Home › Forums › Bike Forum › Epic carbon fork fail.!

- This topic has 73 replies, 44 voices, and was last updated 13 years ago by Klunk.

-

Epic carbon fork fail.!

-

WaderiderFree MemberPosted 13 years ago

Thread resurrection.

Scientific detail – since I last visited this thread I have seen a BMC road carbon road bike with a fracture at the seattube/seat stay junction, and a Yeti ARS five with a broken swing arm.

Just keeping you up to date. I may be back. No failures noted in other materials.

hugorFree MemberPosted 13 years agoScientific detail – since I last visited this thread I have seen a BMC road carbon road bike with a fracture at the seattube/seat stay junction, and a Yeti ARS five with a broken swing arm.

Listen everybody knows that they build rocketships and jet aeroplanes out of carbon.

There’s only 2 possibilities here – either you’re lying or these riders were travelling faster than both of these.atlazFree MemberPosted 13 years agoI’ve seen a titanium frame cracked through on a ride in Swinley. Does that make all titanium suspect?

TheFlyingOxFull MemberPosted 13 years agoI reckon so. I’ve seen my mate’s Ti frame snap clean in two on the seatstay & chainstay. Lethal material for a frame if you ask me. 🙄

nicko74Full MemberPosted 13 years agoThat squirrel really had a death wish. The worrying thing is that squirrels at Swinley seem to line up to do exactly that!

My mate did similar with a pigeon in London. Nobody cared – pigeons are foul, fact!

13thfloormonkFull MemberPosted 13 years agoListen everybody knows that they build rocketships and jet aeroplanes out of carbon.

There’s only 2 possibilities here – either you’re lying or these riders were travelling faster than both of these.Genius. I wish I worked in a bike shop again just so I could use this line to deny EVERY warranty that came along 😀

oldgitFree MemberPosted 13 years agoBike number six to go in the last two months. This time a Cube near the seatpost. Cube are replacing without the slightest fuss.

Pinarello FP x 2

Time x 1

Planet X x 1

Boardman x 1

Cube x 1donsimonFree MemberPosted 13 years agoBike number six to go in the last two months.

😯

What are you doing to them?

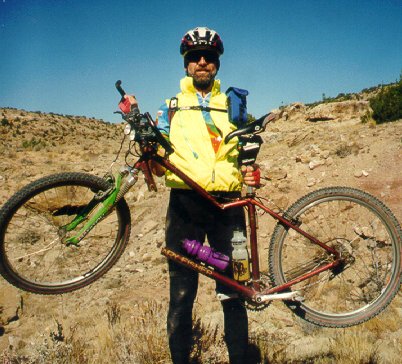

In the last 15 years I’ve had 5 bikes and still run 3 of them. The 15 yr old GT Avalanche looks like it has a stress fracture and my Dave Quinn frame gave up after a high speed off where the front wheel got caught in a drain that crossed the road and stopped instantly throwing me about 10-15m down the road.

http://www.flickr.com/photos/think180/3217750376/sizes/m/in/set-72157600206274323/%5B/url%5D

http://www.flickr.com/photos/think180/3216918939/sizes/m/in/set-72157600206274323/%5B/url%5DdonsimonFree MemberPosted 13 years agoAh they’re not mine, but they belong to fellow club members.

That’s alright then, nothing to worry about.

boxfishFree MemberPosted 13 years agoI have ridden aluminium, steel & titanium hardtail frames. They have all cracked. I have no reason to believe that a carbon frame would behave any differently!

MacavityFree MemberPosted 13 years agoDon Ferris of Anvil said on:

http://www.frameforum.org/forum2/index.php?showtopic=2317

That: “Even the largest and most efficient cargo aircraft have a payload ratio of less than 4 to 1, with most being less than 3 to 1. In other words, for one pound of aircraft weight, they can carry 3 pounds of payload. A 20 pound road bike with only a 150 pound rider has a load carrying ratio of 8.5 to 1. Put a 200-pounder on that bike and it grows to 11 to 1. Put that 200 pounder on a 40-pound DH rig designed for 9-g loads, and you’re still at 6 to 1. No the best way to compare stresses obviously, but it does put into perspective how bicycle frames are exceptionally stressed for their mass.”Similar story applies to CFRP, if used on aeroplanes; there is a system of classification of parts on planes eg critical parts, sensitive part. Sensitive parts, if they fail, will cause a drop in aircraft performance in flight eg speed, fuel consumption etc, Critical parts, if they fail, will lead to the plane falling out of the sky. CFRP is not first choice for critical parts.

boriselbrusFull MemberPosted 13 years agoSimilar story applies to CFRP, if used on aeroplanes; there is a system of classification of parts on planes eg critical parts, sensitive part. Sensitive parts, if they fail, will cause a drop in aircraft performance in flight eg speed, fuel consumption etc, Critical parts, if they fail, will lead to the plane falling out of the sky. CFRP is not first choice for critical parts

But isn’t the rear stabiliser and rudder on the A380 all carbon? I’d say that was a critical part… Certainly wouldn’t want to be in one if it broke off!

