Subscribe now and choose from over 30 free gifts worth up to £49 - Plus get £25 to spend in our shop

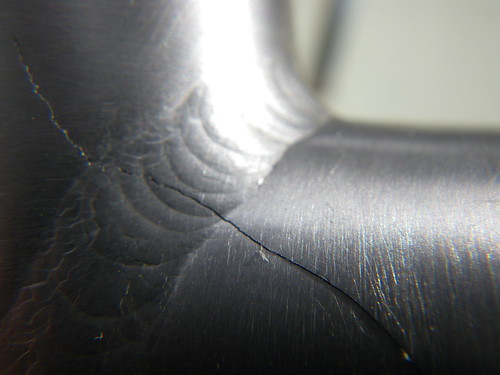

So without going into details my Titanium frame has cracked around the seat tube/top tube weld.

The frame is just within it's warranty of 4 years (runs out early November) and the warranty is only a half price replacement. The new versions of the frame are £500 more than what I paid new.

I haven't contacted the manufacture yet as my bike is fully insured against breakages etc so though I would contact them first.

They can't inspect the bike until 5 November at the earliest 🙄

However they have said that if the frame can be repaired they will do that. Now I am not very happy about this, and maybe jumping the gun but I pay a lot of money to insure my bikes and don't want to be riding a bike with a nasty patch up weld, and also as a 14 stone lump have lost confidence in the frame.

Has anyone had any experience of dealing with insurance companies trying to fob them off with a repair? What happened?

I have attached a pic. Can it be repaired?

MM

Just leave it to the insurance warranty people to sort out. If your not happy with what they do to it then take the matter further - just don't jump the gun - good things come to those that wait.

So how did it happen? I ask because the first thing that the manufacturer is going to think/say is, 'can we see your seat post please' because that looks for all the world like you've been running too much seat post.

Not sure though I understand what it is you're asking, but what I don't get is why you would have an insurance policy for breakages on top of a warranty? I can sort of understand why an insurance policies first response would be to try to fix it and why you wouldn't be happy with that, but then I think that's a learning curve on insurane policies. I've seen other Ti frames that have been fixed and the outcomes are usually pretty good, almost to the point where the frame wears the very slight scar with pride.

If the insurance co can get a reputable person to say a repair is safe then why not? I bet they won't tho. I guess its the default position of " we will have to see if it can be repaired" until seen by an engineer rather than anything else

the warranty is only a half price replacement.

Ouch.

Are the company trying to run the clock out ie wait until early november then say "sorry just outside 4 year warranty, so we'll repair it for you blah de blah....."?

If an earlier inspection could assist replacement I'd get the bike to them sooner, cost of travel would be met by frame replacment etc.

Agree with GT that company will want to see seatpost, too short a post insertion past that seat tube top tube junction might have contributed to cracking.

There is 14cm of Thomson post in the frame. Warranty says 10cm minimum.

I'm 6'1" on a large frame.

Just come back from a weeks riding in Spain and noticed it when cleaning the frame on returning.

My insurance covers theft and breakages as long as not used for 'racing'. I have not mentioned to them that it is only just in warranty. I haven't contacted the manufacture yet, but having snapped a frame of theirs already (steel) I only got a discount off a new frame so don't hold out much hope for a good deal.

MM

contact manufacturer now. inform them of the situation.

I have seen similar cracks repaired. and recrack. to be repaired with a sleeve.

[i] but I pay a lot of money to insure my bikes [/i]

Try M&S insurance, mine are included in the house contents and cost next-to-nothing (contents at £120 all-in).

As to the actual repair - I'd just contact the manufacture direct, in the first instance. For example; I recently ****ted my Ti frame, and On-One/Lynskey repaired it for £100 all-in, including shipment etc.

Incidently how much seatpost was there 'inside'?

Edit - sorry x-post - 140mm seems a decent amount...

Psychle has had exaclty this repair done IIRC, may be worth speaking to him.

Some insurers won't even inspect if you get something from your tame lbs to say it is not repairable. Contact the insurance. Company and ask what they need!

4 years? i though ti frames were 'a bike for life'?

be interested to see what your insurers say. maybe if you tell them of the crash replacement price they will pay that instead of RRP?

I thought the Sodas had a lifetime warranty?

The new ones do. Seems my 'old skool' model doesn't according to the reciept/warranty.

The frame is just within it's warranty of 4 years (runs out early November) and the warranty is only a half price replacement. The new versions of the frame are £500 more than what I paid new.

erm, what brand is this? Pretty crappy "warranty", especially for a Ti frame.

edit - just saw your post above. That warranty takes the p*ss imho.

