Fibrax is a name that many British mountain bikers will be familiar with, but far less of us are aware of the full story. And that’s a shame, because it’s a fascinating story. Part of this comes down to marketing, which Fibrax doesn’t really do a whole lot of. And that’s because primarily, Fibrax is a manufacturer at its core.

During the London Bike Show, we had the chance to chat with the crew from Fibrax to learn more about its range of products, but to also learn more about where the brand has come from, and what it’s doing differently to the rest of the industry.

But first, a brief history lesson. The company first launched in 1902. Yes that’s right, over a hundred years ago. Fibrax started out making parts for bicycles, because at the turn of the 20th century, bikes were kinda where it was at. Then the combustion engine and the car came along, and so Fibrax adapted to start making bits for the automotive industry. Things like brake pads, disc rotors, rubber door seals, grommets – all kinds of little problem-solving things.

These days, Fibrax still manufacturers for both the bike and auto industries. However, about 99% of Fibrax’s business is in the automotive side, where it produces parts for the likes of Land Rover, Bentley, Jagura & McLaren. That might be why the company’s story isn’t so well known in the mountain bike world, because most of its time and resources go into producing parts for cars.

As it turns out though, there’s plenty to get excited about with Fibrax if you’re a home mechanic or simply a budding mountain bike enthusiast. Because everything that Fibrax produces, right down to gear cable ferrules and end caps, are all made right here in the UK in North Wales.

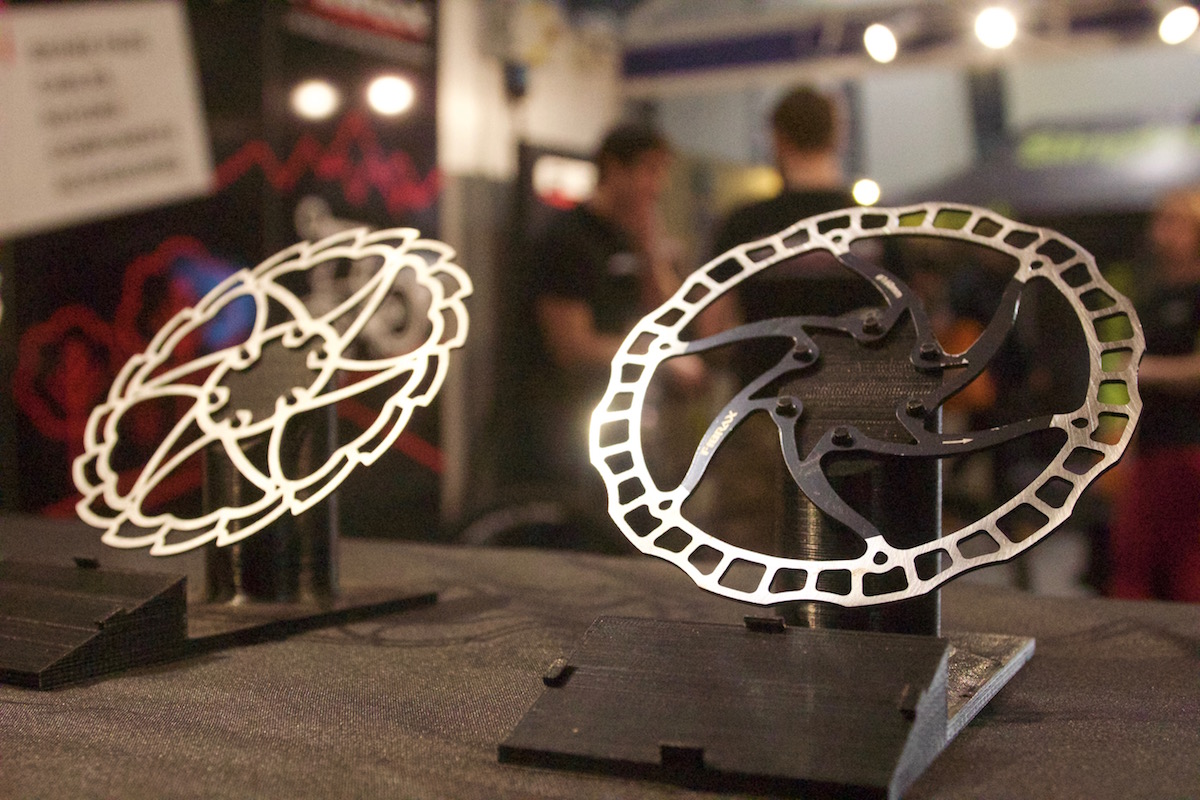

Of course many of these items aren’t sexy. They’re not colourful anodized hubs or pretty handlebars and stems. They’re still essential components though, and typically the unseen ones that we don’t really think about – the ones that make you stop and go. On the stop side of things, Fibrax machines its own stainless steel disc brake rotors (as shown above), and it’ll soon be expanding its lineup in the near future with a completely unique rotor design that will have a clever feature that no one else is producing. Stay tuned for more on that one…

Fibrax also makes disc brake pads, and unlike many of its competitors, it makes these in the UK. There is a huge range of different styles available – from Shimano and SRAM, to Magura and Hayes, to older models like Grimeca and Cannondale – Fibrax pretty much does it all. You can get them in Sintered Metallic or Semi-Metallic pad compounds, and given Fibrax’s experience of working with the likes of McLaren & Jaguar, you can place your bets on the fact that they know a thing or two about high performance braking.

Then there’s all of those tiny components such as cable end caps, ferrules and outer casing – all of which is (you guessed it!), made in the UK. And you can purchase all of those items individually if you’re just working on your own bike at home, or in bulk form if you’re working in a bike shop.

A new product that Fibrax launched at the London Bike Show is the spiral frame protector. A super simple piece of silicone spiral tubing, these are used to wrap around your gear and/or brake cables to provide a barrier between the cable and your frame.

And once in place, the spiral protector offers vibration damping to reduce noise of the cable slapping the frame, while also eliminating the possibility of frame rub and the resulting damage to the paint and frame finish. Incredibly simple, but such a neat and easy way of protecting your bike – and all without having to apply stickers to your frame or removing the cables.

For a closer look at the Fibrax range and a bit of a history lesson on where the brand has come from, make sure you check out the video below that we shot whilst at the London Bike Show. To purchase Fibrax components and to find more information about its enormous range of workshop parts, check out Fibrax.com.

I bought some of those spiral protector things well over a year ago at the NEC cycle show.

I’ve had some on my bike for a while too, not sure who made them

Do they work?

Yes, they work.

Great, I’ll test them out on one of the bikes.

does that mean EBC are telling fibs about their brake pads being 100% made in Bristol….?

To be fair – their web site in one place says ‘EBC pads are 100% made in Bristol’, then on the MTB slide it says made in UK and USA – not sure if that is for the different markets to avoid shipping 1000s of miles, or if some are made in the UK some made in the USA dependant on model.

My point is that the Fibrax line may not be exactly accurate…. ;o)

The rotors look remarkably similar to others that are made overseas?

@sillyoldman – You are spot-on there mate! Fibrax currently uses existing rotor designs (open-mould if you will), but still manufacturers them in the UK. However, Ellis from Fibrax told us that they’re working on their own floating rotor that will be 100% unique to Fibrax, and supposedly quite different from anything else out there. Stay tuned…

@cx_monkey – EBC used to manufacture bicycle disc brake pads in the UK (they make car disc brake pads too). But from what we’re aware of, EBC now makes all of its bicycle disc brake pads in the US, while the automotive side still has UK production.