Home › Forums › Chat Forum › Tell me about small lathes.

- This topic has 18 replies, 11 voices, and was last updated 9 years ago by integerspin.

-

Tell me about small lathes.

-

Nipper99Free MemberPosted 9 years ago

Always wanted something like an Emco Unimat for just tinkering about – does anyone have one or is there anything else I should look at.

bencooperFree MemberPosted 9 years agoHow small? I’ve got four lathes, from a Sherline modelmaking lathe up to a 4.5″ x 30″ Denham. Making stuff from plastic, aluminium or steel?

The Sherlines are great as long as you can work within their size range – powerful, loads of accessories available, it’s still my go-to lathe for lots of jobs.

Nipper99Free MemberPosted 9 years agoLike the Unimat which is a little smaller than your Sherline. Steel and ally mostly.

bencooperFree MemberPosted 9 years agoI’ve never tried a Unimat – for me, the important thing is I can get carbide tooling for it, and it’s rigid enough. Sherline did a negative rake toolholder which is fantastic, but they discontinued it. For steel, carbide cutters are wonderful.

greyFull MemberPosted 9 years agoI have a Emco Compact 8, great little lathe. I use it mostly for making bits for airguns.

I would like something a bit bigger now though Compact 8NorthwindFull MemberPosted 9 years agoI have an ancient Unimat SL1000, it’s been a wee bit love/hate- the rails are pretty flexy when working in the middle which can be annoying, and parts/kit for it isn’t cheap- getting a decent vice to fit it was pretty pricey, I broke 2 genuine emco ones frinstance as they’re basically toys. Oh and it’s really pretty limited in the size of work it can do, not much clearance between chuck and rails.

But it is very small, and surprisingly capable, and wasn’t expensive to buy even with a bunch of tools and the mill convertor (milling with it isn’t very good but still, better than nothing). I don’t really have space for anything bigger, if I did and I had the money I’d love to upgrade but it does a job and I don’t know what would do it better with my space limitations

TBH I’m a horrible machinist and probably a halfway decent operator would get more out of it.

finishthatFree MemberPosted 9 years agoI have a Unimat 3 – this size of lathe is the smallest before you get to watchmakers lathes.

It works well for tiny things – has high speeds suitable for less than 10mm work. It is really size limited so what you want to do matters a lot.

It is really about what you want to tinker about with, and money – they can be expensive – with lathes the tooling/chucks can be expensive.

I think mine cost me about £100 with the milling attachment but that was 15 years ago – these days – probably £300 .robdobFree MemberPosted 9 years agoI would love a lathe but I have no idea how to use one, is it easy to pick up how to?

finishthatFree MemberPosted 9 years agolathes.co.uk for all info about lathes.

not easy to just pickup the skills + lathes do need some discipline to

work with safely.Nice watchmakers lathe with some tooling – it is a specialist zone a craft.

NorthwindFull MemberPosted 9 years ago@robdob- the basics are fairly straightforward but it needs a bit of reading/learning. And safety’s really key, you can do a lot of damage in a hurry with a lathe. I could do useful things with mine after a few hours reading, pissing about and destroying things. But I know my limits and they are limitey. I guess it depends what you want to do.

robdobFree MemberPosted 9 years agoIt’d be nice to start making some custom spacers and washers, I’m always finding I need to do something that would look great if I had a special bit of metal or something that I could make on a lathe. Just read about some safety stuff, I can see it’s very important and I’d probably have a checklist up around the machine I could work to – yes I am that organised!

Anyway, what sort of stuff have people made on these small lathes? Any examples people can share of bike specific stuff?

porter_jamieFull MemberPosted 9 years ago

made this earlier on the Harrison which is like a Colchester. It’s for checking balance of mc flywheels after I lighten then (on the lathe ) I made a dummy Crank to hold the flywheel too (on the lathe)

Having always (literally since I can remember ) having had access to a lathe it would be as strange as not having a socket set to not have one. Find someone competent and get some pointers. Safety is absolutely key. There’s a few good books about ill post up a link laternachFree MemberPosted 9 years agoRobdob: A chuck key with a spring in the end can go a fair way toward safety, as well as no long sleeves or ties, etc. I’d do as Northwind did, or find someone to do some kind of introductory training with you.

