MegaSack DRAW - This year's winner is user - rgwb

We will be in touch

Folks, the benefit of your collective wisdom please. Our underfloor heating doesnt seem to playing ball at the moment. It heats the downstairs (obviously), but seems to be heating only our guest room and ensuite, at the far end of the house. Our lounge, kitchen and utility are not heating at all, the floor remains cold. Thermostats are set to 20C..it doesnt make any difference where we set them, nothing changes. The boiler is a Combi, with the settings for the heating at 6 (out of 9 settings) and again, it doesnt appear to matter where its set at, the above areas remain cold. Hot water is being produced without issue.

Ive had advice from a mate of a mate that underfloor needs leaving on permanently to work, which sounds like bollocks to me, is this correct? The thought of it blasting away from now until kingdom come fills my bank account with horror. As we are in and out at various times, we have it set to turn on and off at the usual times (0600 - 0900, 1100 - 1400, 1700 - 2230).

Anyone help us out, either professionals, or anyone with a similar problem resolved?

UFH has a reaction time between something like 12 and 24 hours depending if you have slab underneath or on top of the insulation. But regardless it a thermal mass heating system not a radiator(technically they are convectors not radiators), you have to keep it warmed up to work. The idea is to use low grade heat (30 to 55 deg depending) rather than the 60 deg that rads need to 'blast out' enough heat. Condesning boilers stop condensing at about 55 deg.

However sounds to me like you are not getting any flow to parts of your system, check the distribution maniflold isnt closed off etc, otherwise get someone in to check it.

As above, UFH pipes are embedded in 2" of concrete, water is at blood temperature but is tempered down to this beyond the boiler. Since pipes are plastic and 15mm, they are unlikely to block. Different zones may have seperate pumps and timer channels; is something out of synch there?

Room stats only need to be at 17c as the heat is round your feet (where you need it!).

I have mine on from 6am to miday then 5pm till 1am. The boiler barely ticks over most of the time so it shouldn't hit your gas bill.

wot sug sed ^

check manifold valves are balanced correctly. And run it at 40deg ish for 6hrs.

Check manifold(s) as it sounds too localised to be a warm up problem (could be wrong)

Actuator could have failed, ports could be blocked.

Cheers all, ive just had a fiddle, and the thermostats dont 'click' (turn on?) until they are set to 23C...is this right? If not, anyway of lowering this?

do you have thermostatically controlled manifold valves or manual ones like lockshield valves?

what are these "thermostats" of which you speak? How many? Where? Attached to what? How?

Bi metal switch probably.

If its not clicking until 23 deg, it thinks it's 23 deg in the room.

Without looking at it, I don't know if you can calibrate it.

Stoner - not a scooby tbh. There is a bunch of valves and pipes in a cupboard tucked away in a recess in the lounge. There are 3 wall mounted thermostats, one in the guest room, one in the lounge and one in the kitchen, each with temperature dials...which seem to 'click' when i tuern them to 23C.

can you take a pic of the manifold?

I assume then that you have room thermostats that open or close motorised valves on your manifold.

as wrecker says, if the bimetal strip is responding to "23degs" then it's either 23 degrees in your house or you thermostats are a little out, in which case set them to, say, 18degrees + 23degrees - current temp.

that mass of pipes, feel them, are there some hot and some not?

Hmmm. I see you have stats in the kitchen and lounge, which means that they are probably not controlled by the same valve. Does the UFH heat up when the stat is made?

BTW - I bet you can pull the dial off the thermostat and push it back on at a different rotation to zero it.

Good thinking stoner, although many have stops I think.

I think the stop would be on the stem/controller not the dial face wouldnt it?

d'You reckon independant motorised valves on the manifold controlled by room stats?

right.

