… Canyon flat pedals, Thok 3D-printed e-bike, HUnt XC Wide Wheelset. Here’s a compendium of the more interesting things to arrive in our Inbox this week.

Commençal ‘launch hype’:

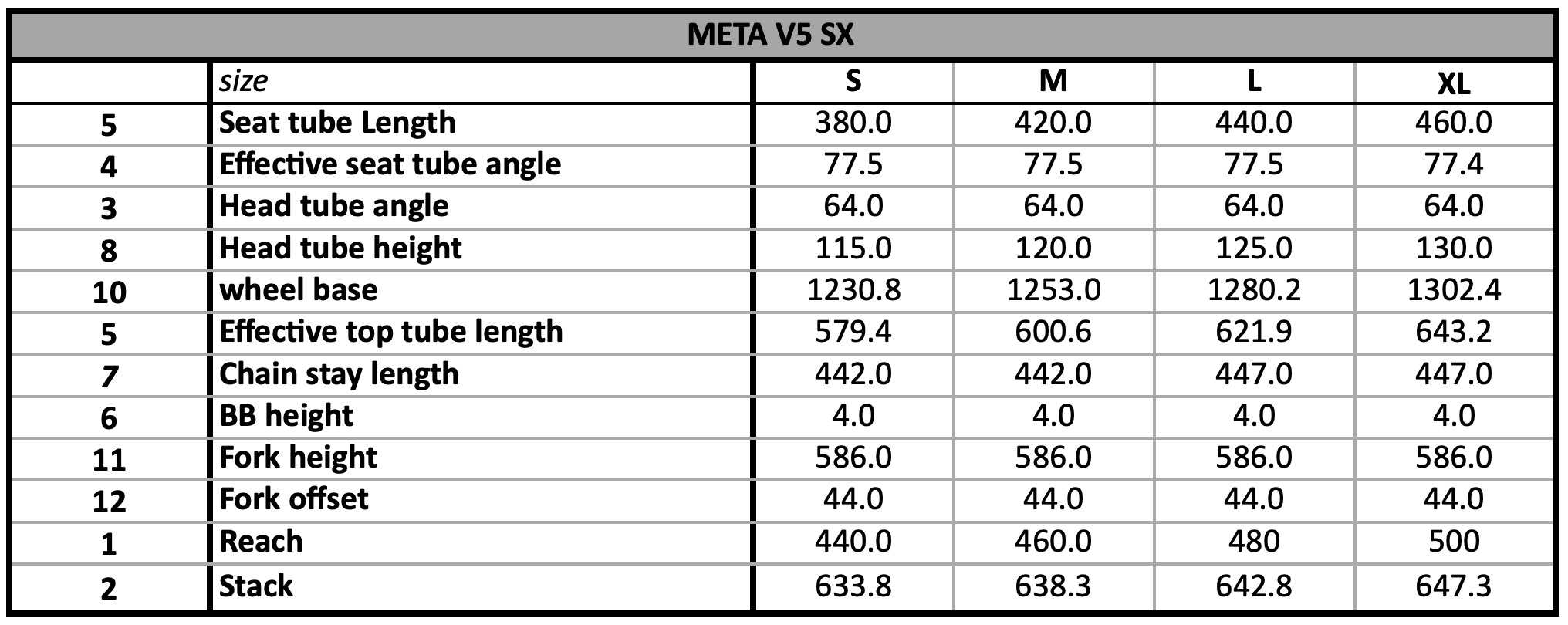

Commençal META SX V5

Canyon press release:

DEVELOPED WITH THE PRO’S: CANYON UNVEIL HIGH-END MTB PERFORMANCE FLAT PEDALS

With two more pedal designs arriving later this year

Ask any trail rider and they’ll tell you – when it’s time to go full send, a good pair of flat pedals can make the difference between feeling firmly planted on your bike and feeling like you’re holding on for dear life. So when it came to Canyon’s debut in the world of flat MTB pedals, there were no half measures. The goal was to make the best pedals on the trail .

With class-leading grip levels, one of the largest surface areas you’ll find in any MTB pedal, and a huge 200 kg maximum load all in a sleek light alloy package.

Now, they’re here. More than two years in the making, tested and developed in collaboration with Canyon’s freeride and downhill pros. Hitting the sweet spot of grip, durability, and stability, Canyon Performance MTB Flat Pedals have arrived. And they’re ready to get rowdy.

Tested by the best

To create the best parts, you need input from the best riders. And Canyon’s Performance MTB Flat Pedals are a product of intense collaboration between Canyon’s own product development team and roster of pro athletes and gravity riders.