I had a few hours training in a hackspace by making an aluminium plumb-bob under instruction, and can now figure out ways to do most cuts I want, but there are certain ones I can’t do very well yet.

If you’re looking for something bigger and don’t care about metric thread, Myford Super 7’s are lovely machines.

porter_jamieFull MemberPosted 9 years agoMachine Shop Trade Secrets: A Guide to Manufacturing Machine Shop Practices https://www.amazon.co.uk/dp/0831134771/ref=cm_sw_r_awd_-l-TvbTCZXTQ8

Not cheap but genuinely absolutely worth every penny. So much valuable info this will save you hours and hours

rc200f8Free MemberPosted 9 years agoI bought an old myford ml7 a few years ago, a great little lathe. It’s an imperial machine but you can cut metric threads with one or two additional change gears, you can also carry out some basic milling of small items with the vertical slide. I find it pretty versatile without taking up too much room.

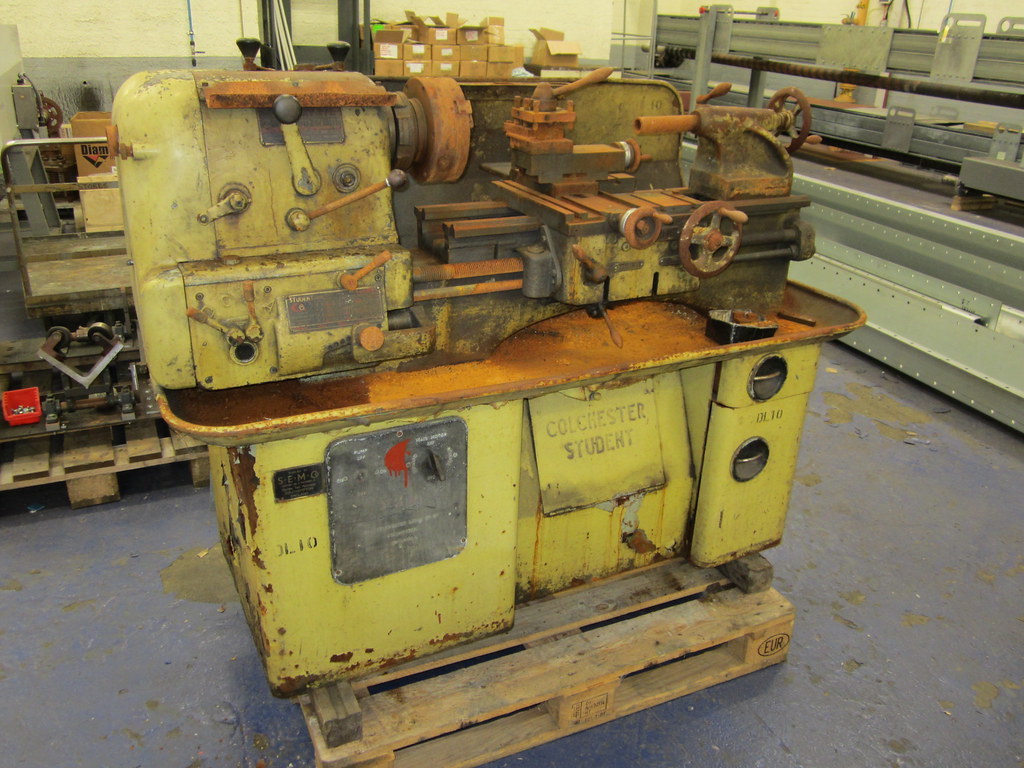

fruitbatFull MemberPosted 9 years agoI’m currently renovating this 1954 Colchester Student

It’s not that small really. I got it from work for free (had to pay for transport though!). When you see what people ask for bits on eBay I figured I had nothing to lose.

integerspinFree MemberPosted 9 years agoSafety, just don’t do anything stupid.

As for learning to turn, just get a lathe and go for it. I got my first

lathe and within a few hours I had made some threaded parts for my chop.

Here’s my first lathe:

It looked tidier in the scrap yard I got it from;-)

The topic ‘Tell me about small lathes.’ is closed to new replies.