A week or two ago, Chipps and Barney went over to Barnoldswick to say hello to the good people at Hope, and to take a look at their new carbon full-suspension concept bike. Firstly, let’s allow our eyes to linger – ‘cos it’s gorgeous:

And it’s really quite special too, because it’s a concept bike, which isn’t destined (in its current form, anyway) for production, and also because Hope can manufacture stuff in house with their quite startling array of very impressive and very noisy, machines. This freedom means that it’s got a plethora of interesting bits and pieces which don’t fit any of the multitudes of so-called standards in use today.

As you can probably tell, it’s a carbon main frame. Hope has recently moved into carbon production, making seatposts and the like – and as the folk there are also dab-hands at machining aluminium, they can make the moulds for the main frame relatively easily. Relatively – it’s still far from an easy task.

But that carbon front end is attached to a beautifully machined aluminium back end – a 4-bar construction arises from machined chainstays, with a Horst link. The seat stays are welded triangular aluminium tubes with machined ends,and there’s an Ohlins shock which gives 160mm of travel.

Things get pretty interesting at the rear axle. Because Hope can make their own hubs, they decided to experiment. So the drive-side has pretty much the same configuration as a regular, BOOSTed rear end (by accident, apparently), but the non-drive side is moved in towards the centre to massively increase clearance and to create a dishless wheel.

Stiffness is boosted by using a 17mm axle, So overall, instead of 148×12 for BOOST, it’s 130×17. Interesting, no? Before you roll your eyes and groan about ‘new standards’ though, I’ll remind you that this is a concept bike – and the purpose of them is to try out new stuff to see if it’ll roll. Not everything you see here will make production (indeed, if anything; let’s not be hasty), but Hope has the capability of making something like this as a testbed for new tech. And that is really pretty cool.

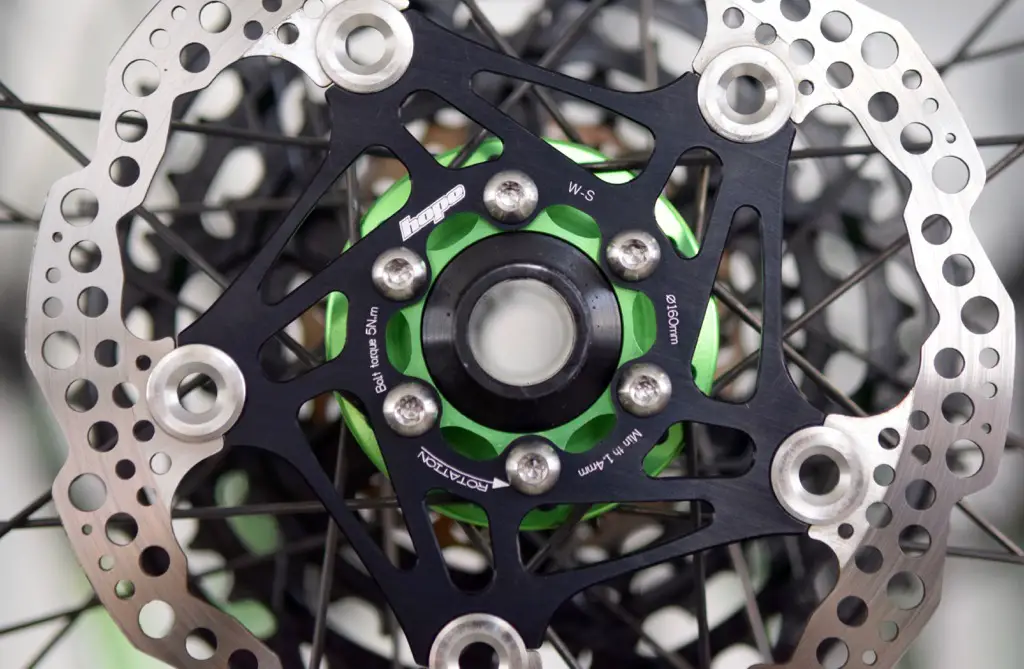

The bike rolls on 27.5 wheels with a Fox 36 up front, and has a 1x drivetrain – a SRAM XX1 rear mech and shifter are mated to (surprise surprise) a Hope chainset and 11 speed cassette. There’s a new type of 3-bolt mount for the chain device, which Hope claim is stiffer, too.

But in a world where ‘concept’ cars too often mean show-queens which can’t actually be driven, the HB.211 has been ridden, hard, already at a variety of races and events, as well as on the local trails. Keep your eyes peeled and you might even see it (or one of its successors) at an event near you…

[fbvideo link=”https://www.facebook.com/singletrackmag/videos/10153808012628612/” width=”650″ height=”400″ onlyvideo=”1″]

Nice that! Not sure we need more standards though.

Almost like you didn’t read the article..

Desire levels rising…

SHUT UP AND TAKE MY MONEY!!!

nice, yeti looking 🙂

I like that dish-less rear wheel, that actually makes sense (unlike a lot of new standards!)

Those machined stays look like a mud trap. I could see that gaining a couple of kilos in winter in this part of the world.

Commits the sin of visible carbon weave but otherwise… cor.

Lovely. Shame that yellow spring makes it look like a Halfords special

want, want want!!!!

It’s lovely.

The weave is presumably visible because the forces and layup haven’t been finalised/optimised – it’s a prototype after all.

Personally I’d happily take it as-is!

Dishless rear hub, they could’ve done that already by spacing flanges on the Pro4 better, at the same time as making sure the diameter was such that wheels used the same size spokes both sides, and front and rear. But they didn’t bother.

3D printer cable guides for the front and zip-ties for the rear end? Fail. Couldve printed some clamp on cable guides for the back at least if they didn’t want to weld them on.

Anyone else think it just looks like an old Remec/Elan with the carbon/alu mix. Retro.

I love the way they are not only experimenting, but also happy to share the ideas at prototype stage. If only the whole industry acted in such an open way.

Curious about the rear shock. Any info?

SHUT UP AND TAKE MY MONEY!!! +1

“I love the way they are not only experimenting, but also happy to share the ideas at prototype stage. If only the whole industry acted in such an open way.” also +1

As far as I know the shock is one of these: https://www.ohlins.com/product/ttx22m/

is disappoint, I was expecting the whole bike to be milled from a single billet of aluminium.

It’s nice. The thing is, if Hope only make parts to fit to other people’s frames then they have to make parts that fit “standards”. If Hope make parts to fit their own frames then they can do what the hell they like. The bike industry is highly standardised – compare to the car industry, where every damn thing is manufacturer-specific. So, yes it’s a prototype and yes they’re having fun and yes there are advantages. But, let’s be careful out there.