarnie 🙂

successfully........

Are you all better then?

*(stands on chair and) high fives ton*

hope it stays that way and you can get back on that bike..!

Last thing I released was:

[url= http://hatteamcreator.co.uk/ ]http://hatteamcreator.co.uk/[/url]

Probably of no interest to anyone on here! 😆

Harry, for now i am, 50/50 chance of it going wrong again.

consultant could not get to some parts of my aorta.

so fingers crossed........ 😀

Ton, good news then! You feeling positive and fired up?

Making stuff... Just used Sugru to make my mouse more ergonomic (have big hands) and repair an iPhone dock cable.

Happy now.

I know life's not a contest, but NO ONE can beat this:

[url= http://farm6.staticflickr.com/5301/5750703061_c5cc843f83_z.jp g" target="_blank">

[url=  [/url] by [url= http://www.flickr.com/people/7693620@N05/ ]alan cole[/url], on Flickr

[/url] by [url= http://www.flickr.com/people/7693620@N05/ ]alan cole[/url], on Flickr

😉

ourmaninthenorth - Member

*(stands on chair and) high fives ton*hope it stays that way and you can get back on that bike..!

cheers mate, and thanks for asking. i hope you get a good outcome.

Willard

i am mate, got a ride planned for sunday, nice and steady like, and feel 100% better with some good weight loss too.

just made a phone call

earlier I made my legs hurt

Harry, for now i am, 50/50 chance of it going wrong again.

consultant could not get to some parts of my aorta.

Ooh. Let's hope you get to the right side of that 50/50. Enjoy it..!

(Mine's infrequent, so doing nothing specific yet, but will no doubt get lined up for some heart welding some time)

NO ONE can beat this:

100% of OAR-SUM

goon - that detail is magnificent..!

Composter out of an old single bed. Too huge/orsum to photograph

Goon, you are in a different league to me. You were right about the orange decals though. 😐

Got some more examples of your work?

A difference.

😉

I made these last night

[url= http://farm8.staticflickr.com/7053/6816592546_96375fbece_z.jp g" target="_blank">

[url= http://www.flickr.com/photos/mhampshire/6816592546/ ]big old cats eyes[/url] by [url= http://www.flickr.com/people/mhampshire/ ]SoFaKiNg.[/url], on Flickr

Twins!!

I made a bad smell. Sorry 😳

[url= http://farm8.staticflickr.com/7060/6942827295_bc9d9e7122.jp g" target="_blank">

bicycle fabric

I made someone sad.

Now I'm busy making a hash of everything else.

A frikkin laser

I don't know if it counts, but I made this animation of a bean growing:

it all counts.

A mess of the toilet

& later I'll make the wife happy by letting her clean it

ourmaninthenorth: I love my bowsaw!

[url= http://farm4.staticflickr.com/3554/5768910982_dcf994378e.jp g" target="_blank">

