- This topic has 71 replies, 25 voices, and was last updated 7 years ago by SammyC.

-

Drivetrain clearance issues doing me nut. Anyone use a Goatlink?

-

kayak23Full MemberPosted 7 years ago

Hello.

Excuse the lengthy post, but bear with me.I’ve got a Production Privee Oka, which I’ve had for only a month or two.

I’m having some issues with the drivetrain that to be honest I’ve not come across before and so wondered if anyone had. For info, I have an XT 10s shifter, SLX 10s mech(brand new med cage), KMC chain 10s, Sunrace 11-42t cassette, Superstar N/W front 30t ring.The frame itself can run either 27.5″ wheels, or 26″ wheels, by way of dedicated dropouts that change the axle position effectively.

Up until this weekend, I have been running my 26″ wheels and using a Shimano XT cassette with a Superstar 40T expander fitted.

Generally speaking, the drivetrain had been running fairly ok, though I was having issues with the chain skipping in the smaller cogs under power.I had been fancying a bigger cog, a 42T and also wanted a smoother transition on the cassette, so, I bought a Sunrace MX3 11-42T cassette which I fitted. Initially it appeared to work very well but then I found I was having more problems with the chain slipping under load in the small cogs. By the way, I also replaced the chain for a new one.

I thought perhaps that my gear hanger might be bent and so I made myself a tool to check and adjust it. With that done I was still having issues with chain slip in the smaller cogs.

I think essentially the problem is that the B-screw wound in to clear the largest cog, was making the distance from the jockey wheel to the smaller cogs too great, too much free chain and not enough chain wrap.I then got myself some 27.5″ wheels(for my big bike) and thought I’d try them on my hardtail, and so I changed the dropouts to the 27.5″-specific ones.

This time it would seem that I have a different problem, in that the distance from the arm on the mech to which the cable is attached is seemingly much smaller and when I change up and down the block, the chain actually hits it and gets jammed. So, I have a new problem, and probably still the old problem but can’t get far enough to ride it to see because this new problem causes the whole drivetrain to jam!I have compared both sets of dropouts and the distance from the centre of the axle to the centre of the mech mount is pretty much identical on both. The problem as I can see it is the tab on the bottom of the hanger which the tab on the mech ‘elbow’ hits against to stop the mech rotating.

If you look at pictures of my mech, you can see the little elbow is going uphill towards the back of the bike thereby bringing the mech closer. If you look at most other bikes, the little elbow is usually pretty much in line with the chainstay. I can’t see how this problem can be gotten around really.It doesn’t make sense to me how the axle to mech mount distance being the same, the problem can be so different on the 650b wheels/dropouts.

Let’s have some pics.

This is the bike the other day with my 26″ wheelset on. You can see that (to me at least) the mech looks unnaturally far back and angled down. To me it should be much more forward, rotated anti-clockwise and down. So it works like that to a point, but I get the chain slip I mentioned and lots of skipping in the smaller cogs.

This is the bike with the 650b wheelset on. You see how that mech elbow is so far angled upwards? That to me is not right, and I think it should be pretty much in the same plane as the ground.

This image shows my problem. The mech arm where the cable attaches is mega close to the cassette and changing gear makes the chain jam against it.

This is a close up of an image I pulled off the PP website showing a Shan I think. It would seem that the elbow on that is at a similar angle.

So this photo pulled off Google images shows a bike with the elbow at what I think is a more normal angle.

This angle has the effect of dropping the mech away from the cassette a little which gives the chain more clearance.

So, I don’t really get what’s happening. If anyone can shed any light or experience on it that’d be grand as it’s driving me nuts.

I think the basic problem is that of the elbow being too high, and so to hopefully solve it I have ordered a Wolftooth Goatlink.

This is supposed to alter the position at which the mech sits and I hope it may help, but otherwise, could Production Privee be making their dropouts wrong? (I have emailed them, no reply yet) I doubt this as I’ve not read about a single problem like this with anyone else’s.

So why would changing the wheels cause this issue? Will a Goatlink help?

If anyone has a bit of a clue what’s occuring, I’d appreciate it.

Cheers.jam-boFull MemberPosted 7 years agoThat mech looks totally wrong at the top pic. The gear outer looks way too short.

