One engineer’s home-stretched suspension

With the earliest mountain bikes assembled from bits and pieces from all sorts of cast-off bicycles and motorcycles, often modified to suit, bodging is a proud part of mountain bike history and culture. When Magura engineer Reiner Kuenstle wanted a suspension fork for his fatbike, he couldn’t see simply ordering up another brand’s offering. No, he decided to modify a dual-arch Magura TS8 29er fork to accept his 135mm hub and 26x4in tyre.

Shown below is the process used to create Kuenstle’s first effort, a second was started this week. One of the major goals in this unsanctioned project was to see if it could be done at home, without the need for special bonding or laminating tools. The short answer is yes, the long answer follows…

- Laying the groundwork (and using Magura CAD data to ensure a precise fit), a pair of aluminium inserts were designed to follow the inside contours of the arches while adding 35mm in width. A wider crown was also drawn up and the parts were machined on a multi-axis CNC mill.

Custom metal - No doubt following multiple measurements, the magnesium lowers from a standard MT8 29er fork were split down their centreline.

There’s no going back now - Using a dummy front hub and the new, wider crown/steerer assembly for spacing and alignment, the conforming aluminium inserts were bonded into the fork’s bridges using common two-part epoxy. Reiner has said that the inserts and epoxy provide the majority of the legs’ rigidity; who are we to argue with the project’s engineer?

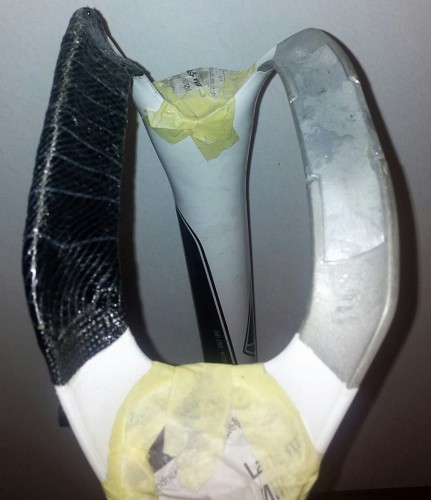

Glue sticks used as spacers (not adhesive). - Bring out the carbon! Once the inserts were cured in place, the arches were wrapped in standard carbon fibre at varying orientations for additional support.

It wouldn’t be a 21st century bodge without carbon fibre - The carbon fibre wrap used an aerospace-proven resin that reaches full strength after a long cure at room temperature, chosen to avoid damaging the already-coated lowers. The bushings remained in the legs throughout and a the tied-off innertube ‘sausage’ ensured good contact between the carbon fibre and extended arches.

Inner tubes: still useful. - Ordinary auto body filler was used to cover the carbon fibre and smooth the arches- the most time-consuming part of the process. Once smoothed to satisfaction, the filler was sealed with resin.

Smooth, but not yet attractive. - Standard white paint was used to cover the modifications and blended with the lowers’ existing powder coat and dried in the open mouth of the Kuenstle household oven.

Beauty - Wide stance aside, the fork was reassembled in the normal fashion. Without a close look, it would be hard to tell this fork from a factory product.

The same – but different

For his second go ’round, Reiner plans to use woven carbon fibre tubes to wrap the arches, which should cut down on the smoothing and filling work time. All in all, this looks like a well thought-out and cleanly executed project, calling it a bodge really doesn’t do it justice.

For those chomping at the bit, now that the concept has been proven Magura is working with composite suppliers to determine the feasibility of series production, more on that when we know. Many thanks to Reiner Kuenstle for the details and photos.

Comments (14)

Leave Reply

Post Comment

ace.

Nice piece of work, but I’m at a loss as to why a fat bike would need suspension. I thought the whole idea of the mahooosive rubber was to remove the bumps?

why? to see if he could do it.

Removing bumps isn’t the idea of fat bike tyres.

thats a tidy job, very impressive work.

No spoons?

Amateur.

That is superb.

Superb pro-bodge 😀 …but he could have saved a lot of time, money and effort using a maverick sc32 with 29er spacers fitted. better clearances too.

Wish I had a CNC milling machine “at home”

“One of the major goals in this unsanctioned project was to see if it could be done at home”

followed by

“using Magura CAD data to ensure a precise fit”

and

“A wider crown was also drawn up and the parts were machined on a multi-axis CNC mill”

That’ll be a ‘No’ then.

Unless you’ve got a very well equipped kitchen.

I’m going to have to knock half a point off for wrinkles in the duct tape in picture 5; Herr Kuenstle is clearly German rather than Swiss.

The Pinkster – I’m assuming they meant “assembled at home” – i.e. they could sell you the parts.

“The Pinkster – I’m assuming they meant “assembled at home” – i.e. they could sell you the parts.”

Does this include the tooling to press the crown off and on? Nice project but tough to replicate. Proper “because I can” stuff.

“he could have saved a lot of time, money and effort using a maverick sc32 with 29er spacers fitted. better clearances too.”

yes, but it would have been shit.