- This topic has 49 replies, 24 voices, and was last updated 13 years ago by Macavity.

-

Designing your own bike frame

-

robbo1234bikingFull MemberPosted 13 years ago

As an automotive engineer I am fairly confident that I have the ability to design my own bike. I wouldnt be looking to anything radical but just being able to ride something that I had designed rather than someone else.

I have access to CAD, FEA etc so pretty sure that I can design something that is practical and strong enough – if I produced drawings of what I wanted, what sort of cost am I looking at from a frame builder. Its only going to be a one off so UK based and I would think steel rather than ally or ti…

Over to you the experts now!

NicknoxxFree MemberPosted 13 years agoAssuming you use standard tubes and they’re not bent or hydroformed you’re probbly looking at about £750 Justin Burls can do you a titanium one for £1000 Lynskey will charge a bit more.

oldgitFree MemberPosted 13 years agoDepends what material you’ll want to use. That’s going to be a tough shout coming up with a better design than the big boys.

I’m building a steel bike, but I’ll be using lug sets. It’s not a new design or anything radical, just cues from the things I like i.e 1″ steel lugged frame, track ends, canti bosses, cross specific stays and straight steel fork.

Looking to have the forks and stays half chromed.

Should look pretty.damo2576Free MemberPosted 13 years agoNo not loughborough – why do you ask?

I studied Automotive Engineering at Loughborough. Long time ago!

robbo1234bikingFull MemberPosted 13 years agoAh right – no Coventry for me. Are you still in the auto industry?

woodsmanFree MemberPosted 13 years agoI’ve just done exactly that – pm me if you want to ask anything.

I’m in the motor trade too!

cynic-alFree MemberPosted 13 years agoAs above do you think you’ll do better than pros? Will you want to spec your own tubes?

ahwilesFree MemberPosted 13 years agoi’ve had a couple of full-bounce frames built.

i needed to make some jigs and things, get some laser cutting done, and some widgets, etc.

1 frame? – about 2grand.

that will include making a couple of jigs, and buying tubing in minimum orders,.

the second frame will cost about £400 – mostly in welding time.

i bought / used T45 tubing (plain gauge reynolds 853) which costs £20 / metre, and comes in 5m lengths – you can buy 1m lengths, but it’s more like £30/m.

i’ve got loads left over if you’re interested…

damo2576Free MemberPosted 13 years agoAh right – no Coventry for me. Are you still in the auto industry?

I went to work in the City!

robbo1234bikingFull MemberPosted 13 years agoNot saying that I can do it better than the pro’s but why do people do their own DIY etc etc – its about creating something that you have worked on from the ground up

ahwilesFree MemberPosted 13 years agoand of course you’ll learn heaps about bike design, simply because you’ll have to.

it’s a totally worthwhile experience!

NicknoxxFree MemberPosted 13 years agoI did it and it’s a very satisfying process. See the results here if you missed it.

http://www.singletrackworld.com/forum/topic/my-new-bike-warning-uber-niche-content

Yo have discovered Bikecad haven’t you?

http://www.bikeforest.com/CAD/bcad.phprobbo1234bikingFull MemberPosted 13 years agoNick – yeh I saw our thread inspired to get going with it. Going to have to do it during lunchtimes but no need to rush it!

Edric64Free MemberPosted 13 years agohttp://www.littlefishbicycles.com/

Check out this site for home building tips

cynic-alFree MemberPosted 13 years agoFair enough op. I designed my own in terms of geometry and specing tubing.

Rides well and was good fun. Didn’t do any FEA. The chainstay broke. 🙁

dxbFree MemberPosted 13 years agoI’d seen this link before, and thought it sounded great.

Don’t know anyone who’s done it though…http://www.daveyatescycles.co.uk/custom_bike_frames-About_The_Course-44.php

pushbikeriderFree MemberPosted 13 years agoYou could always go titanium, although it would be Chinese 🙂

Circa £500 – £700 depending on options, more details over here: Spanner Bikes

richmarsFull MemberPosted 13 years agoYou can always do it in carbon, then you don’t have to mess around with all that welding stuff. Lots of stuff on the net, plus I’ve done a few.

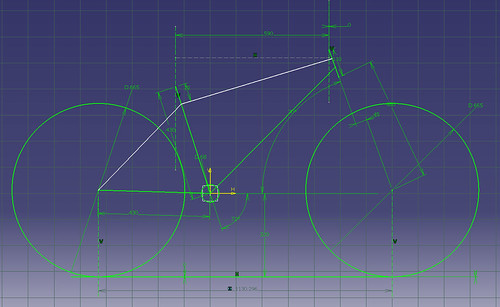

robbo1234bikingFull MemberPosted 13 years ago

Initial geometry by robbo1234biking, on FlickrWell started having a look at geometry and already getting much more complicated than I thought. Based around my 456 (which is a 16″) but I want a slightly less steep head tube, and a bit longer chain stays. I also wanted a longer cockpit as I can find the 16 a bit too cramped. So this is the initial layout. Not sure if the top tube is coming out too steep though and I need to measure the saddle to bottom bracket length on my current bike to find out where the saddle would end up based on a straight seatpost…

james-oFree MemberPosted 13 years ago70 degrees at 509 fork length is pretty steep, almost 29er angles, i doubt the 456 was that angle? it’s a good couple of degrees steeper than i’d go for if using a 120-140mm fork and want something slack-ish. static and sagged head angles as well as the way brands express them (ie with what fork fitted or how much sag?) is a bit of a minefield, it would be good to check this.