And what a result. Uniting a slew of top-end features and premium materials with Canyon’s unmistakeable style, and you know you’ve got a properly serious piece of kit on your hands.

Canyon Product Manager Johannes Wetzel sheds light on the pro-driven design process: “When you’re pushing the boundaries of design and development, you need those invaluable insights that you only get from riders who’re capable of pushing things to the absolute limits and beyond. So of course, we were delighted to work with our athletes on these pedals. Right from the start, they helped us identify precisely what makes the perfect pedal – the ideal balance of grip, toughness, lightness, and durability. And then, when it came down to actually building them, they provided real, actionable input that we fed directly back into the design. And we’re absolutely stoked with the result.”

Canyon Performance MTB Flat Pedals – key features

- An ultra-planted, stable feel. Specifically requested by Canyon’s pro riders, the pedals have a bi-directional concave profile both from front to back, and from side to side. This creates a bowl shape keeping your feet securely in place, so you feel ‘inside’ the pedal rather than just on top. All by using a milled axle design and varied pin heights.

- Sizes for all riders. Choose between shoe size 36-42 or 43-48.

- Pick your style. Available in stealthy black or flash white raw.

- High-grade materials and bearings. An alloy body combined with structural steel axles and sealed bearings ensure long-term durability and race-ready lightness.

- Enhanced grip. With 10 replaceable pins on each side, plant your feet with confidence on the most techy terrain – it almost feels like you’re clipped in. In the name of complete adjustability, Canyon will offer aftermarket pin kits (spare pins and longer pins) soon after launch.

- Thoughtful extras. The edges are specially shaped to slide off rocks, there’s extra embossed stripes for more grip, and they’re easy to mount too using 8 mm (smaller pedal)/6 mm (larger pedal) hex keys.

- Maintenance-friendly. After a punishing season in the slop and the slime, the pedal bearings are serviceable, which will keep your pedals moving freely. To make the job easy, Canyon will launch a service kit, including new bearings, seals, dust caps and the corresponding tools.

Coming soon: two Canyon composite pedal designs

Later this year, Canyon’s flagship pedal will be joined by two further designs. The Canyon MTB Flat Pedal will take all the style of the alloy MTB Performance Flat Pedal and make it available in a more accessible package. Manufactured using injected reinforced nylon composite, with high-quality CrMo axles and sealed bearing systems these pedals truly punch above their weight in terms of performance and durability.

It’s not just about MTB. Exuding sleek city chic, Canyon Urban Flat Pedals are designed to match the look of Canyon’s stunning beautifully urban bike range. And like Canyon’s urban bikes, they’re also wonderfully practical too, with reflective strips, optional branded Canyon plates, and a grainy surface for enhanced friction – no matter the weather or your choice of footwear , these pedals keep your feet firmly planted so you can style it out up town, downtown or around town.

Canyon’s Performance MTB Flat Pedals are available from 28 June at €99.95

Deviate Cycles press release:

Potentially The Most Exclusive Mountain Bike In The World

Artist Edition Deviate Claymore

This is our latest project showcasing our hand-painted Claymore frame by Scottish artist Douglas Roulston. The piece represents the humble beginnings of Deviate cycles as it depicts numerous features of the Cairngorms where Deviate was conceived. Namely, the Green Loch and the Caledonian forests to name a few. As well as being a completely bespoke hand painted frame with a story behind it boasting gold leaf decals on the frame and fork, with a gold leaf spring too. The build itself is equally as special, we aimed to get the best of the best in the component department whilst still allowing it to work well with the frame design. “To ride or not to ride?” We feel like this would be a good talking point for the mountain bike community.

We have also made a video explaining the story behind the bike and how it was painted which can be seen here: https://www.youtube.com/watch?v=L1nLrf5XIC0

We also have a deep dive into the artist Douglas Roulston here.

And an additional blog detailing the ins-and-outs of this project on our website here.

Ibis Cycles press release:

