- This topic has 167 replies, 50 voices, and was last updated 7 years ago by monkeyboyjc.

-

New bike day – just need to build it….

-

monkeyboyjcFull MemberPosted 8 years ago

The new frame turned up in its box this morning – just need to put it together… 🙂

chakapingFree MemberPosted 8 years ago

chakapingFree MemberPosted 8 years agoNice, can you play a tune on it as well?

[video]https://www.youtube.com/watch?v=Z1lTXhXTasA[/video]

mrsfryFree MemberPosted 8 years agoDoes it smell like bamboo? Do you need to dip it to make it strong?

How long will it take to build? Are you finished yet?More pics please 🙂

bearnecessitiesFull MemberPosted 8 years ago🙂

Plant it in the garden and another will probably appear through your lawn.

monkeyboyjcFull MemberPosted 8 years ago@ mrsfry

Yes it smells like bamboo

No you don’t need to dip it, although some people do a resin coat over the whole thing at the end.

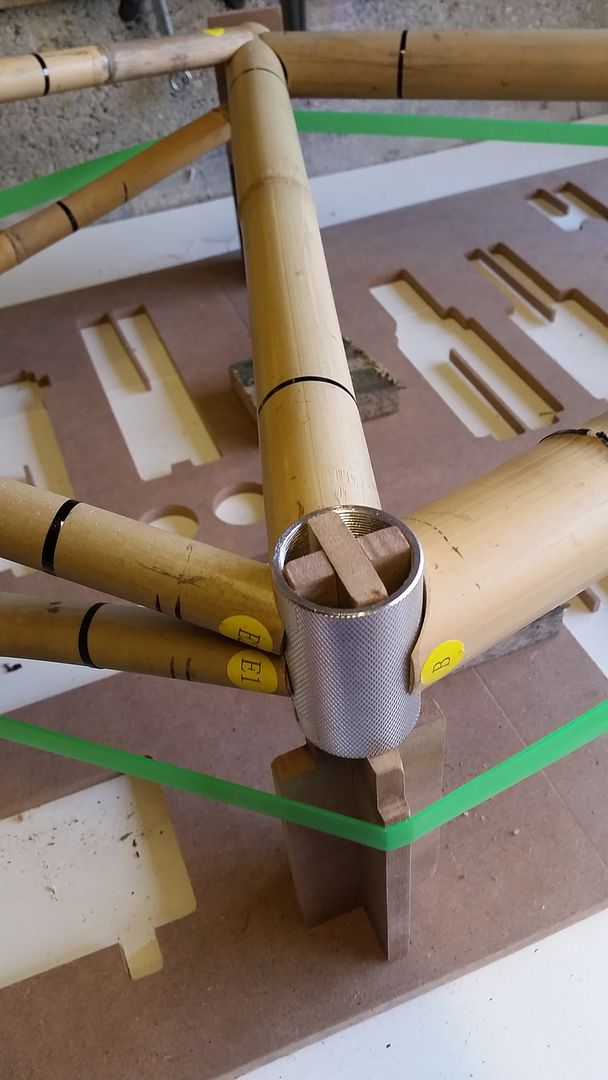

It should take a couple days to get it stucktogether and wrapped – but + another 30 hours or so of sanding for a decent finish.monkeyboyjcFull MemberPosted 8 years agoGot the jig (it comes with one) built and it mocked up this afternoon….

The bb and headtube (1&1/8) come pre knurled which you don’t get with some kits

z1ppyFull MemberPosted 8 years ago

z1ppyFull MemberPosted 8 years agoExcellent, keep up with the build pictures.

What geo, is it a std kit or can it be customised?monkeyboyjcFull MemberPosted 8 years agoIt’s a standard kit from bamboobee.net – there’s no detail on geometry on the Web site and tbh you’re never going to get 100% accuracy as every joint has around 1-2mm of play. It’s a ‘standard’ medium road bike kit so it was £180 ish all in wit postage.

