- This topic has 2 replies, 2 voices, and was last updated 12 years ago by DrP.

-

Replacing the bearings on a Meta 5 – a quick "how to"…

-

DrPFull MemberPosted 12 years ago

I know a few here have Metas, so thought this might be of help?

Yes, it’s a bit longwinded so if you’re not interested in this, look away! It’s just that a few searches bring up the question, so thought I’d help! It’ll be on the COC too….After getting some bearings for the Meta for christmas, the chance came to actually replace them whilst the little’un napped yesterday!

I had a look on the Com. Owners Club, and there seemed to be some people having trouble getting bearings out, getting the swing arm off etc.

All these people seemed to be using hammers and screwdrivers to ‘smack’ the bearings out, which then resulted in broken frames and sore knuckles!

Firstly, I’d say that this is a pretty poor way of removing bearings! The ones on my 08 meta were pretty tight in place, but shifted using a suitable home-made puller and a table vice.The home made puller is in fact my homemade headset press (I don’t have a specific photo, but it’s simply a 30cm long piece of M8/10 threaded rod, with 2 M8/10 nuts, and a pair of sturdy washers at ‘either end’ – it’s better explained in the photo below).

-Firstly, remove the rear wheel/disc caliper/cranks/rear mech/pull mech cable out of swingarm.

-Then undo all the m4 bolts on the linkage, and remove the linkage plates (all the black bits of metal!). These have the smaller bearings on them).

-Using a 10mm allen key, remove the big silver caps on the swingarm pivot.

-The swingarm ‘pivot’ was a right git to get out! I pulled it out using the home made press (so that by tightening the nuts, you are pulling it through the swing arm.) I don’t have pictures of this (as I wiped my phone in the afternoon!), but essentially the ‘order of things on the threaded rod’ went like this:

M8 Nut : Washers : Several stem spacers!(to pull the pivot through into) : swingarm + frame, with the rod passing though : 17mm socket tool (this matches the size of the pivot perfectly) : M8 nut.

As you tighten the first M8 nut, it pulls the rod through, pulling the Pivot with it.

-Once this is through, you have a swingarm with 4 larger bearing in it.

-These bearings are a pain to get out, but by using the puller and a vice as shown in the pics, and a larger socket (21mm i think?) it’s the same principle of pulling them out:

You can see the swingarm resting against the vice, so the bearings have a clear ‘run out’, with the socket the ‘other side’ of the bearings (in the first pic) You can also see how simple the headset press/bearing puller is.

-once the bearings are out on both sides, you can press new ones in:

You can see here the old bearings will be used to press the new ones in (the old ones are on the right/outside)

Here you can see how tightening up the M8 nuts ‘squeezes’ everything together, pressing the bearings in.-That’s the swing arm done.

-In order to press the bearings out on the linkage parts, you have to loosen the 2mm grub screws that hold the bearings in place, then using a vice, 17mm and 21mm socket, you simply sandwich the linkage plate/bearing between the sockets (paying attention to the fact the bearing can only come out one side of the plate – put the 21mm socket on this side) and close the vice. This will press the bearing out ‘into’ the 21mm socket. Use the old bearing to press the new bearing back into the plate, and tighten the grub screw. Do this for all 4 bearings.

-The part that connects the swingarm to the linkage plates is a bit harder to get the bearing out of, so for this I had to use a long (about 8 cm) allen bolt, vice, and 21mm socket again. It’s obvious once you’ve got all the parts in your hand, but essentially you sandwich it all together, as in this technical drawing:

Again, use the old bearing against the new one, in order to press it back together in the vice.

So there you have it – try to avoid hammers, and the bearings need a sloooow, steady pressure to come out (which they will!).

Any questions, fire away…!

DrP

leeroybrownFree MemberPosted 12 years agonice one, thanks for this i will need to change mine soon

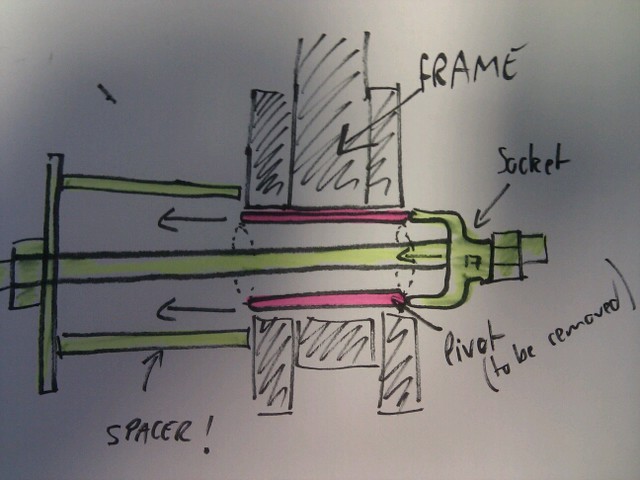

DrPFull MemberPosted 12 years agoHere is another technical (!) drawing of the setup to remove the pivot from the frame…

Tightening up the nuts (on the threaded rod) ‘pulls’ everything together, thus forcing the pivot (in pink on the diagram) out…

DrP

The topic ‘Replacing the bearings on a Meta 5 – a quick "how to"…’ is closed to new replies.