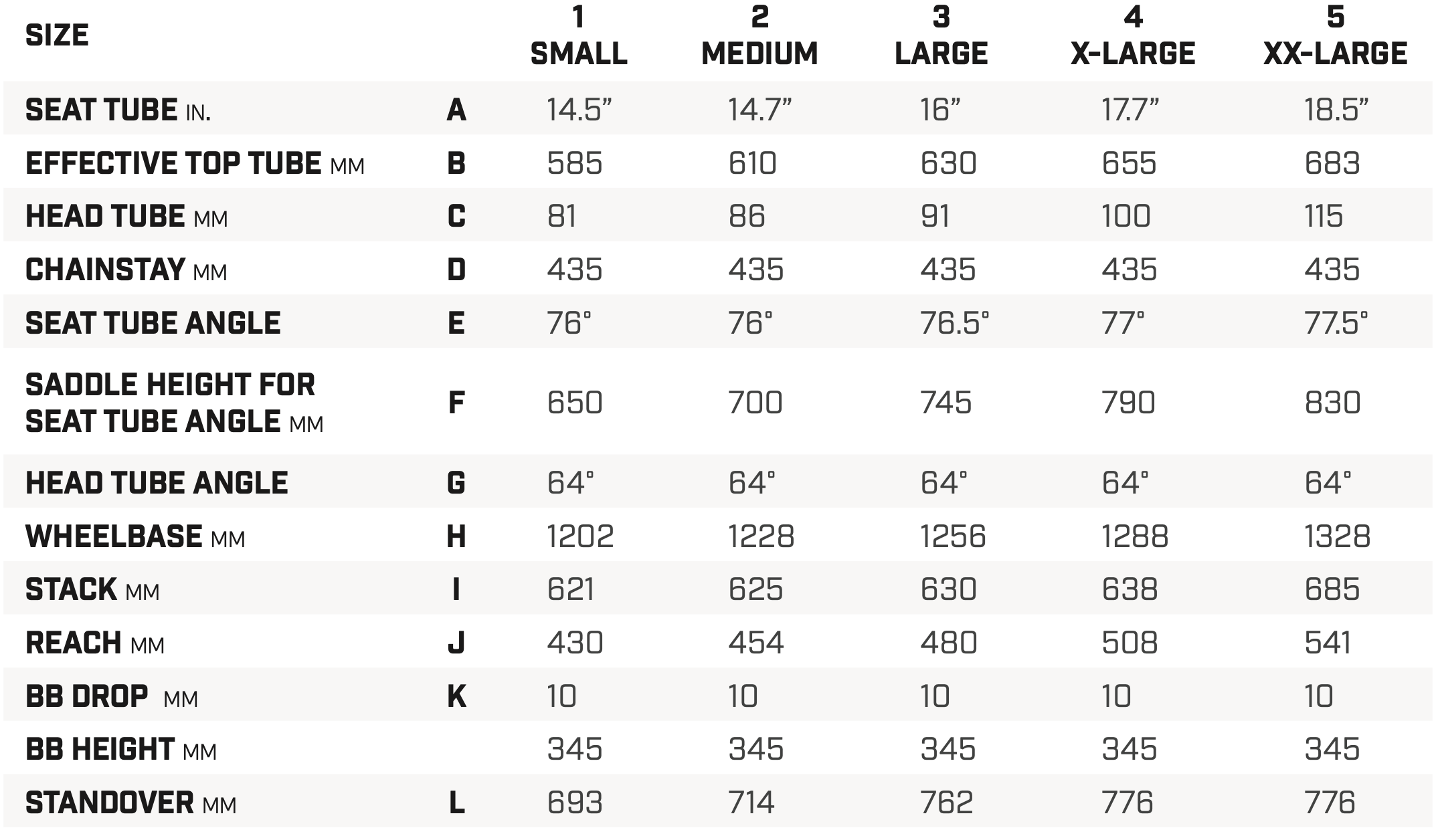

Introducing the Evolution of Enduro Riding – Ibis HD6

Introducing the HD6, the evolution of one of the most successful enduro bikes in history. Designed with input from our Enduro World Cup team and building upon our award-winning Ripmo and HD lines, the HD6 features increased travel, a completely redesigned suspension layout, and mixed wheels.

dw link

With 180mm of travel and a 29” wheel up front the HD6 gives the confidence to charge into the rough. The 27.5” wheel out back gives you a bit more room as the 165mm of travel deals with the consequences. The all new suspension layout is progressive enough to be sensitive off the top, yet supportive enough for the biggest hits. It is also compatible with all coil shocks, for those longer race stages that can tax air shock performance.

The suspension layout may be new, but it’s still dw-Link. The inherent efficiency means you don’t need an overdamped shock to climb well. Less shock damping allows the wheels to stay planted on the ground, providing more traction and that hover-bike feel that our frames are known for. The HD6 climbs with a finesse that defies its enduro race pedigree.