Postage was quick – 5days via dhl from Hong Kong.

Cost was £160 but I also bought 2 sets (8 bolts) of bottle cage kits which i’ll use as bolt on cable guides.

I’m going to try to tweek the cable routing so that it’s integrated through the lugs – kinda semi internal. I’m using 8mm ali tubes for this.

Bamboobee also have a full ‘how too’ on youtube if anyone’s interested.

monkeyboyjcFull MemberPosted 8 years agoSpent the last hour rasping 4 of the joints – you need to roughened the bamboo around the joint area so that the resin and hemp gets a better key.

Only 10 more joints to go – think I may get the power tools out…Also thought I’d post a pic of the double tube construction bamboobee have used for the main triangle – the main tube us reamed out and a smaller one bonded in. Not sure if it’s entirely necessary and will make a heavier frame but it’s nice anyway.

bikebouyFree MemberPosted 8 years ago

bikebouyFree MemberPosted 8 years agoWell, this thread is excitement enducing.

I like ( hits the like button )

Be great if you can find time for more pics, this could turn out epic.

😀

monkeyboyjcFull MemberPosted 8 years agoI’ll try to do pics as I go but I’m afraid it’ll be a bit hit and miss. I’m aiming to get it tacked up in the jig by the end of Monday – then glued and wrapped over the next couple weeks.

monkeyboyjcFull MemberPosted 8 years ago

Just finished tacking up the frame. I’ve used gorilla glue as it expands into the joints and will help fill some of the tighter gaps that the hemp / epoxy mix won’t reach. Others have used balsa joints or fibreglass to further this but this kit didn’t come with that so i’m not going to bother.

Getting it all aligned was a bit of a pain – lost of measuring and re measuring – I’m still not sure if the drive side stays are correctly aligned – if I were to do it again I’d make my own upright jig.

Also had to use most of the zip ties in the kit to keep it tight – IT also comes with wire sections for added strength but i’ll replace so of these with Ali tubes for my cable routing after its tacked up.

^^ this is my biggest concern – you can see the non drive side dropouts are nice and tight in the pre cut slots, but they are no where near on the drive side. I’ve measured it three times and the drop outs are the same distance from the BB. I may have to remove it from the jig to tripple check the alignment which will be a real pain (and may kill the jig in the process (I hope gorilla glue will be strong enough).MTB-IdleFree MemberPosted 8 years agolooks good altho slightly terrifying.

A bloke I chat to on my daily cycle commute on CS7 rides one of those. Ridden it for years.

scaredypantsFull MemberPosted 8 years agobamboobee.net

Ah, now I see how you ended up finding this

cookeaaFull MemberPosted 8 years agoJust spotted this thread and I is all excitement now…

Hadn’t come across bamboobee before only bamboo bicycle club who’s kits seems a little pricey, seem to want to coax you on a course in London and rent you a jig…

I really like the flat pack jig idea…

Did you have many extra costs / problems importing the kit from the states?

Edit just read the post abovemonkeyboyjcFull MemberPosted 8 years agoNo import taxes – came labeled up as ‘sample bicycle components’…..

Just about to start the wrap…. not sure if it comes with enough hemp for a good ‘all over’ finish – the instructions show part of the headtube exposed and several of the customer pics show this on there bikes. Luckily I have a big ball of hemp string which I can over wrap with if needed.

bikebouyFree MemberPosted 8 years agoLooking good, I see your point on the joints.. But hey, it’s not like you’ll be riding it tomorrow is it? Is it?

Maybe take it out at night first 😯

Thanks for the photos, I know we’re all “more, more” and it’s a problematic grabbing the phone with glue on yer hands, but we are excited for you 😀

monkeyboyjcFull MemberPosted 8 years agoHere’s what it looked like an hour ago…

You can see how I aim to run the cables internallyto the lugs with 8mm ali tubes which should be easily enough to file down with the joints.monkeyboyjcFull MemberPosted 8 years agoAnd here it is now:

I have to say it was a tricky disgusting process – 1kg of epoxy and really long lengths of string = one big sticky mess. I fully expect to find the jig stuck to work bench in the morning.