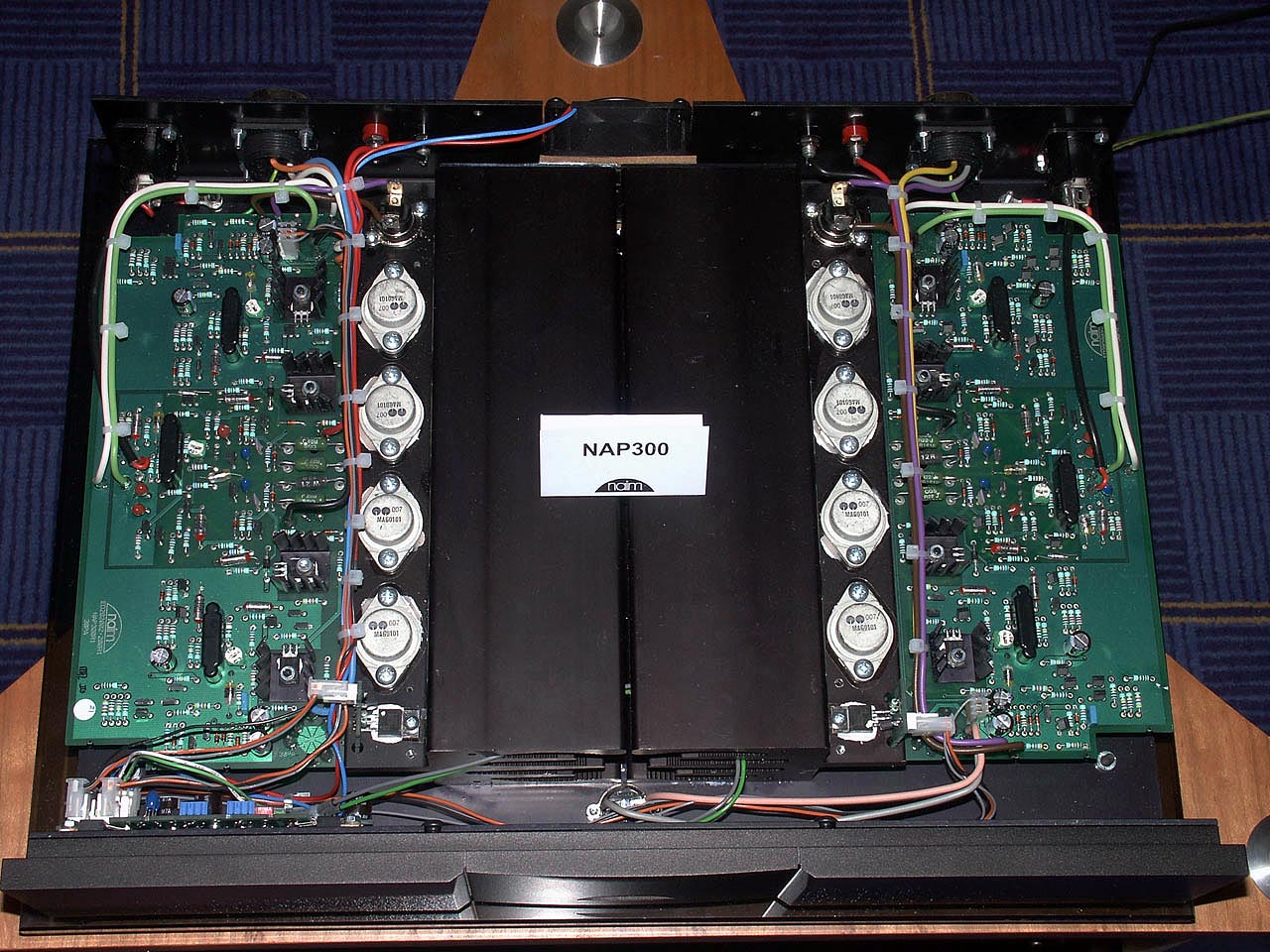

To be fair most of it came pre-built but it was still pretty damn tricky fitting all the gizmoraty as I've come to think of it.

@dazz - classy 🙂

Just made a couple of quid today...

Hope not to make a monkey of myself tomorrow and give it all back

A meths stove out of a Sigg bottle.

People - you make some good stuff..!

Never heard of a nerf gun before. First google search throws up this lunacy...

[url]

Carved a bowl from wood with ...

axe---chisels---knives---sandpaper---wax

[img] http://www.tumblr.com/photo/1280/antsdontsleep/15685225435/3/tumblr_lxnkpkErWb1qk12zz [/img]

I made DavidB some money by buying that book.

last thing I made?

beer. 33x 500ml bottles of 6% ABV pale ale

I made a little sex wee because of beej

Actually this was the last thing i made

I've got into making bread. Proper bread.

I made a gate last year. From wood, not bread.

I also made some students pass their first lot of A level exams. Though they may have helped a bit too.

i steampunkd a couple of nerf guns last night

What sort of paint do you use for that sort of work?

(Only, I have a similar project in the pipeline)

Cougar - Memberi steampunkd a couple of nerf guns last night

What sort of paint do you use for that sort of work?

(Only, I have a similar project in the pipeline)

spray the whole thing black with some games workshop matt black

then humbrol enamels for metalic colours

and games workshop acrylics with water for a wash to make it look grubier

and a light spray varnish from an art shop

you can get a good metalic shine to grunge effect using the humbrol metalcotes, you paint it on then buff it up with a soft cloth (the stuff in the recesses not buffed remains very diffuse and dark), blue acrylic wash works well on top of gunmetal. varnish to finish.

I made a childs day by handing them a sharp knife, some twigs, a bag of marshmallows and a lit kelly kettle...

Shmores allround, while watching the snow settle all around us 8)

I've got a lovely 3rd degree burn from toasting marshmallows.

*is still wanting to be the adopted child of mcmoonter*

I made one hundred pounds by selling my book.

Thanks everyone here who bought it and thanks for anyone who reviewed it.

I've just made it to 8 days without a cigarette.

well done squidlord!!

I've made a few cardigans, a dress for gf, a skirt for me for work. working on another dress atm.

[url= http://farm8.staticflickr.com/7193/6964566957_f8496a633b_z.jp g" target="_blank">

[url= http://www.flickr.com/photos/47638700@N06/6964566957/ ]Untitled[/url] by [url= http://www.flickr.com/people/47638700@N06/ ]jerrypc69[/url], on Flickr .

.

.

.

.

But more importantly I want to see what WCA has made recently .......!!

Kimbers / Klunk > cool, ta for the info.

Last thing I 'made' was either a modded Xbox controller (replaced the worn-out controls) or a couple of Windows Server 2008 servers, but neither really count I guess.

Ebygomm.....I WANT!! Can you buy them?

Rorschach: Not for sale I'm afraid, it's very hard to sell any handmade sort of toy in the UK

ebygomm - that really is very cute. Are you selling that fabric ^^^?

Hard to sell any kind of handmade anything imo.

Anyway I made 3 handbags http://emmyjane-design.blogspot.com/ out of Union Jack fabric.

Oooh good news Ton.

The fabric is for sale at [url= http://www.spoonflower.com/fabric/995303 ]Spoonflower[/url]

I'm just proofing it at a slightly smaller scale which I think is a bit more useable though

I've made lots of sock animals but the tortoise/hare is my first reversible one

[url= http://farm8.staticflickr.com/7186/6965251239_587ebf6c7b.jp g" target="_blank">