MegaSack DRAW - This year's winner is user - rgwb

We will be in touch

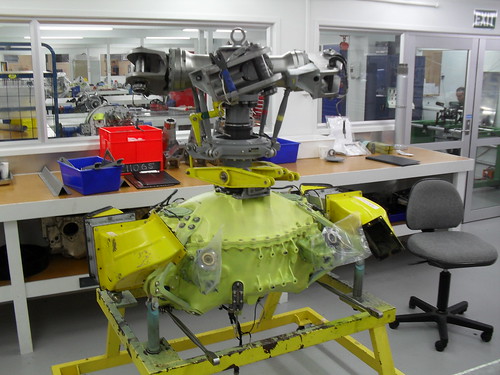

Some photos from work today. Given this forums penchant for a nice piece of Ti, I thought I'd share. That rotor star is a mahoosive titanium forging, bolted on to the transmission I've been building, for test on the rig.

On the stand in the shop.

[img]  [/img]

[/img]

With blades on the machine.

[img]  [/img]

[/img]

You've missed a bolt off in the middle pic.

Hopefully no trade secrets were lost in the making of this post 😉

it'a not a very aerodynamic chopper is it, do people who sit on the steps during flight get seatbelts?

p.s. why is there a park tool wired to it in the second pic?

Grass clippings look untidy & holes in runway need filling 😉

That one doesn't have wheels though. I'm sure the one with wheels would be better.

i dont know if i would feel less comfortable in a helicopter as several thousand feet[?], or a helicopter that desperatly WANTED to be at several thousand feet[?] and wasnt being allowed!!

Beleive me Olly, that thing shakes and rattles during a run. It sees full power, but isn't allowed to fly.

Would it work better if you put it on a big record player turntable?

How much lift does it produce compared to its weight?

(how much margin for safety)

Thanks for posting pics and good effort there ChopperT, good to see we still do great engineering in this country.

Can a helicopter take off from a freely rotating turntable? 😉

Lovely! Spent three years doing a Mat Eng degree and only really got interested when we covered Ti and carbon!

Sorry Piha, not in the UK! Graham, the tail rotor stops the turntable from rotating. 🙄

african or european?

Ooops, still good stuff though. Where are you in NZ then? Bit silly of me not to notice the Kowhais and Pohutukawas in the background of the airfield 😉

Antipodean innit iDave.

That grass needs scarified.

Why is it forged Ti? Just to make it expensive?

molgrips I think that light-weight is generally good for aircraft 😛

Forging aligns the grain in the metal and makes it loads stronger than a cast/billet machined part..

(i think)

I get to bolt this together MG, the engineering behind it is out of my scope, but I figure tinsy is on the money here.

Tinsy - pretty much bang on there.

But surely forging Ti is horrendously expensive? And yes I know forging is good, I meant why is it forged ti as opposed to steel or something.

Every kg saved on the build is a paying kg you can carry on each flight(hence the term "payload"). Over the lifetime of the machine, being able to carry an extra 20kg (say) on each flight justifies the expense of the Ti parts.

If that middle bit turns out to be substandard and not fit for purpose in any way, can I have it please?

In fact, have you got any bits of helicopters I can have?

Oh PLEEEEEASEE?!?!?

Join the queue, I'm looking for one to go on my mantlepiece too, thought I may have to enlarge it somewhat first. What about a set of blades to go on the verandah?

Mol - of all machines man makes, aircraft are probably most in need of the lightest, strongest materials of all. They use ti a lot - not to be flashy but because it's the best material for the job.

Beleive me Olly, that thing shakes and rattles during a run. It sees full power, but isn't allowed to fly.

You know when they engine test Harriers they rotate the exhaust nozzels downwards and tie the aircraft to the ground with chains.

Pretty noisy.....

What about a set of blades to go on the verandah?

Ooh yes please!

I'm serious; I collect all sorts of weird mechanical and electronic junk.

Good answer chopper T. In terms of economics it makes sense.

At least they've got a good ground-anchor to lock their bikes to.