Nice stool 👍

It is a nice stool.

Where do you get metal from everytime I consider trying my arc welder to splatter molten steel all over myself I get put of about the mad cost/hassle of obtaining tubes etc.

@kayak23 Thank you! Coming from you (I know your background) that's a massive compliment.

@joshvegas https://www.fhbrundle.co.uk

That's what I love about TIG; no splatter at all! I do have a habit of using flap discs to remove all the mill scale before cutting and welding for smaller projects, hence the shiny finish.

Ah that's much more like it!

A weewhile before I can afford cash and time but I'll book mark.

[url= https://i.ibb.co/hFkHVs8/IMG-20200112-082258181.jp g" target="_blank">https://i.ibb.co/hFkHVs8/IMG-20200112-082258181.jp g"/> [/img][/url]

A tandem, finally finished dry build at the weekend to see what was missing in terms of braze one. Now at the powder coaters, also made the fork.

Amazing tandem, man dem impressed. 🤙

Building a fuzz pedal from a kit. Had to relearn some of my high school science about electronics components and how to solder onto a PCB...

Hope to get it functional soon then think about painting the box. Also need to peruse a knob catalogue.....

Made a frame for a friend.

Finally got round to making an intertwined thistle and rose headbadge. I was going to san off the powdercoat and polish but given he wanted the frame army olive drab I thought I would leave it stealth green.

Also laser cut his name into the seatstay bridge. At least if it gets nicked it'll be easily identifiable.

Jon I think your original headbadge plan will look great at the moment it's kinda hard to see what it is.

Looks good though.

At least if it gets nicked it’ll be easily identifiable.

elementary my dear Watson

Been taking perfectly fine bits of wood and setting fire to them... 🔥

Looks good kayak.

Did you go over it twice to get it even?

My dad has to do a whole bunch for cladding and I don't think he has worked out the best way

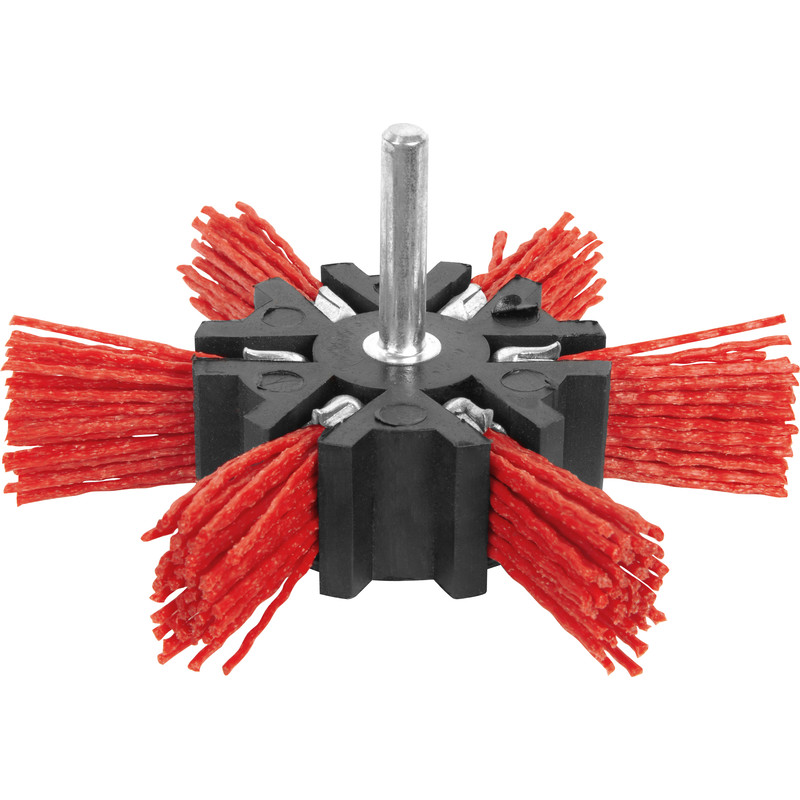

Yeah I went back over it here and there but brushing it back blends it all fairly well. I used a rotary brush on a drill along with a hand brush.

