They are remarkably small and portable.

Thought I'd start this thread to solicit mockery from people with proper MIG machines and as a support group for anyone else who'd succumbed to the temptation of the middle isle this week

Look the picture even shows it doing it al itself, how hard can this be!

Next stop, Toolstation for some gauntlets and a proper mask. Lidl did have some but I figured between my technique and flux core wire that the amount of splatter was going to make a mask with replaceable glass important!

I did like the LIDL mask, for the price, iirc it had a large viewing are, one had an LED to see better. BUT you have a plastic screen over the glass so you dont destroy the element, and theres probably spares in the box, and easy to cut others to size

I didnt know you can get inverter MIGs these days, if thats what it is.

Considering buying one myself but >150A and dont want gasless or flux core

Yea, I'm not under any illusions that it'll do a great job, and will be out of it's depth on anything heavy.

But I've had a so many times of times in the past year working on cars / bikes / pizza ovens / gates where I've thought that if I could just tac this together it would be so much easier than trying to bracket/sleeve/clamp/bolt or whatever it is I'm doing instead.

Watched a few youtube videos of people managing to do car bodywork with it set to minimum, so if I can get in anyway half decent with it I might attempt a rusty mx5 or something😂

whatever you get youll need lots of practice anyway and once youve got the technique you can get something bigger if need be. But it will be frustrating to begin with

I think I'll purchase a handheld drill style welder when they eventually appear in the middle of Lidl.

I bought a piller drill from Lidl and it is pretty good.

whatever you get youll need lots of practice anyway

it’s great practising on scrap metal on a bench, but then you go to work underneath a car and it goes back to square 1

I opened this thread thinking god no, not another far right Dutch politician

whatever you get youll need lots of practice anyway

it’s great practising on scrap metal on a bench, but then you go to work underneath a car and it goes back to square 1

a lot of which is getting a good earth, and cleaning the metal to weld on. Consider that old metal will be thinner and rusty, you want no gaps, and welding on your back, sideways, vertical, etc without room to move your head and arms makes a massive difference to your proficiency

Hmm I haven’t bought the LIDL Welder but I do have a lot of welding experience and I own a.n.other cheap MIG Welder.

My biggest problem is the electronics on the welder - my welder seems to work really well for the first 5 minutes of welding. After that the arc becomes unstable and difficult to weld with. If I leave it to cool off between 5 minute welding sessions it’s fine :o)

Bear that in mind with yours and have fun ;o)

Does it have the option to connect a gas bottle to it and use 'normal' MIG wire? If so it could be a good buy. I'm afraid 'gasless' MIG is a bit crap, however good your technique!

The pain of Mig spatter fizzing in your ear..........Mig welding only exists to highten the Zen experience of Tig welding.

@thisisnotaspoon don't you own an MG Midget? I thought a MIG welder came in the toolkit for them with the sparkplug spanner ;-). (Speaking as a former Midget daily driver.)

As others have said, practice, practice, practice, and then you'll start working on the car and it'll all go out the window.

That said, I "invested" in what I thought was a good SIP machine, never got on with it and generally hated the whole thing. A second hand TIG machine was actually much better for what I was trying to do (Mostly fixing 70's MGs). Then I found that the supposedly good SIP machines were widely hated by just about everyone as the wire feed is inconsistent and can't be realistically made to work nicely. I've now got a Machine Mart cheapie and it's 10x better than the supposedly semi pro machine I thought I was better off with. One doesn't always get what you pay for.

I looked at getting the parkside one and even went so far as to watch some vids.

Did find one of a professional welder using the parkside one to construct a fence in heavy steel bar.

He rated it as acceptable.

Maybe not if youre into welding or its structural or critical, but just for fixing the lawnmower or garden gate, it would good to have around.

Or use it as a latest toy and play with it till the latest toy buzz wears off/you burn yourself/set fire to the shed.

don't you own an MG Midget?

I do, I had to drive back to the office to pick up the welder as I'd ridden in.

Having the welder in the car felt like a circle of life moment 😂.

I looked at getting the parkside one and even went so far as to watch some vids.

Yea, I found these two. No idea how competent they are as welders but in terms of use in do need to modify a bike trailer and do have the MG!

Also found another video where the guy showed a more general overview of the process with one and how to get a decent weld, and also how to get something that looks aesthetically at least nearer a nice fillet of stacked 5p's, but then showed it gave much poorer penetration than the first technique.

Can’t see how it can be worse than my crappy Arc welder from Makro 20 years ago.

With care and patience it can weld old german car panels.

It absolutely would just blow holes in a modern car panels.

