https://www.newmotionlabs.com/

Is there any sound engineering behind this at all?

Claims that it is the "biggest breakthrough in mechanical power transfer in over a century" or that it "enables conventional chains to transfer power on both sides of the tooth" look like a joke. Especially when they provide no evidence to back it up.

Even the award they have won just looks like a copy & pasted press release. https://www.fietsawards.nl/inzendingen/enduo-cargo/

All in all, it looks like a marketing and web design team have been told to make something out of nothing, and this is what they came up with.

Single speed only? I'm oot

Single speed only? I’m oot

*Sad Rohloff noises*

So the idea is double the thicknesses, half the teeth? Meh, the advantages aren't super well communicated. Reduced wear through less contact? Fewer losses due to the same? What are they really claiming?

Clearly snake oil. No images/video of the things in use on their site.

Don't be so dismissive - we (NPL - UK's independent national metrology lab) tested it and found "a consistently higher efficiency than the Shimano sprocket"

NML are claiming this results in a 1% efficiency gain compared to a Shimano sprocket at 400-900watts

I don't know how the efficiency changes at lower power levels, I'd guess the rise/fall isn't linear? It doesn't sound like there's a lot to be had at 150-250W of a longer ride though. One for the track sprinters.

Any increased durability or reduction of chain elongation through wear is more interesting to me.

OK, I'm intrigued now, although this does lead to several new questions.

First of all, that article is a load of "...was said to be...", "...claimed efficiency and durability gains...", "...claims this new...", "...is claiming up to...", "...claims this leads to..." all strung together.

Why don't they mention the NPL testing on their web site?

They claim to have installed 'The world’s first independent high accuracy, multi-torque transmission efficiency test rig' at Bath University. Is that apart from the one used by NPL? And the various ones that have been used to test the efficiency of hub gears and belt drives etc.?

Never trust a graph that doesn't start at zero.

Doesn't every chain and sprocket do something similar to this? Where does the next roller on a conventional chain and sprocket make contact if not the same place? It could do with more explanation.

As I understand it, chains 'stretch' unevenly. The narrow links 'stretch' less than the wide links. This could have a significant effect on their 'dual engagement'.

Is 1% significant, or within expected tolerance? I'd like to see the tests done with normal chainring and sprocket sizes at normal pedalling cadence. Until then, I am suspicious that they chose an optimum set up.

Are the NPL test results published on line?

Is 1% significant, or within expected tolerance?

The Cycling Tips article says the NPL test showed 0.2 - 1% gain in efficiency, accuracy of the rig +/- 0.1%

Doesn't sound significant to me but it would be to an Olympic track team, and an Olympic track team using them has good marketing value.

30% better wear resistance sounds good but I expect it's more than 30% more expensive than an average SS drivetrain.

The article is from a 'magazine', not the company's own. I'd expect a journalist to report claims as such, wouldn't you?

Is the Bath Uni rig separate? I wasn't personally involved in this testing, we have nearly 1000 scientists at the lab, was just aware it had happened because folks know I'm interested in cycling. I *think* the Bath Uni rig is a set up for prototyping and development, the NPL rig is for independent measurement, that's what we are commissioned to do in these projects.

Why is NPL's report not published? It may be, I've got a day off today so can't get into our Knowledge Management System, but I'll have a look tomorrow. Some reports are confidential to client as eg. may contain tests on other prototypes that might give competitive advantage away. Incidentally I know of several other cycling-adjacent related tests that have been done that are not public domain but very interesting.

Graph not going to zero.... what will it tell you, that at zero power there's no difference? You can see both the angle and convergence as power drops anyway, and I believe the test parameters are selected to represent 'real life'

So to that. I believe (again, was not involved) the market is track cycling where these sorts of rpms AT THE REAR are typical.... sth like a 5:1 ratio at 80-120 rpm is therefore 400-600 rpm at the back. 0.2-1% and the link states confidence at +/- 0.1%, so not huge but in the rarified air of elite level cycling, significant. Couple of seconds in a 4km team pursuit....yes please! And while your comments on wear etc , are fair, when you're in the area where fractions of a % matter, stuff doesn't wear out.