That warranty takes the p*ss imho.

And presumably was publicised before the frame was sold?

Should have bought a carbon frame. 😉

I've snapped Steel, now Ti....and I have a carbon road frame. Oh oh!

Be careful and good luck with the claim. 😀

Funny how Cotic's Ti frame went up by £500 while On One's came down by almost as much!

IMO quite a disappointing warranty! After 3 years my Van Nic road frame cracked at BB weld, leaving big hole, sent back to dealer and no questions asked a replacement arrived within 4 weeks, quite quick given it was over Xmas / New Year period. Was disappointed to have frame break but the lifetime warranty was duly honoured without question. I think you should push mfr harder to get this resolved asap by a full replacement no qs asked

I haven't contacted the manufacture yet

Given I suspect the manufacturer and the company you bought the frame from are one and the same thing, you need to talk to them first (they should always be the first port of call in a warranty incident), before doing anything about insurance. If the frame is what I think it is, then the guys in question are pretty reasonable. Go talk to them.

i though ti frames were 'a bike for life'?

Marketing bulshit alloong with

Lightweight Carbon Composite - theres barely if any weight loss over the aluminium versions, but people want to see a return for their money when buying an expensive model.

Steel is Real - no its just steel, its not iSteel, its just as real as aluminium.

Aircraft Grade Aluminium - well at least its more truthfull than On-Ones being made from Doncaster gas pipe. The foam in easyjet's seats is probably 'aircraft grade', I wouldn't build a frame out of it though?

So what make/model is the frame?

Doubtful that can be repaired satisfactorily - as the crack that starts at the TT/ST junction weld extends vertically down the side of the TT away from the weld.

I'd be VERY wary of riding a frame like that after a repair - it looks like an accident waiting to happen.

Thought that looked like a Cotic... Good luck with it

"I've snapped Steel, now Ti....and I have a carbon road frame. Oh oh! "

Yes, stuff breaks.

Bad design is bad design regardless of the materials used.

Just having a quick look at the picture, I would be curious to know what the inside of the top tube looks like. There may have been insufficient purge / shield gas (argon) in the toptube during welding to prevent the tube absorbing oxygen or nitrogen from the air. In which case there will be visible discolouration of the inside surface of the tube, meaning that it is impossible to do an effective repair.

Once titanium (a weld or parent-metal) absorbs too much oxygen or nitrogen (although commercially pure titanium can rely on tiny amounts of oxygen for some improvement in strength) then it is likely to crack.

http://www.singletrackworld.com/forum/topic/welding-titanium-where

Aircraft Grade Aluminium - well at least its more truthfull than On-Ones being made from Doncaster gas pipe. The foam in easyjet's seats is probably 'aircraft grade', I wouldn't build a frame out of it though?

Yes, but aircraft grade Aluminium is manufactured to very tight quality standards because they need to accurately be able to predict fatigue damage etc. for service intervals. Not quite the same as the foam in easyjets seats!

Take it up with the brand.

That's the down side with an expensive ti frame, repairability especailly after warranty.

Best of luck

poppa, are you suggesting that a grade of aluminium, say 7075-T6, is different if its made for an aerospace as opposed to any other application? It either is that grade or it isnt.

Aerospace is the major customer for aluminium alloys so all manufacturers supply that industry, so all their alloys are "aerospace grade".

Alcoa had more difficulty making aluminium components for the Audi A8 than they do for Boeing.

The early TI Cotics I believe were made in Taiwan, the latter models were Lynskey made.

In a repair scenario the TT would need to be replaced, a blob over the top of the crack would be a bodge job and I definitely wouldnt feel comfortable riding it with my 12 stone let alone your 14. Getting the TT replaced will probably cost Cotic more than it would be just to hook you up with a new frame.

Good luck.

For me working in an industry that uses fabricated ti and alloy regularly that is not a good repairable option. If the crack was around the weld and only on the weld, then it would be less serious. In this case it looks like the tube itself has failed. The crack has then run around the tube . Butt welding tubes that are under tension is not ideal. Not a good repair.

If it was a last gasp attempt to fix or bin perhaps you could re-weld then add a a gusset between seat tube / top tube to support the seat tube and help spread the load between the tube junction.

Nicolai style gussets FTW

[url= http://farm5.static.flickr.com/4145/5089707982_2350309209_z.jp g" target="_blank">

Not an unfamiliar tale.