What does it look like if you take the chain off and disconnect the outer/inner?

ajantomFull MemberPosted 7 years agoAgreed, outer at rear mech far too short. This is pulling your mech up and back meaning it’s jamming on the cassette.

thegreatapeFree MemberPosted 7 years agoThe mech and the hanger have sticky out bits that meet and limit the forward / anticlockwise rotation of the much. If you take your cable off and loosen the hanger bolt you can move yours forward to the right place. Then sort the cable! You can see the bit on your dropout in the first picture, and here you can see the bit on the mech.

kayak23Full MemberPosted 7 years agoHmmm. The outer was cut to meet the mech, the mech wasn’t moved to meet the outer.

I’m not sure it’s this as I have tried it with the cable disconnected and pushing it by hand and it does the exact same.nicolaisamFree MemberPosted 7 years agoOn most shimano mechs i have fitted the small link sits parallel to the floor. yours seems to be at 45 degrees

kayak23Full MemberPosted 7 years ago@thegreatape, it is in the right place. The mech tab is resting against the tab on the hanger. I’ve tried fitting it with the tab below and it looks like it would work, but obviously then the mech has nothing to stop against and so just rotates and moves.

See the picture of the light blue Shan. The mech is sitting in a similar position.

kayak23Full MemberPosted 7 years agoOn most shimano mechs i have fitted the small link sits parallel to the floor. yours seems to be at 45 degrees

Innit… 😐

But the Shan picture off their website looks similar.. (but presumably works)

thegreatapeFree MemberPosted 7 years agoBut look at your bolts, the last one is up at about 10 o’clock in relation to the first one. In the picture of the Scott it’s more like half eight.

ghostlymachineFree MemberPosted 7 years agoFWIW, who ever put that bike together for their website needs a smack in the chops.

And a copy of the instructions.Might be worth you doing the same. Reading the instructions i mean….

kayak23Full MemberPosted 7 years agoInstructions? I’ve fitted countless mechs to countless bikes over the years and never encountered this problem.

kayak23Full MemberPosted 7 years agothegreatape – Member

But look at your bolts, the last one is up at about 10 o’clock in relation to the first one. In the picture of the Scott it’s more like half eight.I know…. That’s why I put the contrasting pictures up.

thegreatapeFree MemberPosted 7 years agoIt’s odd. Have you got a picture of your dropout without the mech on?

somafunkFull MemberPosted 7 years agoAn SLX M675 med cage mech will work on a 1x 11-42 drivetrain so that part is fine, what looks very odd in your pic is the mech drop link so i’d remove the cable from the mech and also remove the mech, reposition the mech to hanger drop link and refit the cable.

legendFree MemberPosted 7 years agoNot much to add but I had a very similar issue when swapping to a bigger cassette on my Five. Was a proper rush job, and the link was parallel to the ground, but couldn’t get my head around what was going on. Need to have another go at it

kayak23Full MemberPosted 7 years agothegreatape – Member

It’s odd. Have you got a picture of your dropout without the mech on?i’d remove the cable from the mech and also remove the mech, reposition the mech to hanger drop link and refit the cable

Mech re-fitted minus the cable, locating tab against the mech hanger stop.

Cable refitted

Clearance is currently ok (26″ wheelset fitted) but still have terrible slipping in smaller cogs(there is a lot of free chain imho from the top jockey to the cassette)

It’s a bit of a mystery really 😐

Goatlink should arrive early next week so I’ll see if it does owt. Otherwise, who knows? May have to somehow alter the hanger or something…

thegreatapeFree MemberPosted 7 years agoThat’s very bizarre. Even looking at other mech hangers yours looks about right in terms of where the tab is. And your mech mount looks fine. It’s just hard to see how it ends up pointing so high??? I’m not sure how the goat link will help if the hanger is somehow wring – I’ve got one, and it does help as its supposed to, but obviously it’s made to work with a hanger that a normal mech works with. If it’s the hanger making that angle all wrong the goat link might be at a bad angle too?

bencooperFree MemberPosted 7 years agoSomething doesn’t look right about that dropout – the derailleur stop should be directly below or very slightly back from the mounting hole, like these:

Yours looks much further back than that.

martinhutchFull MemberPosted 7 years agoHave you got an old mech you could stick on the PP to compare and contrast angles? And vice versa, an old frame you could stick the new mech on to look for differences? That should tell you if you’ve got dropout issues/mech issues or are just going mad.

thegreatapeFree MemberPosted 7 years agoI wonder if the tab on your mech hanger is not quite defined enough?