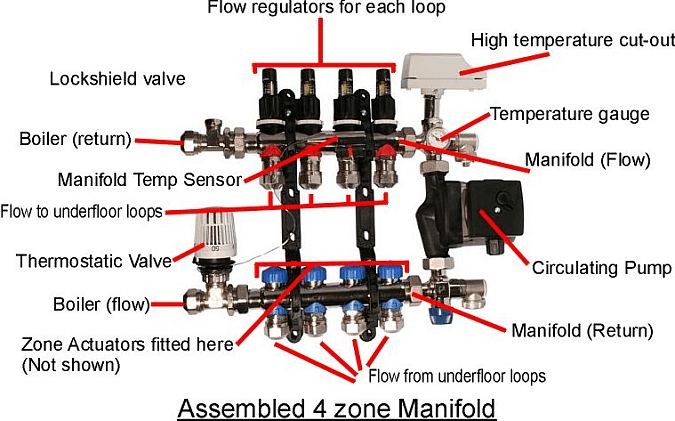

looks like 6 zones, (6 grey cables). If there are only 3 thermostats then I assume that there are 2 zones per room.

uponor motorised valves

Why is there a thermostatic valve on the supply side? Is it a crude "mixer" as opposed to a flow and return blending valve? That white twiddly thing on the left needs to be open, i.e. the air temp needs to be below the setting to allow hot water to flow to the manifold. seems a weird place to have one.

To check everything is working, turn the three thermostats up high so they switch.

Turn the white twiddly thing up high so its not restricting flow and then check that whatever is controlling the flow pump (white wire to the grey pump) is turned on.

You should see the flow gauges (black towers on the top of the manifold) all showing a flow rate to each zone.

* whats written on the piece of wood?*

The wood just identifies where each pipe supplies..2 for utility/kitchen, 2 for lounge, 2 for guest room/ensuite.

Thanks for the advice, i'll try your suggestions and see how it goes.

wtf is that TRV doing? blending valve is top right stoner, above the pump.

check the flow rates as said and just feel the pipes. if they;re all hot, then you have one of two things.

1) blockage, unlikely

2) the thermal mass the pipes are in is not having enough time to warm up

blending valve is top right stoner, above the pump.

you sure?

looks a very odd one.

ANyway, I still think that TRV is in an odd place.

i reckon so, think the knob is missing. not sure what the small box is

just seems odd to have the "box" so far away (3" above) the valve

no idea hat that box is, looks out of place. only 15mm flow and return from/to the boiler also

[b]Don't turn the thermostatic valve up on the left[/b] it is how the water temp is managed by the underfloor. Turn it up too high and you will cook your floors possible damaging coverings and it is also unhealthy.

Is should be set according to your floor type.

I assume the underfloor has been working ok? If so it is something that has changed, usually an electrical component gone wrong, open up all the room thermostats and see if the heads open on the manifold. You should be able to tell because the window on the gauge on the return manifold will show a flow rate change.

Turn the room thermostats as high as they will go to make sure they are calling for heat. Remove cover and check with a multimeter to see if they are sending a signal.

Check to see if you have a supply to the manifold pump.

Check manifold pump is rotating.

Investigate the manifold junction box if nothing obvious has been found yet.

The system pump (in the boiler probably) could push the water round one u/floor loop but is probably not man enough for the whole system hence checking u/f pump.

You could have air trapped in a loop or two.

You could always ask a plumber who knows a bit about u/floor to have a look, most of the manufacturers have a recommended list for a certain area. Happy to help more if you like.

mail me at timATj-twren.eclipse.co.uk

the more I look at it the more I dont get why that pump is where it is...

am I going mad?...

I believe that box on the left is also some kind of thermostat. Worked on one of their systems for the NHBC a while ago (also fault finding on it). Will look out details as think I took some notes.

probably doesn't matter, but shouldn't the TRV be on the flow side if it is performing that function? I don't see how it could possiblt contol the flow temp in any case, isn't that what blending valves are for? esp on ufh systems

Don't turn the thermostatic valve up on the left

[s]so it's not an air thermo valve, but a water thermostatic valve then?[/s]

well thats just silly. Im not thinking.

how do you know it isn't on the flow.

think the box on the right hand end is an overheat stat.

good point (smartarse) 🙂

then whats blending the supply heat down to useable heat.