The bb is very low too – 10mm lower than a road bike, w/o sag. 300-320mm is more common.Bikecad’s a great thing for playing around with layouts before committing to Acad, there’s a lock feature that allows fork length effect to be accounted for. either that or use a trig calc to see how an angle changes with fork travel/length.

ahwilesFree MemberPosted 13 years agothatser very low B-B.

262mm?!

you can do that if you want, but i wouldn’t recommend it…

(and are you sure that a reach of 367mm is more than your ‘cramped’ 16″ 456?)

tip: start from ground level – start with a BB about 300mm off the floor and go from there – raise it a bit or lower it a bit depending on your tastes.

other than that, it looks to me like you’re thinking about things and drawing them in the right way, it’s just the actual numbers are little ‘specialist’.

(you’re obviously not tall, longer chainstays than a 456 will make it harder to un-weight the front wheel)

james-oFree MemberPosted 13 years agoBB height and angles all depend on your fork length though – 300mm @ 509mm fork length is still a really low BB once that fork’s well compressed. it can be better to work around a ‘sag plus a bit’ measurement so that you know how the bike is when it’s being ridden, the static dims are what they are, they don’t really matter beyond being used as comparisons with other bikes.

in this case the designer’s better to base it all on static dims as it’s easier if working off another bike that he can measure, but you need to look at what happens at around half compression / get an idea of how the measurements change as the frame pivots around the rear axle under fork compression.robbo1234bikingFull MemberPosted 13 years agoThe 509 is based on a figure I found on the internet – need to look at my actual forks when I get home tonight. I have raised the bottom bracket height a bit and things are starting to look a little better. The cockpit figure was wrong have increased it to 590 horizontally (a 16″ 456 is 584mm an 18 is 597 so ill prob go more towards the 18″ but with a lower standover height as I have short legs!)

Attempt 2 by robbo1234biking, on FlickrStill need to play around with the fork length some more.

James-o – I have set up on the CAD so that I can play around with the fork length and see what the effective angle would be

Disco808Free MemberPosted 13 years agoThat looks like a Catia V5 screen grab if not mistaken?

Am also an Automotive design engineer that runs a mountain biking business in the alps, its not a bad life designing racing cars for half the year and riding my bike for the other.

Guided a guy last summer who had built his own full sus, he had the pivot points for the rear suspension on adjustable plates so that he could trial different rear end geometry through the week, something that’s certainly worth thinking about.

Have been thinking of doing a bike myself but check out empire cycles run by a couple of ex Jaguar employees who have taken a very radical approach to bike design!

robbo1234bikingFull MemberPosted 13 years agoThe empire concept is really nice. The tooling for a sand casting might be a bit expensive though for a one of frame!

And yes it is V5

supersessions9-2Free MemberPosted 13 years agoCast frame? a bit like Kirk did in magnesium back in the day……

rootes1Full MemberPosted 13 years agoif you are looking for frame tubes, drop oust etc in alu, steel and ti…

this is a good place to get some from:

kimbersFull MemberPosted 13 years agowell belt drive/gearbox compatible would be nice, so no flex in the rear

internal cable routing

new syntace compatible rear end

seat tube at least 30.9 to accomodate all flavours of uppy downy post (cable stops for remote too)james-oFree MemberPosted 13 years agoah.. didn’t look like any program i’d seen so i wasn’t sure if you were looking at fork lengths. looks like you’re on the right track anyway )

robbo1234bikingFull MemberPosted 13 years agoWhat sort of wheelbase should I be looking at? Obviously shorter is going to make it a more agile frame whereas longer will make it more stable

james-oFree MemberPosted 13 years agoi’d get the chainstay, effective top tube and head / seat angles sorted, then the wheelbase is what it is. if you’re going for a 430-435 CS, then a front-centre of 680mm + is fine – long chainstays seem to be better balance with a long FC i think. it won’t be a short WB for the reach / frame size but it can still be agile if your weight is in the right position. if you wanted a long CS for better climbing, you could just have 420-425mm stays and a steeper seat angle, lower BB, a lower HT even, as these will all have a similar effect.

RetrodirectFree MemberPosted 13 years agoDesigned one, but built myself:

many framebuilders will want you to work WITH them, letting them pore over what you want and modify it rather than just build any old design someone produces. Quality control, no framebuilder wants to have their name on a dud which doesn’t ride or fit well – because the customer designed it. Not saying that this is the case, but you might get a few no’s before you find someone to build it.

BikeCad is great for messing about with design, i did that then transferred it to a proper cad program afterwards.

Figure out your contact points, bars, saddle, cranks from the fit on your current bike, then decide how you want to change the handling. The front end geo has the biggest effect on how a bike will ride, then bb height … 320mm is really really high unless you’re running the longest of forks.

RetrodirectFree MemberPosted 13 years agoas for chainstay length, how heavy are you (and is that weight upper body or lower)? can you manual and do you? wheels on the ground rider or do you try to pop off every lip you can find?

robbo1234bikingFull MemberPosted 13 years agoCheers for the info. Just measure a few bits of the current set up so will transfer that into the model and see what it looks like. Need to work out how far back I want the saddle which then affects the seat tube angle. Do pop of lips but nothing major – no manualing – never quite mastered it but will keep trying! Will drop the BB height a little as well as I am looking at 130mm forks

The topic ‘Designing your own bike frame’ is closed to new replies.