- This topic has 24 replies, 9 voices, and was last updated 10 years ago by ir_bandito.

-

Building a rohloff / alfine bike, need advice on crankset options and ratios

-

flanagajFree MemberPosted 10 years ago

Thinking of building a bike with either a Rohloff or Alfine geared hub and am unsure what cranksets I should be looking at. I have seen some good deals on a 36 / 22 Truvativ X9 double crankset, but am not not sure of the following

1. Will the chain line work if I was to remove the inner ring and just the larger outer, or should you ideally go for a single ringed crankset such as the Shimano Zee?

2. How do you deduce what sized front ring / rear sprocket you need. I know what I currently have on my 3 * 9 setup?

I suppose that given you don’t have a rear mech if you spec it correctly you can get a perfectly straight chainline?

brFree MemberPosted 10 years agoGo Middleburn?

Single specific and lots of length options plus many rings.

bencooperFree MemberPosted 10 years agoYes, just keeping the outer chainring works perfectly with the Rohloff (and Alfine too I believe). The Rohloff even comes with spacers so you can use your existing chainring bolts.

If you want to experiment with gear ratios, try my gear software:

Around 40-44t is common with the Rohloff.

trail_ratFree MemberPosted 10 years agouse sheldon browns gear calc – put in what you have – work out the range

then work out what options of rings and sprokets will give you similar or something you can live with ?

my rohloff is fitted with an XT chainset with the chainring on the middle position but with a couple of thin spacers in the BB – ie its 68 and instead of a spacer on each side ive got thin ones and spaced the ring into the centre of the chainline – then used the left over thin spacers on the otherside to make the cups the same distance as previous.

what frame are you using ? if you go rohloff i suggest you look for one with a rohloff drop out , makes life so much easier than dog bones and torque arms. – if they are sliding drop outs see if you can get a swap out – my ragley TD-1 i was able to get a sliding rohloff drop out from lynskey 😀

trail_ratFree MemberPosted 10 years agouno – really …. if you love changing chainrings alot.

steel ring , steel sprocket and youll be rolling long after the uno has had 3 changes.

orangeboyFree MemberPosted 10 years agoJust like the clean look of the UNO set up

But tbh I do use a surly steel ring on the ss nowflanagajFree MemberPosted 10 years agoI am undecided on frame at present, but am swaying between either a Ti frame which would enable me to go for a sliding drop out for a SS type setup or a carbon frame with a hanger, which I would then fit a chain tensioner device.

Whilst happy to go for a double and just remove the inner chain ring, I don’t really want to go for the triple option and remove inner / outer and put a bash guard on. I think the bash guard spoils the aesthetics of the bike

trail_ratFree MemberPosted 10 years agoid be careful with a carbon frame and a rohloff with tensioner – youll almost certainly be running a speedbone or a torque arm and putting stress on bits that werent laid up to have that type of stress put on them

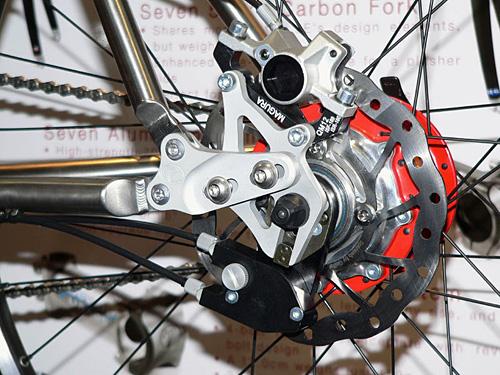

thats how mines looked when i built it.

– swapped the rohloff for a hope pro 2 SS in the end – I am faster on that.

bencooperFree MemberPosted 10 years agoyoull almost certainly be running a speedbone or a torque arm and putting stress on bits that werent laid up to have that type of stress put on them

Disc mounts are designed to take a lot more force than the Rohloff produces – but yes, the torque arm clamp isn’t a brilliant idea on a carbon frame.

simons_nicolai-ukFree MemberPosted 10 years agoFirst off – what wheel size are you building?

In my experience the Rohloff chainline is better using the outer ring (which always looks better on the crankset as well). Alfine chainline matches middle ring – originally commuter kit so Shimano’s Alfine cranks have a chainguide/protector on the outer ring position.

Cranks – really doesn’t matter. I’ve run XT, XTR, RaceFace and others. Running single ring does put more stress on the tabs so superlight cranks designed for double or triple use aren’t a great idea – I’ve broken the spider on a pimpy light German crank. Middleburn cranks running on my Rohloff bike at the moment with a single ring spider. Looks very neat but I did break one spider which Middleburn replaced without questioning.