Never trust a graph that doesn’t start at zero.

also, they chose to test at 480 rpm. Why the bloody hell did they do that?

Never trust a graph that doesn’t start at zero.

also, they chose to test at 480 rpm. Why the bloody hell did they do that?

Edit: answered by jonv as I was typing.

As I understand it, chains ‘stretch’ unevenly. The narrow links ‘stretch’ less than the wide links.

Chains don't stretch, the pins wear and the chain gets longer. Each pin is located between a narrow link and a wide link. I do not understand what it would mean for the links to "stretch" differently.

As far as the Enduo chain goes, chain wear on singlespeed chains is much less of an issue - you can run thicker sprockets and wider chains. Making a chain narrow enough to work with a 10, 11, 12 speed derailleur system will always mean that it's not as durable.

and not sure how that reduced teeth sprocket would be made to shift. Could still work with hub or gearbox gears, but they're 'mainly' for reliability and then the issues of longevity could be a factor. And also is 0.2-1.0% that important for touring. Like I say, I think primary market is elite track

thols2, that's why I wrote 'stretch'. Everyone knows it's not an accurate description of what's happening, but it's a commonly used term.

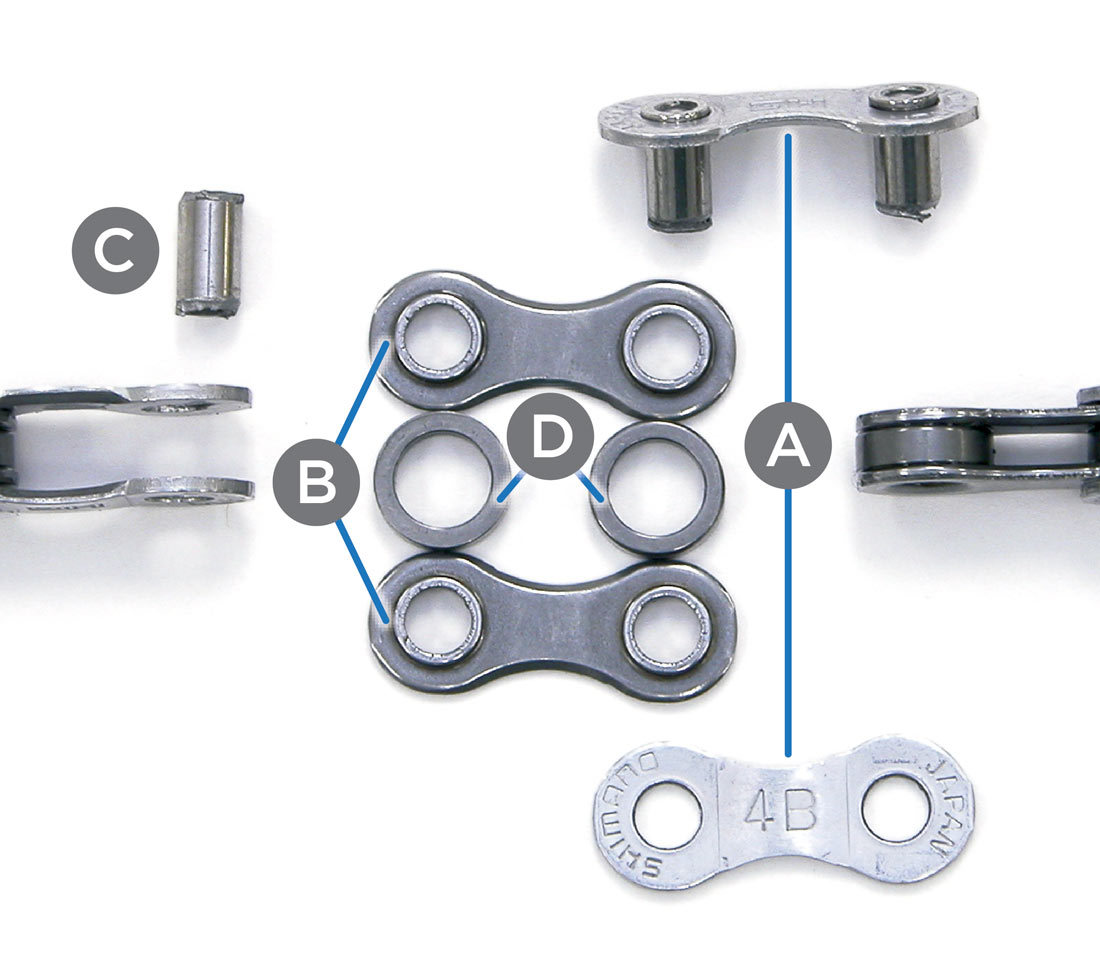

Not the best illustration, but as the individual parts of the chain wear, the distance between the two rollers on any narrow link stays the same.

However, with increasing wear, the distance between the two rollers on any wide link will get longer.

This becomes apparent if you run a single speed or hub gear with an even number of teeth on the sprocket or chainring and move the chain round one tooth. The teeth will wear alternately, so if you take the chain off and put it back on without checking, there's a 50% chance it will be horribly noisy.

IIRC removing alternate teeth used to be done on (motor?)bikes for speed purposes as it does reduce friction a little. However the idea that any load is taken on the front edge of a tooth sounds like nonsense to me as the chain will be pulled away from it.

theotherjonv, I would expect a good journalist to make it clear that they are reporting a manufacturer's claims, it just would have been nice if there were a few "independent tests showed that..." thrown in there as well.

At £200+ for a chain and sprockets, and quoting performance figures at 400w and 480 rpm, this does look like something best suited track cyclists, while being marketed to real world cyclists.

Perhaps they should offer a motorcycle version? I'm sure the top teams would think nothing of spending £200 on a 1% power increase.

