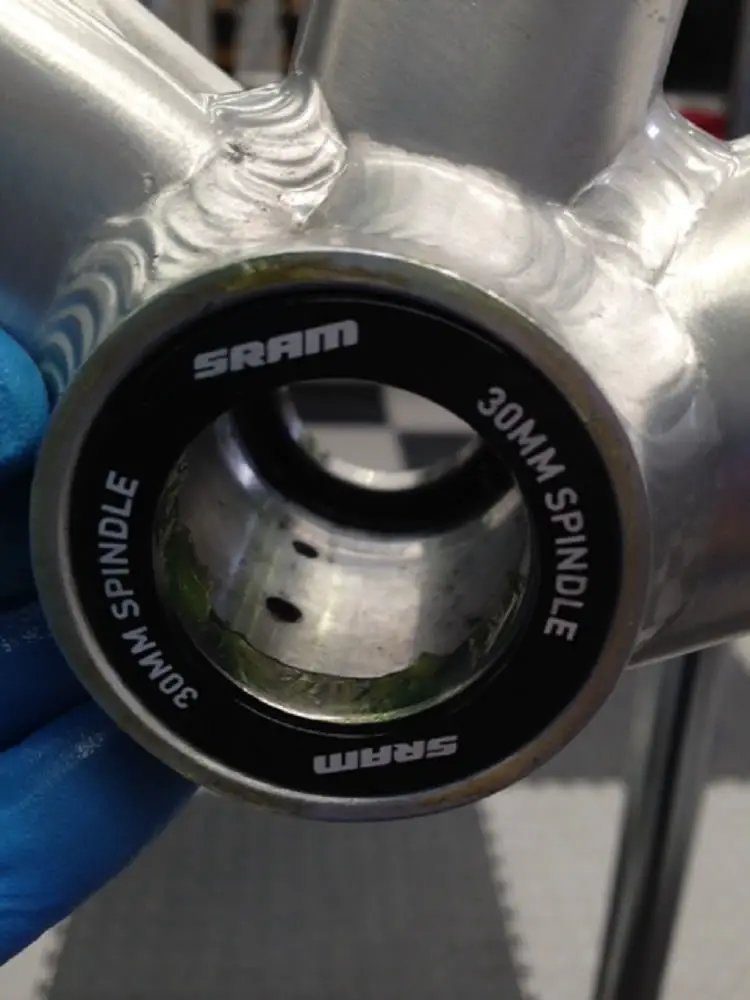

BB30 BEARING REPLACEMENT

DIFFICULTY RATING: 3 OUT OF 5

WORDS AND PHOTOS BY JULIAN THRASHER

The much-maligned BB30 bottom bracket standard is subject to many woes and potential creaks, and the need to frequently replace the bearings is something you will no doubt have already heard.

Water has a tendency to find its way into a ’cross bike frame and can pool in the bottom bracket area, sloshing against the somewhat delicate seals of the bearings. Thus, you need to pay special attention to your bottom bracket, looking out for signs of wear. You’ll know it’ll need to be replaced when:

Play is felt through the crank arms when they are rocked side to side

You hear creaking or cracking noises coming from the bottom bracket area

The cranks seize in position after the bike hasn’t been ridden for a couple of days

Tools and Materials Needed:

- 10mm hex key

- Drift to remove the bearings

- Soft blow mallet

- Internal circlip pliers

- Bearing press and adapters for BB30 bearings

- Torque wrench with hex key fitting

- Degreaser

- Copper grease

- Teflon grease

- New BB30 bearings and seals

Removal and Replacement of the Bottom Bracket

Make sure the bike is clean before replacing the BB30 bearings, as muck stuck in the bolt head of the crank increases the chance of rounding the head of the crank bolt.

The cranks shown here use a ‘one key release’ system, and are removed by loosening the 10mm hex bolt in the centre of the non-drive crank arm. Keep undoing the bolt and the crank will slide off of the spindle.

Clean the splined spindle.

Use a soft blow mallet to tap the drive side crank and chainrings away from the bottom bracket. (Make a note as to the direction and order of any removed seals so that you can put the new ones on in the correct order.) The BB30 bearings butt up against circlips inside the frame. Be careful when drifting the bearings out of the frame so that you don’t hit and bend the circlips!

Remove the circlips from the frame and scrupulously clean the internal surface of the bottom bracket shell. The shell needs to be clean as any dirt that is squeezed between the bearing and the shell has the potential to cause creaks.

Install the new circlips, and apply copper grease to the bottom bracket shell.

Press the new bearings into the frame, making sure not to press directly on the inner edge of the bearing. It’s important that the bearings go in straight – so take your time with this bit. Stop when you feel the bearing make contact with the circlips.

Install any seals onto the drive side crank arm.

Apply a small amount of Teflon grease to the inside edge of the bearings.

Install the drive side crank and slide on any remaining seals.

Grease the splines and install the non-drive crank arm. The correct tightness is important so use a torque wrench when tightening the crank bolt.

If you’ve been careful to press the bearings in correctly and worked cleanly, then you should find that the BB30 bearings are smooth and silent under power. Keep them clean and they’ll stay happy!