I think it depends what sort of stage of burn you're looking for. I know the big Shou sugi ban cladding suppliers use a fixed system, roller fed, so get a nice even finish.

That will look amazing as cladding though.

I used Oak here which isn't really the best to use as the contrast isn't so great between the grain texture, as say Cedar which is traditionally used.

It looks mint in the flesh though. Hard to photograph. 😊

Fuzz pedal finished wiring up.

Turns on and off with the footswitch, the LED goes on and off accordingly and makes a horrible (but expected) noise.

Success!

Love that breakfast bar Kayak, am thinking of doing this technique on oak legs for a new table, could it be done with a small gas burner (as in from a can, like a plumber would use) or would it be difficult / extremely tedious to get even?

Love the tandem.

Also the simple Oak table - (maybe you could plant another oak tree at the bottom of the garden to replace the old one).

Love that breakfast bar Kayak, am thinking of doing this technique on oak legs for a new table, could it be done with a small gas burner (as in from a can

Sure can. Weed burner heads are ideal as a plumbers torch can be too concentrated. But yeah, lots of folk use butane burners. Make sure you stick it on here when done 😊👍

jonm81

Nice detail work on that frame.

Like the background motorbike too. 🙂

Cheers Kayak, will give it a go. Have a big stack of Oak planked from a tree we had cut down a few years ago. It has been "seasoning" in the hallway for 5 years also....ALOT of planing to do until it reaches this thread!!

I'll say it first.......noice

what case is that if you don't mind me asking (for a friend)

Buying a house hasn't been great for riding but it will give me some stuff to post on here at least.

Made a mantelpiece out of an old bit of beam I had lying around to replace the gopping black marble-esque fire surround around our very-STW stove that came with the house.

The beam was quite dirty but I didn't want to remove too much "character" so I just cleaned it up a bit with a wire brush wheel on the angle grinder, and hand-sanded it a bit. Finished with a bit of beeswax/linseed oil mix (was hoping for a more subtle finish but hopefully it'll mellow a bit). Where I had to expose fresh timber on the ends in cutting it to length, I used a round ended cutting bit on a Dremel to pattern it. Used that technique before - bit tedious but I like the detail.

[url= https://i.ibb.co/9VY058C/IMG-20200206-132649.jp g" target="_blank">https://i.ibb.co/9VY058C/IMG-20200206-132649.jp g"/> [/img][/url]

Sick of missing the semi-random bin collection dates in North Yorkshire so made a Bindicator. It grabs the calendar from the council and lights up with the appropriate bin colour the day before.

You'll need access to a 3D printer, but if you want to make your own I've uploaded the source and STL files to github ( https://github.com/furstyferret-dev/bindicator)

Videos there too if you click the images.

I love the Bindicator, that is properly brilliant.

Flaperon

Sick of missing the semi-random bin collection dates in North Yorkshire so made a Bindicator. It grabs the calendar from the council and lights up with the appropriate bin colour the day before.

Wow - that's great!

Made some Swift boxes for Christmas presents and wanged a couple up today finally.

Merak

The case is brilliant, I'd love to have something similar.

I see the availability of the case itself, but how did you cut all the recesses for the tools?

The ones I see are all removable squares, you have managed to include curves etc..

My thought is that if I used a hot knife, I wouldn't get the straight lines and I would burn the foam.

Give us a clue!

Very nice! What are the holes chain drilled behind the curve for though?

Very nice! What are the holes chain drilled behind the curve for though?

I laminated the curve. The holes are to clamp to . Shown in this vid 👍

Oh wow! Proof you can never have too many clamps.

Had a look at your Insta and missed that, cheers!

A Relief Map of the Peak District.

