- This topic has 17 replies, 10 voices, and was last updated 8 years ago by rwamartin.

-

How to test new wiring before a room gets plastered?

-

dingabellFree MemberPosted 8 years ago

Bit of a weird one.

Have put in lots of new twin and earth wiring for lighting circuits in our new extension. Is there any way to check whether a wire is OK before we plaster because I’m worried that if there’s a break somewhere in the run, I’ll then have to rip the wall down to find it?

I was thinking maybe attatch a small battery to one end and a tester or something to the other and check the current is running through it OK?

Is this a stupid idea and am I worrying too much?FlaperonFull MemberPosted 8 years agoTemporarily link two cores at a time and check for continuity at the other end with a meter.

midlifecrashesFull MemberPosted 8 years agoAlso check you haven’t got continuity live to earth, live to neutral and neutral to earth. I have an old 5m lump of wire with a couple of croc clips which greatly assists in this as the leads on the multimeter are never long enough.

footflapsFull MemberPosted 8 years agoHighly unlikely you’ll have a problem that isn’t in a socket / light fitting. I wouldn’t worry about it.

trail_ratFree MemberPosted 8 years agoam i alone in being worried that someone whos run a load of twin and earth for their new extension is asking this question.

dingabellFree MemberPosted 8 years agoDon’t worry. I’m only doing the easy bits from a drawing done by a sparky friend.

I think I am probably worrying over nothing.

Have followed my instructions to a T.mattyfezFull MemberPosted 8 years agoIf you’re using the right gauge cable it’s very unlikely there will be an issue, unless it’s bent hard or around sharp turns.

Use a multimeter to test before the plaster board is put up to make sure.

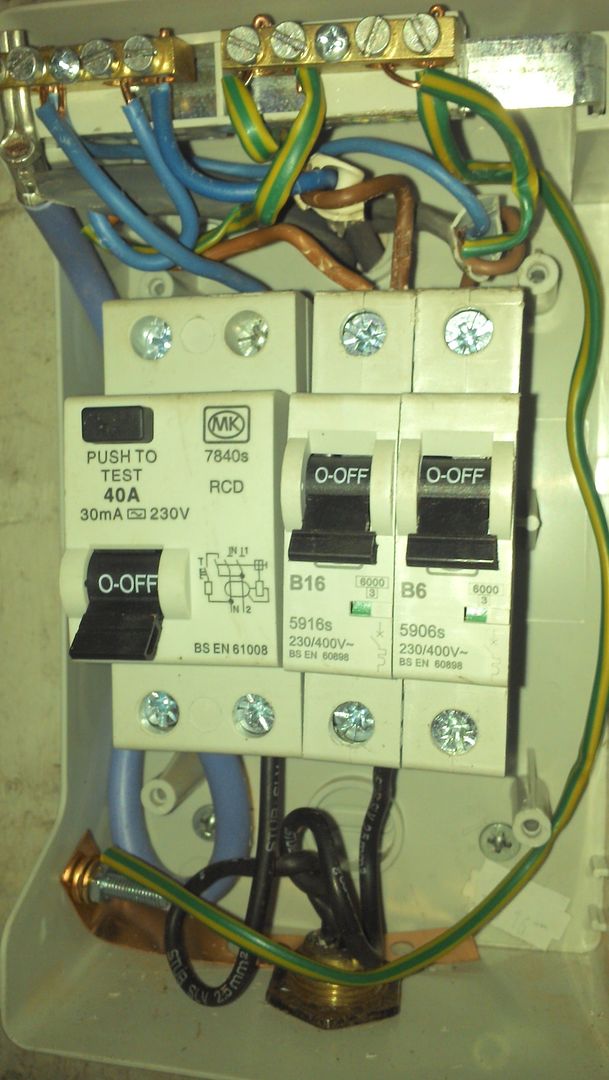

midlifecrashesFull MemberPosted 8 years agoI got called round to a mate’s house last week to help diagnose his sockets tripping the circuit in his new man cave. He was convinced a screw had found a wire when boarding out. Main power off at main isolator, we separated the ring out and worked our way along. Aside from maybe a loose neutral terminal on one socket, all seemed good enough, so I had a look in the mini consumer unit:

nickjbFree MemberPosted 8 years agoYou could do a continuity check but you shouldn’t have any hidden joints and if you’ve broken the cable I’d hope you notice so it wont tell you anything. More likely is damaging the outer sheath or wires not in the safe zones which will need a visual check and a bit of knowledge.