I’ve been out looking at my bike and I reckon the position of the hanger tab is ok on yours. And even looking at your new photos it’s hard to see why the mount ends up pointing to 10 o’clock not half eight ish. Looking at the hangers Ben posted, perhaps the left hand edge of the tab on yours is not quite cutaway enough and that’s pushing the pin on the mount proud of where it should be. Can you file it away a bit, just at the corner of the tab, to allow the mount to sit properly?

brantFree MemberPosted 7 years agoI know it’s possible on some SRAM mechs to have a tab spun around almost 360deg from where it should be making you think it’s right but it’s not.

Maybe it’s something like that.

I wouldn’t go filing stuff yet.

breninbeenerFull MemberPosted 7 years agoHas this been resolved yet? I have a Shan 27 with both wheelsize dropouts in my attic awaiting build. If anyone wants a photo i will get the parts and try and post them.

ulysseFree MemberPosted 7 years agoSchoolboy error and fairly easy mistake, but is the chain cut too long?

piedidiformaggioFree MemberPosted 7 years agoI’d be taking the cable off and then using my hands to move the mech whilst adjusting the limit screws. It’s surprising how much that arm moves when you make adjustments.

kayak23Full MemberPosted 7 years agobreninbeener – Member

Has this been resolved yet?No 😐

Schoolboy error and fairly easy mistake, but is the chain cut too long?

The chain length doesn’t really affect the position of the mech body as that is limited by the limit tab and the b screw.

A shorter chain would just pull the jockey wheels more horizontal.Have you got an old mech you could stick on the PP to compare and contrast angles? And vice versa, an old frame you could stick the new mech on to look for differences? That should tell you if you’ve got dropout issues/mech issues or are just going mad.

Yes I think so. I’ll try something out tomorrow, though looking at mates bikes, the mech linkage is always more horizontal.

Hopefully production privee will answer my email soon this week. All the PP frames do look to have an uphill linkage though.

piedi di formaggio – Member

I’d be taking the cable off and then using my hands to move the mech whilst adjusting the limit screws. It’s surprising how much that arm moves when you make adjustments.Yeah I’ve done all that. I’ve played with the b-screw until it only just clears the big cog but it’s still got too much free chain on the smalls. The main issue is still when I fit the 650b wheels, where the arm clearance is so small that the chain jams.

Very weird.

Rode it at FOD today (26″wheels) and it mostly behaved until about midway where I had bad indexing issues and a few chain slips.

🙄PJayFree MemberPosted 7 years agoI’m probably being dense, but I can’t see why changing the wheel size should affect the mech; surely it’s in the same position relative to the axle and therefore the cassette? Since the only other thing that’s changed is the dropout I’m inclined to think that there might be a problem there.

NobeerinthefridgeFree MemberPosted 7 years agoHaving very similar issue with sram gx rear mech. Apparently missing a spacer?.

PJayFree MemberPosted 7 years agoI’m a complete numpty when it comes to bike design, but looking at mech. hanger used on my Pipedream Scion, the tab the the mech. stop butts up against starts at the bottom of a curve and itself curves back out, meaning that the mech. stop sits at the back of the curve, roughly 90° to the ground. On the Oka dropout the tab appears to essentially be a triangle jutting out of the hanger with the mech stop resting on a straight side (roughly 45I’m a complete numpty when it comes to bike design, but looking at mech. hanger on my Pipedream, the tab the the mech. stop butts up against starts at the bottom of a curve and itself curves back out, meaning that the stop sits at the back of this, roughly 90° to the ground. On the Oka dropout the tab appears to essentially be a triangle jutting out of the hanger with the mech stop resting on a straight side (at what looks to be about 45°)and looks as if tip the mech. too far forward.

MugbooFull MemberPosted 7 years agoI cut my chain too short (trying to solve rattling chain), this caused my mech to get stuck behind the 36t ring. New chain, added link back in sorted it.

singlespeedstuFull MemberPosted 7 years agoBen and a couple of others have the answer.