See the 3D printing thread for more details:

https://singletrackworld.com/forum/topic/cheap-3d-printer-kits-experiences/page/17/#post-11071816

[url= https://live.staticflickr.com/65535/49609260592_9796a45752_b.jp g" target="_blank">https://live.staticflickr.com/65535/49609260592_9796a45752_b.jp g"/> [/img][/url]

[url= https://live.staticflickr.com/65535/49609257752_21c214eded_b.jp g" target="_blank">https://live.staticflickr.com/65535/49609257752_21c214eded_b.jp g"/> [/img][/url]

[url= https://live.staticflickr.com/65535/49609253877_e142306375_b.jp g" target="_blank">https://live.staticflickr.com/65535/49609253877_e142306375_b.jp g"/> [/img][/url]

Finally got around to making myself a new frame.

👏 That's amazing jonm81!

I made this

[url= https://i.postimg.cc/tJ1GG2CS/20200308-154559.jp g" target="_blank">https://i.postimg.cc/tJ1GG2CS/20200308-154559.jp g"/> [/img][/url]

Nice. Tigged? What tubing - I guess one of the pre-bent Columbus or 853 down tubes?

Edit - posts got jumbled - this was to jonm - questions for don are overleaf 🙂

Wow - framebuilder corner tonight! Don - was it you exhibiting at Bespoked the other year? Unfortunately I didn't go that year, but think we might have accosted you one year earlier when you were riding the road / folder version to the second venue in Bristol. That was my favourite bike of the whole show (even though you weren't exhibiting)!

Hey mick yeah that may be us! We had the orange and blue folders at bespoked.

That's amazing! Can't quite figure out how the drive axle gives you gears and a freewheel though - is it a custom hub?

Hey mowglie have a look for some videos on our page here... If you do Facebook. If not let me know and can try upload some videos here!

Thanks Kayak.

Mick, yeah columbus zona for the main tubes with headtube and dropouts from Paragon Machine Works. Main tubes are tig'ed with bridges and braces brazed.

I'm about to start another frame which will be built with a carbon Lefty into a light xc mile muncher. Hopefully have that one finished early next month.

Jonm81... Your frame looks awesome really good work. My TBike is also tig welded but with T45 tube.

Frame building is really satisfying 🙂 I love the colour too.

I have always wanted to build a bike with a lefty.... Perhaps one day I will throw one on my TBike for the ultimate weird build!

I love this thread it keeps on giving

Some great things since I last looked at the thread but the bindicator strikes me as the pinnacle of human achievement - you need to get marketing them ready for fathers day, no middle aged man should be without one.

From this....

To this....

Very nice axe. 👌

A pedal strike on DonCorleoni's bike would be a bit of a stopper.

@kayak23 - love the swift boxes, I’d like to put some like that underneath my gutters, there aren’t anywhere near enough swifts around now; it’s the real sound of summer for me, swifts chasing each other around the houses screaming their little heads off!

Not really a make, more a fix, hack and improvement.

I've got a couple of these little Fuji XP cameras. Love them for point and shoot work (and the fact that they have a Fujicolor mode for the nostalgia kicks).

The only thing I don't like about them (and it's a bit of a showstopper for me) is the plastic lens cover scratches really easily and fogs your pictures horribly. This happened to both of my XP130s and led to their early retirement.

Cue some fiddly disassembly, component removal, bonding and Sugru work. I've now got an XP130 with a 37mm filter mount on it, meaning I can just swap out the filter if it gets scratched. Might be a little less water resistant than it was but not much, and still better than a 'normal' compact anyway. The payoff is the ability to play with filters and the fact I now have (thanks to bastardising the two cases of the cameras I had) a nice stealth black camera rather than the garish colours the XP comes in as stock.

Might be the first of many crochet projects during this time...

[url= https://live.staticflickr.com/65535/49677536707_3c0e1ea324_z.jp g" target="_blank">https://live.staticflickr.com/65535/49677536707_3c0e1ea324_z.jp g"/> [/img][/url]

Ace - best thread ever!