dingabellFree MemberPosted 8 years agoSlightly off topic.

I still have to pick up some led downlighters.

Are there any that are very good or are they pretty much all the same?

Was thinking just Screwfix or Toolstation ones?trail_ratFree MemberPosted 8 years agocant see your photo becasue of filter at work but what did your mate do midlife ? im curious now hahha

midlifecrashesFull MemberPosted 8 years agoBusbar was still in the cardboard box, live incomer to wrong side of main RCD, neutral incomer to busbar terminal of ring main MCB, neutral terminal strip connected to usual live incomer terminal, earth tab missing on armoured feed from house, bodged with copper meccano like strip, spaghetti, loose terminations and assorted clumsy insulation damage. Other than that it was fine.

dingabellFree MemberPosted 8 years agoThis is exactly why I never mess around with my C/U.

Best left to the pro’s.

Our old consumer unit was fitted with fuse wire it was so old. It never once tripped/ blew a fuse.

When we had the new one fitted it tripped straight away due to lights being wired wrongly etc.

How were the old type ever legal?timbaFree MemberPosted 8 years agoBorrow a copy of this from your local library, it details the tests, but you’ll still need someone to certify it all for building regs when finished

rwamartinFree MemberPosted 8 years agoUsual “tool” for the job is a multi function tester. You should be checking the continuity of the CPC (earth). This can be done either as an end to end test with a long lead, or what is known as an R1R2 test where live and earth are linked and continuity checked. Figures should be recorded for the electrical installation certificate which is required for new circuits.

Also you should do an insulation resistance check. This is done L-E L-N N-E and confirms that the insulation in good condition. You should see 1M Ohm minimum but usually it’s >100M Ohms when testing good cable.These tests are normally done after plastering but it’s not a bad practice to do so beforehand if time (and cost) permits.

Equally importantly a visual check should be made to confirm cables are in the correct zones etc. and a sanity check of the functionality to make sure you’ve actually run the cables required.

Light switches should ideally be no greater than 1200mm from floor level to meet building regs. If you’re thinking of fitting anything other than pendants it can be easier to wire “power to switch” rather than “loop in” to the ceiling as the connections are made in the switch box and fixing of light fittings is just 1 cable.

Also, I’d recommend 35mm back boxes (if you’re not using plasterboard boxes) as they will give more depth to work with, particularly if you choose to use anything other than dumb light switches. Leave the boxes about 2mm proud to allow the plasterer to skim to their edge.

Hope this helps.

Rich.

PS As mentioned above – no junction boxes which can’t be accessed for maintenance and inspection. All inaccessible joints should be permanent (ie crimped). Preferably no joints except at switches or in light fittings.

dingabellFree MemberPosted 8 years agoThanks for that rwamartin.

Very informative and helpful.

That’s why I love this forum.lerkFree MemberPosted 8 years agoI’d say you’re more likely to find damage after plastering – but then I’m a sparky and have to dig out the plaster from backboxes after the muck spreaders have finished… 😈

rwamartinFree MemberPosted 8 years agoNo problem. Just ask.

Lerk is right though. The damage is more likely to be caused by the plasterer’s sharp trowel than at installation time (plus kitchen fitters, plumbers etc.) so testing at second fix is the norm.Rich.

The topic ‘How to test new wiring before a room gets plastered?’ is closed to new replies.