What's the mechanism for the efficiency improvement? Don't all chains have this dual support thing going on? Is it just that there's generally less friction with less teeth and that thicknthin rings have highlighted that the thin teeth aren't really doing much so they've eliminated them?

Can anyone see what's special about the chain? The links suggest it's new and novel but don't appear to spell out why.

Chain's haven't been built like that for ages, modern chains the inner plate is pressed so that the holes are a convex cone shape, then the roller sits on those, the roller doesn't contact the pin.

My first assumption was that they'd taken narrow/wide to it's obvious conclusion and made the wide large enough that it pushed against the plates of the inner link rather than the roller, which I guess would decrease friction as then you only have the inner plate pushing against the pin, rather than roller-inner plate-pin.

But that doesn't look like what their video is suggesting.

Awaits the reintroduction of inch-pitch chain? Cool 🤓

Thanks, thisisnotaspoon. Now you mention it I had noticed that modern chains are different to old ones, but I'd never really looked into it before.

The principle is the same though. No matter how much the chain wears, the two rollers D, on plates B will always be the same distance apart. As the pins on plates A and holes on plates B wear, the rollers on plates A will move further apart.

What this means for their 'dual engagement' is that it will only work if the teeth line up with the narrow links.

If you put the wide links on the teeth, they will 'stretch' as the chain wears and any supposed advantage will be lost.

And the various ones that have been used to test the efficiency of hub gears and belt drives etc.?

i wouldn't trust any of the ones used to measure that tbh.

Real world use revealed them to be horse shit graphs.

like nonsense to me as the chain will be pulled away from it.

at various points in the stroke - thats not true.

Not the best illustration, but as the individual parts of the chain wear, the distance between the two rollers on any narrow link stays the same.

However, with increasing wear, the distance between the two rollers on any wide link will get longer.

So narrow-wide sprockets ensure that the chainring wears evenly with the chain (Since 'inner' links are always paired with the 'narrow' teeth and vice versa)?

If only they weren't made of low-grade aluminium they should last forever.

When my chain rings look like the new ring on these It's usually cos it's knackered. Have they been skip diving?