That trv isnt doing it.

yeah, get a man in.

has it ever worked properly?

Yup it has a capillary with a probe on the end that should be connected to one of the manifolds. It doesn't blend it limits the available water temp. A lot of manufacturers use this method, nice and simple, cheap and easy to repair.

A thought the overheat could have tripped if the control valve has been turned up / capillary dislodged.

I believe the overheat stops the underfloor pump (system pump would maybe make one loop work as i mentioned earlier)

ah, so the capillary link is replacing the air temp function?

Much prefer a nice mixer valve myself 😉

Anyway, I think we're all agreed on the method to identify which bit isnt working.

all thermostats on, pump on, check for flow rate in each zone. then work from there.

Stoner - I have used David Robbens systems for ages now, they used to use mixers, got rid of them as uneccesary and another valve to go wrong.

I've tried other companies but they have been a great company to work with, I even get to try out some new things for them on some of my projects sometimes!

Oh and just fitted a 35kW Windhager biomass on a job, know you like your pellets!

(was bloody heavy!)

35kW Windhager biomass on a job,

(was bloody heavy!)

no shit ! 😉

another valve to go wrong.

same could be said of the TRV 😉

Ill get a pic of my manifold etc up tomorrow. Mines much dumber as I dont need zonal control and it has a thermal store supply.

Look familiar?

[url= http://www.gasapplianceguide.co.uk/UNIPIPE%20Manifold.htm ]More info.[/url]

TRV is on primary boiler flow circuit not UFH secondary.

At risk of oversimplifying, I don't suppose it could be anything as simple as an air-lock could it? Just a thought, but UFH systems can get them. If so a quick flush through could sort it?

I'd have a look at the pressure gauge on the boiler, may indicate a water loss resulting in air.

aha. I get it now.

Still cant help bu thtink it's rather less intuitive than a return mixing system...

This is mine.

[img]  [/img]

[/img]

Honeywell CM927 controlled relay on the left controls the pump on/off.

6 ground floor zones balanced for comfort levels manually.

Mixer valve set to 40deg ish. Hot water from centre of thermal store (anywhere between 40deg and 70deg) is blended down with return water from the UFH, the rest goes back to the bottom of the thermal store.

The thing I think is strange on the OP system is having a 2 port valve (TRV) on any system that is a constant volume system. i.e. fixed speed boiler pump. What if all the TRV's are closed it'll be pumping against a dead head. Still it appears to be a standard set up, maybe they have a pressure regulating valve in the system......or I'm looking too hard at it in a large commercial system point of view, I'd have inverter speed controlled twin pumpset controlled on a DP sensor for that system :D!!

constant volume system

Wouldnt the pump be on the same circuit as the room stats? so that pump will only run if at least one valve is open. As long as one UFH circuit is open, the inline TRV on the flow side can still be closed and there would be no dead end.

Yeah I suppose the pumps are small and don't mind if there's a large flow (all underfloor legs open) or only a small flow from 1 underfloor leg (worst case). On large 2 port systems the pump speed matches the system flow, as the valves shut the pump slows down, older systems were 3 port with a bypass leg with a balance valve that matched the heater coil resistance!

EDIT:

As long as one UFH circuit is open, the inline TRV on the flow side can still be closed and there would be no dead end.

I was kind of thinking from the boiler primary pump if all the TRV's are closed.

Good u/floor systems will only call for heat when the water temp is demanding heat, therefore pump only comes on with demand.

Also better systems use variable speed pumps, usually Alpha + on them.

bloody expensive those alpha +

was toying with using them in the barn (I have 3x 15-50s) but at that price ...no..