Features

- 180MM front /165MM rear travel

- 29” front / 27.5” rear wheel size

- Laser etched torque specs on the hardware

- Clearance for 2.5” tires and a 26 oz bottle

- Frame weight under 6 lbs without shock

- Internal cable routing in front and rear triangles

- Super-quiet chainstay protector

- Super low maintenance lower link bushing design

- dw-link suspension layout, compatible with all coil shocks

- Top tube accessory mounts and porkchop bag compatibility

- 5 numbered sizes to reduce gaps between them

- Low standovers and uninterrupted seat tubes for long dropper posts

- 34.9MM seat tube ID for stiffness and durability with droppers over 200MM

Thok press release:

THOK E-Bikes builds first 3D-printed rideable prototype of full-suspended E-MTB

THOK E-Bikes builds first rideable prototype of full suspended E-MTB made with 3D-printed aluminium technology

- From this model will be born a light e-mtb equipped with the latest Bosch SX motor

- The prototype was exhibited at Eurobike

This year, at Eurobike, THOK E-Bikes exhibited a rideable aluminium prototype made using a 3D printing process.

While some bikes with similar technology had already been experimented with in the past, this is the first time ever that a fully rideable prototype of a full-suspension E-MTB has been revealed. This includes the right weight, stiffness and flexibility.

The novelty is, that not only is the development technology an absolute worldís first for this type of project, but the final product will also be something never seen before in THOK’s catalogue: a light-E-MTB, equipped with the brand new Bosch SX motor and the possibility of choosing between several battery capacities to better adapt to the biker’s needs.

A moulded but perfectly rideable prototype

ìTHOK Project P4î (P4 is the abbreviation pending the bike’s final shape and name) is the embryo of what it will become, presumably in 2024, THOK’s first ‘lightweight’. Development is underway, with testing on the technical trails of Finale Ligure, currently using the very frame which was exhibited at Eurobike.

It is in fact, and this is one of the big innovations, a perfectly rideable prototype, on which realistic tests are possible.

None of this would be conceivable with traditional polyurethane or PC-ABS models.

Aluminium printing replicates carbon fibre shapes

Most probably the final bicycle will be made of carbon fibre, but making prototypes with this material would be time-consuming and expensive. 3D printing technology therefore uses other materials. In this case, an aluminium and silicon powder, which is solidified using a laser beam. The structure is honeycombed to reduce weight.

THOK’s prototype consists of six 3D-printed pieces, which are then welded together. The resulting product is tested on different types of terrain, generally medium to high level All-Mountain tracks. With this technology, everything imagined in carbon can be prototyped in aluminium.

THOK’s light e-bike expected in 2024

3D printing had been used on rigid frames in the road sector, as well as in a couple of tests on shock-absorbing frames without motor and battery components. THOK E-Bikes is the first company in the world to have employed SLM printing for a working full suspended E-MTB.

The THOK Project 4 exhibited at Eurobike is still in the development phase: geometry, battery positioning and technical solutions will be modified before the launch of the new product, which is likely to take place in 2024.

The new e-bike, in addition to marking THOK’s entry into the light E-MTB sector, will use the new Bosch SX motor and will have maximum battery modularity (400 Wh, 500 Wh, 625 Wh, 750 Wh, plus 250 Wh range extender), allowing the rider to customise the length of time in the saddle and the weight of the bike according to his needs.

Hunt Wheels press release:

HUNT launches updated XC Wide Wheelset with new FEA developed rim profiles

Introducing the All-New, Redesigned HUNT XC Wide Wheelset with Front and Rear-Specific, FEA-engineered Alloy Rims.

Key Performance Benefits:

- FEA-optimized front and rear-specific rim profiles (28mm internal front, 26mm internal rear) to achieve optimal front and rear wheel attributes

- Alloy material upgraded to 6069-T6 (69% greater Ultimate Tensile Strength compared to 6061-T6) to offer class-leading impact resistance

- 1,693 gram system weight with increased width and strength over predecessor

- RapidEngage hubset with 6-Pawl 3X2 system offering 5° engagement angle

The Purpose

Engineered, designed, and tested by the company’s UK-based in-house team, HUNT Wheels announced today the all-new HUNT XC Wide alloy wheelset. While the name has remained, the third iteration of the HUNT XC Wide was created from scratch to meet the changing needs of modern XC riders and racers, and developed using cutting-edge FEA modelling techniques along with extensive input from elite cross-country athletes. FEA (Finite Element Analysis) capabilities allow HUNT design engineers to refine the rim extrusion profile in great detail, considering variables such as rim wall and bead thickness, profile radius, and spoke bed reinforcement to design a lightweight rim with the optimal amount of material in key areas to achieve the desired weight, ride quality and durability.

FEA-Optimized Rim Profiles

After approximately 300 hours of FEA modelling per rim, the HUNT team has created unique front and rear-specific rim profiles to achieve the ideal performance attributes for each wheel’s specific role. The XC Wide wheelset boasts a 28mm front rim internal width and 26mm rear rim internal width, dimensions chosen to optimise performance with modern XC tyres ranging from 2.2 to 2.5 inches. The front rim was designed to offer compliance and a wide tire profile for increased traction under hard cornering, while the rear rim was designed to handle a larger share of the rider’s weight and all of the pedal acceleration forces, while withstanding the increased punishment of rock strikes and impacts dealt to the rear of the bike.