Funnily enough, I'm busier with work than ever as some companies have got time to consider websites, rebrands, etc that normally they are too busy for.

So I might not be able to contribute much, but I'll be checking in eagerly looking for all your creations!

I made a small back pack and a messenger bag, really enjoying leather working at the moment, loads of stitching but very satisfying...

[url= https://i.postimg.cc/bGvJZyCq/IMG-20200315-104934.jp g" target="_blank">https://i.postimg.cc/bGvJZyCq/IMG-20200315-104934.jp g"/> [/img][/url]

[url= https://i.postimg.cc/S22xGZb5/IMG-20200318-162116.jp g" target="_blank">https://i.postimg.cc/S22xGZb5/IMG-20200318-162116.jp g"/> [/img][/url]

@mahowlett - where do you get the leather from?

Loving this thread - nothing I make comes close to the quality of things on here though!

I've been getting mine from metropolitan leather, the hide I used on those bags has a really nice oiled finish with loads of 'pull up' so the colour changes where you bend it, and it ages really nicely. Biggest problem with leatherworking is the cost of the leather though. Those 2 bags used nearly a whole 'shoulders' piece (16 sq ft) which costs £153 quid 🙁 you really don't want to screw the cutting out up.

love the swift boxes

Thanks. Yes we're really hoping that they get populated. I think you're supposed to play some Swift-Barry White or something to get them started.

Loving the frog ebygomm 😊🐸

Loving the frog ebygomm

It's a gecko, it has a tail! But thanks 🙂

I thought it was frog until you said it had a tail and looked again and saw it. Still like it though 🙂

That Gecko is so cute.

There has to be a market for selling them. Can I have a mini one on a keychain please?😉

It’s a gecko, it has a tail! But thanks

Ha! 😂 doh! Sorry. Lovely gecko. 👏

Great crochet! I feel this thread could get quite busy over the next few months. I made my first knife. Blade is from some broken garden shears and seems very good steel - had to get a special carbide drill to make holes in the tang. Handle is australian jarra.

I made a start on my picket fence, replacing the 70's concrete blocks:

Bit quiet on the paid work front with me at the moment that's for sure, but did a few extra bits on a Bongo camper van I'd made a boot jump for a while back.

Made an underseat drawer. Tricky to negotiate all the seat mechanism shizzle but was good in the end.

Also made a stow on the back of the seat for the portable table with birch plywood cam-catches to hold it in.

Well stir fever set in so we took the spare ride on mower (unused since the dog ate chunks of it), took off the cutter. Raised the motor a few inches so we could run the rear axle off the lower big pulley and we are working towards building temporary ramps on the garden terrace and we could make ourselves a 100m loop through the trees. If we still had the welder we could do a better job.

The motor is raised on steel tubes, the wood is only there to stop (or more likely minimise) the engine moving. Should be fun.

Thats got nhs strain written all over it.

Don't worry. We'll be wearing face masks.

Will you putting the fairing back on with racey cutouts for the bits of engine that no longer fit?

Its needs more flames too...

All going back on but raised higher. Checker plate tread areas pop rivetted on. Brakes being finely tuned.

Still safer the the 2 GSX-Rs in the shed.

Made a crappy monitor stand from some Capita legs and a piece of furniture chipboard I had lying about.

I can't use my usual workshop at the moment so improvisation time. I added an old vice that my Dad gave me which is more than 50 years old to a minibench I made. Still works good. Lets me carry on with latest canoe paddle.

Some other paddles and WIP pics

I had the same idea as you Ian, glued up the top for the table top bench lastnight for a crap vice i have. Should be usefull for some small yhings even when the full bench is built.

What woods have you Used in the paddles?

Now that I'm WFH and getting used to juggling phone calls, Whatsapp messages and calls and text messages a few days ago I made in my home workshop a project that kids make with me in third year metalwork. Sheet steel and square bar phone stand, except mine is TIG rather than flux-core MIG welded.