- This topic has 47 replies, 28 voices, and was last updated 7 years ago by Northwind.

-

Ti V 853

-

twistyFull MemberPosted 7 years ago

Tosh.

I thought I was being reasonably balanced and realistic with my advice.

But this detailed and well reasoned response has shown me that clearly I was wrong, it is wrong to even contemplate Ti. No need to think about it, just buy an 853 frame because it is the magic metal, it is stronger, it is bombproof.But make sure it is never clamped into a workstand because the tubes will crush…

metalheartFree MemberPosted 7 years agoI have a Mk I Soul and loved it so much got a Soda as, hey, it’s an even fancier a Soul, right? And I’d wanted a Ti frame for, oh, knocking on 10 years….

I didn’t get it, there was definitely more ‘spring’ and the 31.6mm seat tube (over the 27.2mm steel one) made the transmission way more direct. But I guess I probably didn’t ride it often (or hard) enough.

In the end I did a 5 hour route with a mate on a newly built up Solaris and where we were swapping about (both my bikes) and despite the 29er only being my 4th ride on it to me felt so much better. I sold on the Soda not long after that.

I’m currently seriously considering a 650B+ bike and options are a custom Ti Pact or new gen Sherpa. Despite the benefits of being able to get a slightly longer, slightly slacker version of my Solaris with boost rear and choice of cable routing I’ve a Sherpa on reserve. 50% cost and the nagging doubt of the Soda experience being the deciding factors.

Re. non 853 rear ends on ‘853’ frames somewhere on the Cotic website Cy explains his use of same. Iirc there is no difference in weight or stiffness so it would only make a frame more expensive with no real world advantage.

bucksterFree MemberPosted 7 years agoI think that in making steel lighter, strength has to come from the tube profile. This in turn stiffens the tubes and makes the ride characteristics different. For the sake of a pound, which makes no real world difference, is it even worth bothering?

cubicboyFree MemberPosted 7 years agoJust for balance, I bought Metalheart’s Soda. It was springy, taught and exciting to ride. I sold it because it had 26″ wheels. I regret that.

Unlike a painted bike, titanium doesn’t pick up scratches or small dings; my 10-year-old titanium road frame still looks brand new.PeterPoddyFree MemberPosted 7 years agoBut a quality well designed Ti frame will be stronger and more bombproof than a similar 853 steel one, not weaker.

Really?

Surely the same careful design using a material of around double the strength will be stronger…..

Honestly My heart weeps None of my MTB’S ever broke I know another guy who did the barrier bike roofrack thing , not a sausage

The roof rack thing is pure good luck. No more no less.

I’m going on what I’ve personally experienced and seen in the bike trade. Considering how many Ti frames there are out there (not many) the failure rate is too high, trust me on that! 🙂

Give the choice of pretty much anything I’ve got 2 alloy and 3 steel bikes. 🙂jamesoFull MemberPosted 7 years agoBut a quality well designed Ti frame will be stronger and more bombproof than a similar 853 steel one, not weaker.

Really?

[/quote]

Agreed in the main PP but also depends what ‘similar’ means, or ‘strong’. Dent resistance, resistance to fatigue cracks at the weld, pre and post weld strength, etc.

Also frames are often made to a safe design then taken to a stiffness level – if you stopped at ‘safe’ at the lightest weight with Ti or steel you could have what some might call a whippy mess of a ride. So you go for adequate stiffness, a good stiffness to weight ratio. ie give me a stiff-enough steel frame at close to 5lbs over a floppy frame at 4lbs, or 3 1/2lbs vs 2 3/4 for Ti road frames ime, etc.

Comparing ti and 853 is a bit futile and there’s so many half-truths about it all. Basically, buy ti if you want ti, it can make a great riding frame and it’ll be a bit lighter. If I wanted durability I could trust over 20 years of regular use and touring for ex I’d go for 853 with a bit extra on the tube spec to get that durability.

Added to that you might be able to get a bike made closer to what you’re after in steel simply as there’s more builders working with it. That counts for more than the material for a good custom bike, imo. Could get 2 frames made for the price of a ti frame too, could be useful as ime the first frame to a design isn’t often 100% right anyway.

twistyFull MemberPosted 7 years agoYo PetterPoddy, and 100% agree and guy who called my comments Tosh.