I’ve had a similar thing to this on Mrsstu’s Nimble9.

The gear hanger stop is to high/far back and caused the arm of the mech to catch the cassette when i fitted a 42 expander cog.

The simple solution was the grind the stopper tag on the mech to allow it to sit in a further forward position.

See the tab on the mech that’s stopping the mech from rotating forwards in this pic.

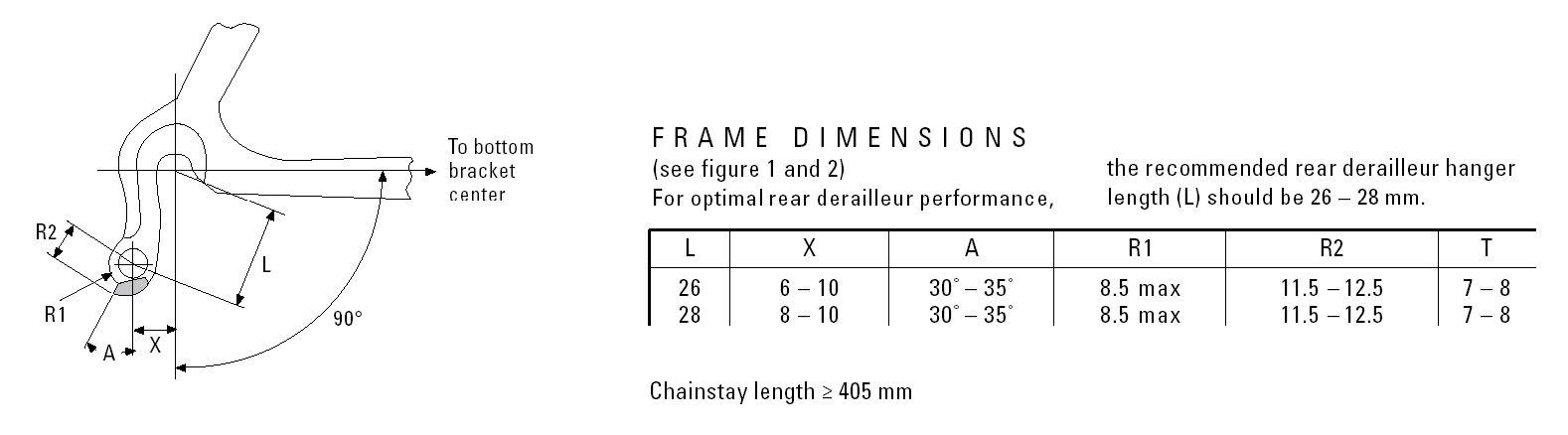

You need to grind that back to allow more rotation on the mech.mlindaretsFull MemberPosted 7 years agoAs someone who’s spent a bunch of time with stock and tweaked derailleurs (and the guy who designed the GoatLink), I’m going to say that (as others have suggested) the hanger looks way off. Here’s Shimano’s specification:

The b-tab looks to be quite a good 10-15 degrees further clockwise from where it should be, which will muck with the derailleur position, reducing chain wrap and impacting shifting. Shimano DM rear derailleurs (with a DM link) aren’t really adjustable there, so any weirdness is amplified. Have Production Privee been responsive to any messages?kayak23Full MemberPosted 7 years agoHave Production Privee been responsive to any messages?

Not yet, but it is the weekend so I’ll wait a bit.

See the tab on the mech that’s stopping the mech from rotating forwards in this pic.

You need to grind that back to allow more rotation on the mech.That mech seems to have more meat on the mech tab. My SLX has much less I think so not so much room for filing. Might have to be what I try though.

PJay – Member

I’m probably being dense, but I can’t see why changing the wheel size should affect the mech; surely it’s in the same position relative to the axle and therefore the cassette? Since the only other thing that’s changed is the dropout I’m inclined to think that there might be a problem there.Not being dense at all. It really doesn’t make sense.

I’ve compared both dropouts and they look like the distance from the axle centre to the mech mount centre is the same so yes, makes no sense.singlespeedstuFull MemberPosted 7 years agoThat mech seems to have more meat on the mech tab. My SLX has much less I think so not so much room for filing

It was a Zee mech that i filed down so it had an equally small tab to the SLX.