Upgraded Alloy

To pack more performance into an already well-regarded HUNT product, the engineering team upgraded the selected alloy material to 6069-T6 alloy, offering a 25% increase in fatigue and impact strength over the 6066-T6 alloy construction of the previous model, and a 69% improvement over 6061-T6 alloys, as used in many other rims on the market. After an extensive engineering process, the wheelset has been thoroughly tested in the HUNT UK lab to verify class-leading impact resistance among the relevant competitor set. The new rims feature work-hardened, shot-peened matte black finish that enhances strength for prolonged life and season-spanning reliability. Laser-etched graphics won’t peel, crack or fade over time.

Fast Engaging Hubs

At the heart of the XC Wide is the engineered RapidEngage freehub, with a 6-pawl, 3X2 alternating system engaging with a 36-tooth drive ring, providing a quick 5° engagement angle. HUNT’s durable H_CERAMIK coating increases hardness and resists cassette gouging when subjected to hard pedal forces. With both boost and standard hub spacing options, the XC Wide is built to withstand season after season of cross-country trails with minimal maintenance. The hubs are easily customisable with optional end caps, providing compatibility with any current standard. The CNC machined 6-bolt disc mounting interface adds versatility to suit all your XC riding and racing needs. The XC Wide wheelset has been built with precision-sealed replaceable cartridge bearings, offering an easy-to-maintain solution without compromising longevity. Fitted with large-diameter ball bearings and dual full-contact rubber seals, these bearings are built to withstand the harshest conditions, ensuring maximum durability and reliability.

Handbuilt, Every Detail Considered

The wheels are hand laced with high-quality J-bend cold-drawn spokes. Both front and rear wheels use 28 Pillar Spokes made from Sandvik T302 (18/10) stainless steel. These are triple-butted (dimensions of 2.0mm-1.6mm-2.0mm, with patented Pillar Spoke Re-enforcement increased diameter of 2.2mm at the spoke head) spokes, offering incredible longevity. Anodised alloy nipples help to reduce the overall weight even further while allowing for stress-free maintenance when needed.

The result is a lightweight yet modern width XC wheelset hitting the scales at just 1693 grams while providing all the strength and durability necessary for your next race, alpine adventure or long-distance epic. As with all HUNT wheels, the new XC Wide is backed by a 3-year warranty, 60-day ride & return policy, best-in-class rider support, and arrives pre-taped and with valves for easy out-of-the-box tubeless set-up.

HUNT Race XC Wide (V3) specifications

- Rims: 28mm internal width at the front, 26mm internal width at the rear. Constructed from 6069 T6 alloy. Tubeless-ready with included rim tape and valves. Matt black work-hardened shot-peened finish with laser-etched graphics for superior durability.

- Axles: Boost – 148x12mm (Rear) with 110x15mm (Front). 141x9mm (Rear) QR with 110x9mm (Front) QR adapters and Rock Shox Torque Caps available.

- Spokes: J-bend cold drawn for ease of replacement. 28 spoke count for both front and rear. Pillar Spokes made from Sandvik T302 (18/10) stainless steel. Triple butted 2.0-1.6-2.0 (2.2 at the head for patented Pillar Spoke Re-enforcement). Black stainless treatment.

- Nipples: Hard-anodised alloy for weight reduction and strength. Square body for external adjustment and hex head for easy internal adjustment/tensioning. Long 14mm thread for durability. 14 gauge.

- Front Hub: Engineered with durable bearings and 7075-T6 series alloy axles for increased stiffness, performance, and durability.

- Rear Hub: Extruded and CNC machined 6066-T6 heat-treated aluminium alloy hub body. Available in 148x12mm or 142x12mm spacing. Features H_CERAMIK freehub body reinforcement coating for excellent durability and protection against cassette sprocket damage. Boost QR skewers not supplied. 6 pawl, 3×2, with 36 tooth RapidEngage freehub with an engagement angle of just 5 degrees. Oversized 7075-T6 heat-treated aluminium axles.

- Bearings: Sealed replaceable cartridge bearings with free-flowing, large-diameter ball bearings for durability and low rolling resistance.

- Tyre Width: Suitable for tyres between 1.6in – 2.6in but optimized for tyres between 2.2in -2.4in.

- Size: Available in 29in only.

- Weight: 1693g.

- Price: £379 | $479 | €499