"Bike For Life" my gullible arse.

johnners is that seat tube / seat stay? Looks a really strange route for the crack. What did the manufacturer say?

"poppa, are you suggesting that a grade of aluminium, say 7075-T6, is different if its made for an aerospace as opposed to any other application? It either is that grade or it isnt."

Is 7075 a grade?

http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA7075T6

"Agreement may be indicated, for example, by reference to a standard, by letter, by order note, or other means which allow the Zr + Ti limit.

Aluminum content reported is calculated as remainder.

Composition information provided by the Aluminum Association and [b]is not for design[/b]."

An aerospace grade material will have an agreed specification for where in the original melt / ingot it will come from (the middle, the rest will be sold to bike companies) plus the NDT protocol to be used on the NDT of the billet (test for occlusions and inclussions etc) and whateverelse they buyer specifies eg grain refinement etc. The top of an ingot usually has some contamination and defects in it (flaws, cracks which develop during the cooling of the ingot.

So even if it comes out of the same melt (mix) it can be the rejects (dross) from the aluminium manufacturing process.

Looks a lot like the sort of thing that happens with very thin (too thin a) wall thickness. The reason for butted tubes is to have enough thickness of metal to avoid this type of failure.

Blimey!

I've never been attracted to ti - thankfully. Right bummer for those that are going through the warranty process, hope it all works out ok for those concerned.

I've gone for custom steel, specced some beefed up head and down tubes. I know steel cracks too, but it's much easier to get a tube fillet brazed in, and not that pricey either. Hopefully I won't need the latter - again! 🙂

johnners is that seat tube / seat stay?

Seat tube/Top tube.

didn`t manage to post pic......to join gallery of Ti cracked welds etc!

Looks a lot like the sort of thing that happens with very thin (too thin a) wall thickness. The reason for butted tubes is to have enough thickness of metal to avoid this type of failure.

All the examples of butted ti I've seen are the same thickness as PG frames at the end, and *even thinner* in the middle. Not thicker at the ends (as it were).

If COTIC built their frames using a 35mm seat tube and a 30.9mm seat post insert then I very much doubt that this frame would have failed in the way that it did. Another possibility is that the top tube and seat tube wern't mitred together very well(formed so they fit together properly without a gap)creating a weakness at that joint. That said the ti tubing might not be up to the same standards as the stuff that Lynskey probably use. I've never heard of one of their frames failing and they must knock out thousands each year.

[i]might not be up to the same standards as the stuff that Lynskey probably use. I've never heard of one of their frames failing[/i]

the Ti 456 dropout photo will be along shortly...

Just to add some fairness, I have cracked a Ti frame that wasnt the same manufacturer as the OP's. Mine was out of warranty but was still replaced by a (lower spec) frame FOC, I was happy with that.

the Ti 456 dropout photo will be along shortly...

???????????

MM very sorry to see this, it would be ironic to hear the old rock lobster Ti is still going strong. Epping was lovely last week - expecting a mud bath this week. Post up the conclusion.

Hey, glad you are still enjoying it 🙂

Epping was surprisingly dry last weekend! Hopefully have some news on the bike next week

MM

"All the examples of butted ti I've seen are the same thickness as PG frames at the end, and *even thinner* in the middle. Not thicker at the ends (as it were). "

Until some one cuts too much off the end of a butted tube (to make a smaller frame) and then, they are onto the thinner middle section of the tube. Which it looks very much like in the picture from Elliptic.

Titanium (titanium Alloys) can be subject to stress corrosion cracking (SCC)when exposed to alcohol (propanol).

This is similar to the effects of hydrogen embrittlement, and the effect of SCC from ammonia on brass, chlorine-ions on some stainless-steels.

Macavity - Member

"All the examples of butted ti I've seen are the same thickness as PG frames at the end, and *even thinner* in the middle. Not thicker at the ends (as it were). "

Until some one cuts too much off the end of a butted tube (to make a smaller frame) and then, they are onto the thinner middle section of the tube. Which it looks very much like in the picture from Elliptic.

You have x-ray vision? There's a stress riser there and we know nothing about how the bike was used vs its intended use!

I wouldn't repair it.

I'd expect a like for like replacement.

Too much seatpost? How tall are you and what size is the frame? If your 6f2 and running a 16" they could reasonably argue there...if its a 19" and 6ft2 for instance then you can say 'more impossible/why would I need to'

On a side-note, one of the ti frames shown on this thread- I found mine had a lot of flex and the reviewers love the frame for its ability to 'soak up the trail' on the DH's? Surely a candidate for a premature-end with all that 'flexing' etc going on around the welds etc putting stress through them?