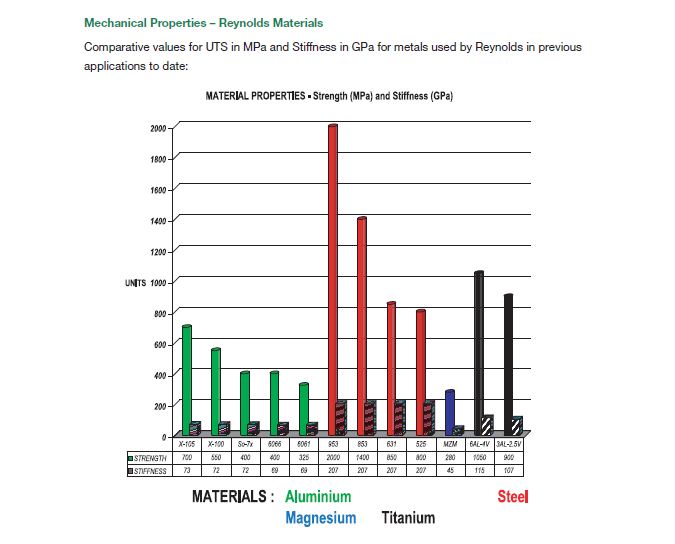

I’m going to take a step back at this point and admit I threw my toys out of the pram a bit, why – because that whilst there is some good thoughts in this thread I think there are also some half truths and this winds me up because I am a technical pendant.The graph

Proves that if you compare strands of material with a 1.sq.mm cross section the 853 one will pull up a mighty 1400N and the Ti 3AL-2.5V a puny 900N.

This isn’t particularly relevant because we are not talking about structural suspenders, bicycle frames are not tubes pulled in tension. Okay there is a ‘stiffness’ in there which is a bit more relevant but we don’t even know what that really is, Youngs modulus?, shear stiffness?, torsional stiffness?, what half-assed engineer didn’t label that figure correctly grr, grumble.

Titanium of course has a much lower density than iron, and the graph would be a bit more relevant if it was normalised to account for density, but then again it was made by Reynolds and they wanted their materials to look as impressive as possible.The Bombproof thing

Considering how many Ti frames there are out there (not many) the failure rate is too high, trust me on that!

Give the choice of pretty much anything I’ve got 2 alloy and 3 steel bikes.Well I personally snapped an Aluminium alloy frame in ~3 years, bent an Aluminium frame in 2 weeks, and cracked a steel frame in about 2 years + 2 years of original careful owner.

If I thought about it superficially then I could conclude that Aluminium and steel make rubbish frames, and the Titanium is the magic metal because my Ti frame has lasted for 16+years plus a few years use from original owner. However, the world far more complicated than this and there are a variety of reasons for the failures and success of the frames beyond picking frames from the periodic table.

You’ve witnessed failed Ti frames, but why did they fail – what are the underlying reasons?

Many moons ago I tried to organise a group buy of imported Titanium frames.

I put a lot of time into it, talking to a few different factories in China, looking at the geometries and tube profiles, working out which manufactures they distributed too. I had enough backers to make it work but in the end I stalled and pulled out of going through with it. Why? Because I felt too much personal responsibility over the quality of the frames when they were delivered. My research found, amongst other things, that doing the welding just right is critical to the integrity of the frame and I wasn’t able or even capable of overseeing the QA of the manufacture.

After this time I did see quite a few of the online shops were selling cheap imported Ti frames, I wonder if these are the type of frames that you have seen failing? There was also a time when people tended to make Ti frames with small tube profiles to accentuate the Ti whippy feel and those might also be prone to fail.So you’ve read all that technical answer to technical stuff, here is the point

The reason I referred to Ti as a bit lighter and bombproof as in my view as an experienced MTBiker and engineer compare a 4.5lbs 853 frame to a similar 4lbs Ti frame, or even a 4lbs 853 frame to a 3.5lbs Ti frame – the Ti frame will have thicker tubes and generally be more resilient, mash the chainstay on a rock it is less likely to dent, land a large drop off angle you are less likely to twist the rear triangle, crash it into a tree the headtube is more resistant to folding into the frame, it is far less likely to dink/crease/fold if you mash something (e.g. rock / brake lever/ fellow competitors frame) into one of the tubes or a large stone flicks up and hits the downtube, it doesnt even have paint to chip, etc.Yes I didn’t qualify in my original post that you do need to make sure that Ti is welded together properly, and that is is a reasonable design. However, I wasn’t getting all misty eyed about the benefits of Ti either.

NorthwindFull MemberPosted 7 years agoLots of ti frames break and it’s because of 3 things

1) It’s not the easiest material to work with

2) Some of the big names aren’t actually very good at it (and people go “Well if a Lynskey breaks then they must all be fragile, because Lynskey is teh best”. It’s like buying an Intense and saying “aluminium sucks because the frames are always welded squint”

But most important is 3) Most people who buy a ti frame want it to be as light as possible, and like the idea of a flexible frame, and that obviously affects strength. If you buy a super-light frame of any description then complain that it’s not as strong as a much heavier frame, you deserve it if it breaks.

The topic ‘Ti V 853’ is closed to new replies.