I learnt Arc and oxyacetylene at college 35 years ago. Never tried MIG or TIG, I’ve heard they’re much easier, so tempted by the Lidl welder myself.

😂

Yep, I need to take my screwfix grinder apart and fix that too, think the switch or a connection is loose as it's become "shake to start" which is sub optimal for something that could remove limbs 😂

i love a welder - wonder if my lidl has one in? scenic route home for me tonight!

most old car bodywork needs to be done with as low a setting as possible anyway so low power is good. Alot of teh larger machines dont go low enough to not just burn through everythng.

I'm sure there is a lesson here somewhere. As my dad used to say, buy cheap, buy twice.

under appreciated comment from kormoran.

I'm sure there is a lesson here somewhere.

Ohhh what is it?

As my dad used to say, buy cheap, buy twice.

Hate to break it to you, opinions are the cheapest commodities on earth.

Well I didn't expect to buy a welder at lunchtime. But that's what I've done.

I have a job for it that I've been putting off though 👍

I believe with Mig, if you don't use it for a while you'll need to bin any remaining wire and buy a new spool. It rusts ever so slightly and stops feeding reliably.

It's this sort of thing that makes having a welder in the shed for the 'I'll just tackle that' moment, not so handy as you might hope.

NeilNeville - seems to be OK with me? i suppose it depends on how long you leave it. I own a t2 baywindow (muchos rust!) so i leave it about 6 months between uses (winter!). I may howvere begin to wrap the spool in clingfilm as it kinda makes sense it would degrade. my garage isnt that damp so maybe i`ve been lucky.

better to keep big spools indoors if not being used, but i guess it depends how good the feeder spools/motor are

I know that the chinese may make several different qualities of the same item, so you may choose to suit your needs, so a bargain may be not a bargain, if youre thinkin you have a lifes' supply of brake pads, and some money left over.

Lidl Welders... far superior to the big hairy types when you need to get into a tight space.

VanHalen, maybe some welders or wires are better? Iirc, I read it on a similar thread here and it made sense. 30 years ago I learnt to drive in a ratty old mk1 fiesta and my brother and I were forever chasing rust so we bought a cheap mig, Clarke iirc. Remember after a while the wire feed became trouble, the wire seemed to jam. Very frustrating and we didn't know why. Now I do.

I hadn't used the welder in 25 years so when mum moved and we cleared the garage i gave it away to a neighbour, but told him, if you user it, buy a fresh spool!

If i still had it i would take the spool out to store it inside between uses.

Yea, I read similar, take the spool out (careful not to let it unwind) and store in a sealed tupperware.

The spools are only £2.99 though so it's not really a big deal to just buy a fresh one if there's a big job to do. Could be annoying if it was just to tack something quickly.

I've no real inkling of how far 0.45kg of wire goes though? Based on a 4mm triangular fillet that would be almost 700m, I'm guessing by the time the gas has vaporized and splattered a lot of metal with it, that it's a lot less!

The wire will go a long way.

Hate to break it to you, opinions are the cheapest commodities on earth.

Yeah, like assholes, everybody’s got one! 🙃

Head down your local motorbike garage and ask for scrap from their bin. Car brake discs are good to practice on. Car panels are not the place to start as you will just blow holes in the metal.

Your welding will be crap and weak to begin with but that shouldn't stop you enjoying it and making stuff. Go for it.

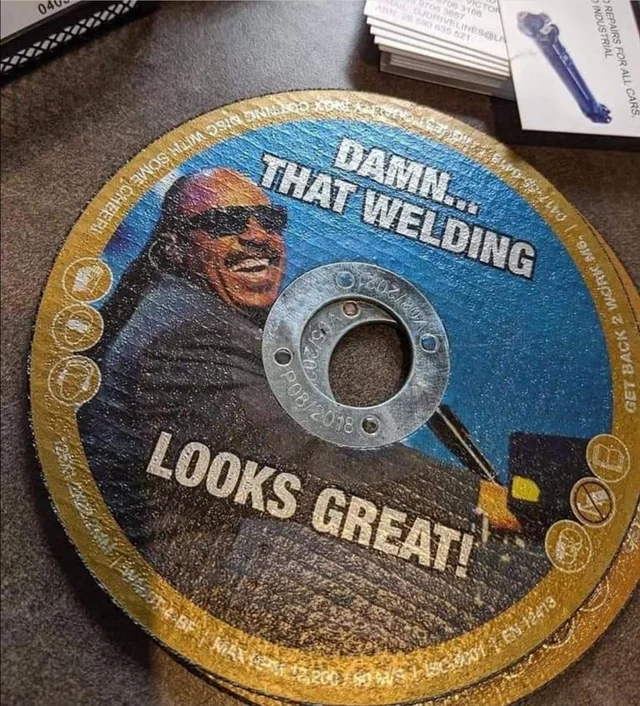

https://photos.app.goo.gl/WdH1eijSsb2BgDcP7

Bit of an update, signed up for a C&G Level 1 course at Langley College, no doubt it will metaphorically fall apart when I try to apply it to the Lidl machine 😂