Hora they could also say "the frame was sold with a 4 year 50% off warranty" 😐

Until some one cuts too much off the end of a butted tube (to make a smaller frame) and then, they are onto the thinner middle section of the tube. Which it looks very much like in the picture from Elliptic.

That had occurred to me also. My frame is (was) the "small" size with the mitred weld between the top and down tubes (on the medium/large sizes they don't touch and there's a short gusset under the top tube instead). So if the tip of the weld reaches the thin part of the tube..? just speculation though.

we know nothing about how the bike was used vs its intended use!

Standard issue trail riding, for the two years I owned it at least. Nothing stupid. When it broke it was (genuinely) JRA on a day ride in the Lakes.

I always thought the percentage tend to apply to accidental/crash damage. 😐 Oh well!

Until some one cuts too much off the end of a butted tube (to make a smaller frame) and then, they are onto the thinner middle section of the tube. Which it looks very much like in the picture from Elliptic.

Many frames are butted per tube length. I.e. 'small' frame top tube will have proportional butting and so will a 'large' unique to the tube.

So this cutting off of the butt is extremely unlikely to be the case or norm.

Mine is a LARGE frame with 4cm more seatpost in the frame than the warranty covers.

It shouldn't of happened and pretty pissed off that a 4yr old xc frame should do this. At the moment looks like I am minimum £500 out of pocket.

MM

Agreed it's not good.

"So this cutting off of the butt is extremely unlikely to be the case or norm"

Sorry, its only the medical profession that makes basic errors.

http://www.****/news/article-1267451/Surgeon-cut-patients-testicle-mistake.html

http://www.nursingtimes.net/whats-new-in-nursing/news-topics/ethics-and-law-in-nursing/nurse-switched-off-life-support/5020874.article

Point is Macavity you have only speculation on your side.

In the OP there is a picture of a cold cracking toe crack at the edge of a concave weld.

In the Elliptic picture (good picture) there is not just a crack but the edges of the crack can be seen to have been deformed outwards.

This looks very much like the result of movement (resulting from the crack) / impacting of the two side of the crack together and, a very thin wall thickness crumpling / deforming on contact with the opposing side of the crack.

This may have no relivance (sp) at all, but I cracked two aliminium frames and a steel frame, in exactly the same area and blamed the frame each time for the problem. After all this carnage I realised that the seat-post I'd been using all that time flexed back about an inch when I sat on is. It seemd as though the seat-post was the culprit in the end, not the frames.

J

[url= http://audaxing.wordpress.com/2010/08/17/goodbye-setavento/ ]Same Story here[/url]. I am going to get it welded, probably by Enigma. However the thing is that if it cracks once like this it's a sign that the tubing welds on the whole frame are somewhat dubious. So my best long distance frame is going to get downgraded to a single speed pub bike 🙂

In the photo from StirlingCrispin the horrible cut-finish suggests a laser-cut surface.

http://www.thefabricator.com/article/lasercutting/the-challenges-of-laser-cutting-overcoming-some-common-obstacles

"Laser cutting can leave a recast layer on the surface. Because lasers melt and burn some of the metal, remelted materials are deposited on the side of the cut edges and on the bottom of the cut. This layer of deposited materials is highly stressed and may crack, especially if it is an oxide. Although these cracks are small, they can propagate into the material, creating larger cracks. This is especially true of inside corners with small radii, where stresses are higher.

Cracks can be eliminated in certain cases with high-pressure nitrogen cutting. For example, titanium is extremely reactive to oxygen. Oxygen embrittlement can lead to micro-cracks, which are an important safety concern for users of titanium such as the aerospace and medical industries, in which long-term strength and avoiding fatigue cracks is critical. Using high-pressure nitrogen is often the solution. This method effectively turns the laser into a controlled welding machine, blowing molten material away with 160 pounds per square inch (PSI) gas.

"

In the picture from vorsprung it is interesting to see the difference in appearance between the same crack on one tube and on the other tube. On the right (of the picture) it is fairly / relatively direct / straight (as cracks go), but on the left it is more erratic and meandering.

Different thicknesses of tube? Maybe, maybe not.

So my insurance company have got back to me and offered a 2011 Cove Hummer frame as replacement.

I could probably push for cash and get another Soda but tempted by the Hummer.

Anyone ridden both to compare? I do like the Soda geometry. It fits me well.

MM