I’ll try and remember to take some pics of it if you want. It’s just sat on the bench as there’s now an 11 speed XT on there which works with any addaption.molgripsFree MemberPosted 7 years agoBtw, if it hasn’t been said yet, slipping gears when you change your chain is caused by the cassette being also too worn.

kayak23Full MemberPosted 7 years agoBtw, if it hasn’t been said yet, slipping gears when you change your chain is caused by the cassette being also too worn.

Brand new cassette same time as chain. Sunrace 11-42

kayak23Full MemberPosted 7 years agomlindarets – Member

As someone who’s spent a bunch of time with stock and tweaked derailleurs (and the guy who designed the GoatLink), I’m going to say that (as others have suggested) the hanger looks way off. Here’s Shimano’s specification:

Very useful to have your input Mr Goatlink, thanks.

So do you think the Goatlink will improve matters or not make much difference?

Ultimately I may have to see if I can get different dropouts machined maybe.The b-tab looks to be quite a good 10-15 degrees further clockwise from where it should be, which will muck with the derailleur position, reducing chain wrap and impacting shifting.

I think this is clearly the root cause of the issue. Funny though how with the bigger wheels (and appropriate dropouts) that the cable tension arm is so much closer. Perhaps the dropout is laterally different too? 😐

Such a shame as the Oka is just amazing apart from this little issue.

kayak23Full MemberPosted 7 years agoUpdate. No word from Production Privee as yet but I got my Goatlink already and it’s improved things a lot.

All shots with 27.5″ wheelset and dropouts fitted.

A shot of the mech with the original drop link.

The Goatlink fitted alone

The Goatlink and mech fitted. Looking way more horizontal

View from above with normal droplink on

View from above with Goatlink fitted and B-screw still wound in. Seems like more clearance

Goatlink fitted and now with B-screw wound out a lot as it needn’t be in so much to clear the 42t ring. Seems like a little more clearance.

Basically it now works in a slow ride around the road outside me house however, changing down the cogs the response is very slow. I had a hell of a lot of trouble getting the cable to take the mech onto the big ring despite the limit screw easily allowing it.

Once I got it to do it by tensioning the cable, it then seems to take about a week from shifter click to movement down the cog…. (brand new cable and outer)

It’s sort of working anyway which is better than before but I’ll still need to see if it slips under power and get the indexing better.thegreatapeFree MemberPosted 7 years agoI think your original theory is correct – the dropout ain’t right. But glad it’s working a bit better.

mlindaretsFull MemberPosted 7 years agoSorry- Labo(u)r Day holiday over here so was out on the trail most of the day 😀

I’m glad that the GoatLink has helped! The skipping you felt at the bottom of the cassette was almost certainly due to insufficient engagement- the cause being the funky hanger and exacerbated by the additional B-tension required by the oversized cassette.

While the GoatLink will help bring things back towards stock, you’re still unwrapped a fair bit relative to what one would expect with a conforming hanger and 11-36t cassette. (If anyone wants to get into the weeds: stock is ~140 degrees engagement in the 11t and as photographed it looks like you’re closer to 110 degrees (chain entering around 8:15, leaving at 12:00).) If you spend most of your time in the top half of the range things will likely be fine. On the other hand, if you spend a lot of time in higher gears (commuting, riding to/from trails, or just being a badass), you’ll probably see faster drivetrain wear (cassette wear and chain stretching)- something you’ll want to keep an eye on and probably be proactive about replacing chains.

Also, as the top jockey wheel moves away from the cogs, shifting won’t be as crisp as it could/should be in high gears- but that’s less noticeable than you’d feel with fresh cables and housing.

Ultimately, it looks to be a solid improvement- but I hope that the manufacturer comes through for you with a conforming hanger/dropout. There’s enough going on there that a custom dropout won’t be inexpensive- the machinist be starting from a fairly thick plate, machining from both sides, and using some uncommon (in the US) taps. An alternative would be to file a few mm off of the GoatLink where it contacts the B-stop. The GoatLink is pretty stout- just try to stay square to the mounting face and keep the file aimed at the center of the mounting bolt. Good luck!

Marc

The topic ‘Drivetrain clearance issues doing me nut. Anyone use a Goatlink?’ is closed to new replies.