I’ve also realised that routing the rear break down the down tube won’t give the best route along the chain stay – should have gone under the top tube with them both. I’m aiming to go 1×10 so no front mech routing.

Another issue with a flat jig is that I couldn’t see the none drive side so there will be LOTS of tidying up to do on that side – you can see how lopsided the BB area is…Just 12-24hrs for it to cure before jig removal (big mallet and swearing to be involved)…

cookeaaFull MemberPosted 8 years agoRe the DS dropout could you maybe pack out the slot and inside of the tube with some epoxy? Maybe with some GF filler?

Would you be at all tempted to reinforce the joints with the blackstuff before wrapping the hemp over? Or is that a No-no…

Ooooh another thought, might not be your bag, but what about directly bonding a guard and/or rack while it’s still on the jig?

monkeyboyjcFull MemberPosted 8 years agoI filled the extra long slots with extra gorrila glue and it should be ok.

Not sure on the build yet – but I doubt I’d ever use a rack and it won’t see the rain (I hope) so shouldn’t need guards – the same company makes bamboo do-it-yourself guards as well so it’s always an option in the future.

Need to buy loads of mini grinding and sanding bits for the dremel – it can take 60+ hours to finish the lugs nicely and with that second of wayward hemp around the BB I may need to find a bench mounted belt sander.

I’ve kept most of the bamboo dust from filing the joints to make filler incase there are any bits of exposed bb/headtube etc.mtbtomoFree MemberPosted 8 years agoI’ve seent the company in the UK that sells the kits but that looks pretty good too. Does it come with dye to colour the joints?

fd3chrisFree MemberPosted 8 years agoThat close up of the head tube looks like a sand people off of star wars.

monkeyboyjcFull MemberPosted 8 years agoNo dye – u wanted to see what the cotton / hemp mix looks like first.u can always mix up a coloured epoxy layer to go over the top. But TBH what’s the point In a hemp joint if you then colour it after.

I’ve seen plenty of sprayed up joints as well.monkeyboyjcFull MemberPosted 8 years agoThat close up of the head tube looks like a sand people off of star wars.

Hopefully it won’t once it’s sanded down.

mikeysFull MemberPosted 8 years agoWow – good effort.

I’ve been thinking about getting a kit like this from the London bamboo company and building up a 29er to go with some singular swift forks as a commuter. So really interested to hear how it finishes up and especially how it rides.

Good luck and keep up the updates!cookeaaFull MemberPosted 8 years agoBeen pouring over the bamboobee site this afternoon, noticed this:

dropouts (127 mm apart on jig)

Is yours spaced 127mm? I noticed it has disc tabs will it stretch comfortably to take a 135mm hub, or could the jig be re-spaced?

nikkFree MemberPosted 8 years agojoints

resin

big ball of hempUuh, you sure it is a bike frame you are making?

😀

mrsfryFree MemberPosted 8 years agoWOW! You have skills

Loving the pics and thank you for the reply 🙂

monkeyboyjcFull MemberPosted 8 years agoIs yours spaced 127mm? I noticed it has disc tabs will it stretch comfortably to take a 135mm hub, or could the jig be re-spaced?

Yes they are spaced at 120mm. A 130mm disc hub will fir and there are still some about, I’m aiming to get some novatech hubs for the bike.

cookeaaFull MemberPosted 8 years agoHmmm, I would be tempted to modify the jig to make 135mm fit…

I am very keen on getting one of these kits, but I want to see how your exploits turn out…

What are you doing to finish the joints? looking about packing over with hemp wool, sanding and polishing them up smooth looks like the most popular choice…

The topic ‘New bike day – just need to build it….’ is closed to new replies.