Rings – unramped. Steel for longevity at expense of weight. I use Alu DH rings but you don’t need majorly solid rings and it’s not worth paying silly money. FSA are about half the price of some of the more fashionable brands

Ratios – will depend on wheel size and road vs off road. 26″ off road 38/16 is my default fit – you’ll get up nearly anything with that but spin out downhill on road. Rohloff have altered their minimum ratios (I suspect in response to growth of 29ers). Katie’s currently running 34/16 which is great if you like to spin up big long steep climbs (very nice out in the Pyrenees). I like super low ratios – my Pinion gearbox has a lowest ratio about the same as the 34/16

flanagajFree MemberPosted 10 years agoThanks for pointing that out regarding the chain tensioner on a carbon frame. Are you saying that it is the mech hanger that is questionable or the carbon layup. Only reason I ask is that I may also consider an aluminium frame. Like everyone these days I am trying to build it on a budget by shopping around and picking parts that are on offer.

It’s a 29er I am looking to build.

trail_ratFree MemberPosted 10 years agoon an alfine youll be fine i would think

but with a rohloff its not just a case of fitting a tensioner and everything else will work.

ill go find pictures.

trail_ratFree MemberPosted 10 years agoif the disk mounts like that you could get away with that – but i wouldnt be surprised if you did see a failure in the bonding – as ben says they will likely be fine but the constant cycling might see failure long before it would have done with just the braking forces acting on it.

If you can get it – a drop out similar to this is imo the best option for rohloffs no **** the dog putting the wheel in and out – drop it in , screw on click box and go. It is for me the major reason i still have my rohloff instead of my alfine 😀

mrchrispyFull MemberPosted 10 years agoThe words rohloff and budget don’t really go together do they?

flanagajFree MemberPosted 10 years agoWhat is that lever jubilee clipped to the stay?

The words rohloff and budget don’t really go together do they?

Well spotted, but let’s gloss over that for now

bencooperFree MemberPosted 10 years agoThat long lever is the torque arm – it’s used on frames which have neither a Rohloff-specific dropout, or a disc mount. Clamping that to a carbon stay would in all likelihood be perfectly okay – carbon is much stronger than you think – but would be sub-optimal.

If the frame has an IS disc mount, then you can use the Speedbone onto that instead, and I’ve never, ever heard of a problem with that on a carbon frame. If a carbon frame was so weak that relatively small loads through the disc mount caused it to fail, you’ve got bigger problems.

Thanks for pointing that out regarding the chain tensioner on a carbon frame. Are you saying that it is the mech hanger that is questionable or the carbon layup.

No problem at all with the tensioner on a carbon frame – again, if the frame can take a derailleur then it can take the tensioner, which puts a lot less force on the mech hanger.

trail_ratFree MemberPosted 10 years ago“If the frame has an IS disc mount, then you can use the Speedbone onto that instead, and I’ve never, ever heard of a problem with that on a carbon frame”

what about other frame materials ? – NDS chainstay failures seem quite common in rohloff users in steel, ti and alloy

Cyclic loading much more frequently where frames were not designed for it. I agree it might be fine BUT im pointing out that very very few carbon frames were designed with fitting a rohloff in mind

carbon is better than most materials for resistance to it but its not infallible , depends on the frame design as well , most of the time i see alloy drop outs bonded to the carbon for clamping , especially on the cheap carbon frames since we are on budgets and its the bonding of that to the carbon id wager on failing rather than carbon

simons_nicolai-ukFree MemberPosted 10 years agoIt’s a 29er I am looking to build.

I’d be on 34/16 in that case

bencooperFree MemberPosted 10 years agowhat about other frame materials ? – NDS chainstay failures seem quite common in rohloff users in steel, ti and alloy

Really? I’ve been fitting Rohloffs for 15 years, and I’ve never seen one. The only issues I’ve seen have been people using the OEM axle ate that’s not designed for it – track dropouts for instance.

mochaFree MemberPosted 10 years ago@trail_rat. That pic of the Surly – did you have to unbolt the disc mount to remove the wheel? Just fitting a Speed hub to a Krampus – same dropouts I think.

trail_ratFree MemberPosted 10 years agolooks that way – its not mine i have no idea , tbh i was looking for a speedbone mounting and missread that picture on my phone … i would reckon he has to remove that bolt. doesnt seem like the most clever fitment to me.

bencooperFree MemberPosted 10 years agoNo, that’s a Monkeybone caliper adaptor – the OEM2 mount slots into it a bit like a Speedbone. So you don’t need to unbolt anything.

ir_banditoFree MemberPosted 10 years agoI use a Monkybone adaptor for my Rohly,tidiest looking way of doing it by far. I’m about to switch the cables around to use V-brake noodles for a better line too.

For a while, I was using a Speedbone on a Cotic Simple. That[/t] was a right ball-ache to get the wheel out, had to loosen the brake bolts, undo the axle, slide the wheel forward, knock the chain off then pull the wheel back out.

As for gears, I’ve got a 38t ring, mounted on the outside of an XT triple chainset.

When I had an Alfine on another bike, I flipped the cog over to give a 47.5mm chainline. Then used my old Middlebeun RS8 cranks with the ring in the outer position, on a 110mm axle, gave a perfectly straight chainline.

The topic ‘Building a rohloff / alfine bike, need advice on crankset options and ratios’ is closed to new replies.