FWIW I have no issues with carbon bike bits. I’ve seen catastrphic failures in all materials and I’ve seen carbon bend without failure. After all the chainstays on a Cannondale Scalpal are carbon and designed to bend.

shedfullFree MemberPosted 13 years agoWas the hub still clamped in the dropouts after the crash and can we see a pic of the wheel?

cynic-alFree MemberPosted 13 years agoNo the best way to compare stresses obviously,

The most important part of that paragraph.

aracerFree MemberPosted 13 years agoThe

most importantonly useful part of that paragraph.FTFY

Critical parts, if they fail, will lead to the plane falling out of the sky. CFRP is not first choice for critical parts

I’d recommend not flying on a 787 or an A380 (or indeed any future aircraft from Airbus or Boeing) – carbon fibre appears to be the first choice for most critical parts on both of those. Or does some random punter on a cycling internet forum know better than Boeing/Airbus engineers?

ampthillFull MemberPosted 13 years agoDo you think A380 etc. get leant against lammp posts and chucked in the back of transists?

Singlespeed_ShepFree MemberPosted 13 years agoCarbon Fork – Fine

Aluminium Frame – Goosed

Brick Wall – ScuffedoldgitFree MemberPosted 13 years agoI think the issue (if I have one) is that all the carbon I see breaking is ‘just’ happening. They’ve not been in crashes, just riding and racing road. The latest, the Cube is only two months old.

Whilst I’ve broken three steel frames (a hat trick, MTB/crosser/road bike) they’ve all hit something.

I’ve yet to see a steel or aluminium frame just break up on it’s own.Singlespeed_ShepFree MemberPosted 13 years agoOnce you’ve worked in a bike shop or really looked into warranty claims you realise that 99% of broken parts are broken from “just riding along and then…..”

I was just riding along and my fork just snapped 🙄

Hitting a pot hole at speed is going to do some serious damage to any ROAD bike,

mcbooFree MemberPosted 13 years agoI’ve only ever broken one frame, a carbon Scott Genius which went right behind the bottom bracket where they’d stupidly designed it with two little carbon lugs connecting to the rear end. My Mk1 Ti456 is still going but I’m waiting for it to snap at the chain stay like all those other pre-brace models.

I dont really have a point, beyond if you weigh 85kg++ and ride a bike (badly) that isnt the last word in design perfection its gonna break some day.

I was just riding along when the Scott broke. Bike of the Year 2005 too.

KINGTUTFree MemberPosted 13 years agooldgit – Member

Bike number six to go in the last two months. This time a Cube near the seatpost. Cube are replacing without the slightest fuss.

Pinarello FP x 2

Time x 1

Planet X x 1

Boardman x 1

Cube x 1You don’t know if your PX is broken though do you?

njee20Free MemberPosted 13 years agoIn fact, 100% of the evidence says it’s not, and you still keep suggesting it is, or is this a different one? Send it to me, I will ride it. If it’s broken in 6 months you can have it back, if not then it’s mine to keep, seems fair!

Anything brakes, anything made cheaply is more likely to break than a well made product (that’s not necessarily directly proportional to cost), what it’s made of is irrelevant. Carbon can crack and show signs of failure, alu can just fail. To say that you only get ‘JRA’ failures with carbon is ridiculous. The number of warranty carbon frames I dealt with at the LBS was in single figures, we had a Spark that cracked on the aluminium shock mount, and an OCLV frame where the bonded alu sleeve for the BB came out. A couple of S-Works frames with cracked alu swingarms too. Actual failures of carbon frames were incredibly rare.

oldgitFree MemberPosted 13 years agoNot for certain. Obviously I now have what appear to be cracks in both chainstays.

I have ridden it since, and seemed well until I went uphill. Then it started to flex so badly the rear tyre rubbed the stays each side as I put the pressure on.

I was out that day with someone who says he can sort it.FraserHughesFree MemberPosted 13 years agoTo add another slant to this, I’ve bent(!) a carbon seatpost and snapped spectacularly a set of Alu bars….

MacavityFree MemberPosted 13 years agoNot all CFRP (Carbon Fibre Reinforced Polymer) is the same.

Carbon fibre without the polymer (plastic) is just string.

There are different types of carbon fibre as well as different types of plastic.

KlunkFree MemberPosted 13 years agoDidn’t know Chuck Norris rode mountain bikes

he doesn’t he sits on it and the trail moves under him.

The topic ‘Epic carbon fork fail.!’ is closed to new replies.