I did look at the cost of the college machines and probably had the same expression the average person has to my bikes "you could buy a car for that!"  Lap joint on a piece of scrap before doing the proper test coupon, got a fist bump from the instructor which I'm taking as the welding equivalent of the Hollywood handshake 😂

Lap joint on a piece of scrap before doing the proper test coupon, got a fist bump from the instructor which I'm taking as the welding equivalent of the Hollywood handshake 😂

That looks great to my untrained eye but what I’d really like to know is how you’ve got on with the Lidl welder? For hypothetical example, if you’d welded a frame to make a bench would you be happy to plonk yourself down on the bench or always lower yourself carefully?

That looks great to my untrained eye but what I’d really like to know is how you’ve got on with the Lidl welder? For hypothetical example, if you’d welded a frame to make a bench would you be happy to plonk yourself down on the bench or always lower yourself carefully?

I've not actually used it in anger yet 😂 every free day seems to be raining at the moment.

Speaking with the instructor he said cheap welders are harder to master as you don't have direct controls (there aren't dials labelled amps, volts, wire feed, etc) so you have to do things by proxy, there's just one dial that adjusts wire feed rate and current together.

e.g. on the fancy machines if it's too hot I can just turn the voltage down. On the Lidl you can either

- let more wire stick out the gun, so it acts as a resistor.

- use thicker wire, the pool forms faster so you move on quicker.

Also, in the UK/Europe most people are taught to 'push' weld, where you angle the torch back 15deg so the arc is blowing forwards over the molten puddle, this heats up the metal ahead of the weld and gives more more penetration / fusion. In the USA they often work the other way, dragging the weld. Which in theory is worse, the heat of the arc has to go through the molten puddle to melt the metal below it, in reality both should give you a weld that's at least stronger than the parent metal. Flux core must be dragged though because you want the flux to be blown over the molten metal to protect it, not deposited on the cleaned surface ahead of the weld.

It will also look different, the basic technique is to zig-zag back and forth over the joint so both pieces get heated by the arc evenly, this works for flux core or MIG. To get the nice fish scales like that pic you alter that slightly and do "cursive e's", so rather than a squared off zig-zag, it's up, back a fraction, down, forwards, repeat. That's what deposits the nice scales over the top of the last one as it cools, it's not a series of blobs, it's a continuous spiral but squashed flat. With flux core you don't go back and disturb the flux (which is now cooling and becoming slag), you always have to be dragging it forwards, so it doesn't look as pretty.

Most of the learning is recognising faults in the weld, Level 1 (30 hours) is basically superficial visual checks, which for the fancy MIG machines and thick steel is mostly undercutting (too hot, melting away the parent metal quicker than the wire fills it, so you get a hollow at the edges), or lack of fusion (too cold, the edges of the bead don't stick so appear convex rather than concave).

So to answer the question in a roundabout way, at the absolute peak of the Dunning-Kruger trap, I'd happily build a bench and sit on it, as long as I could do a decent job of setting up the machine. The first things I need to do are a welding table (Like in that pic, a big grate that you attach the earth clamp too rather than have to connect it directly), then I want to make a better bike trailer as both my current ones are flawed for what I need them for.

Small cheapo welder is a tool every householder should own.

Little jobs, like for example fixing a garden gate. Easy to do, not a critical thing, but probably pay for the machine itself on that first job, over the cost of calling out someone to do it for you.

interesting , with flux core do you have to deslag it after/before another run?

You put more heat into it going forward.

I want to make a better bike trailer as both my current ones are flawed for what I need them for.

I'm keen to see how that goes before I buy more Parkside shed clutter 😀

interesting , with flux core do you have to deslag it after/before another run?

Yes, also check the wire is suitable for multiple passes, not all are. And to be fair I doubt many people are buying cheap welder's for things that require multiple passes.

You put more heat into it going forward.

Yes, but you'd just be blowing slag where you want to weld.

interesting , with flux core do you have to deslag it after/before another run?

Yes, also check the wire is suitable for multiple passes, not all are. And to be fair I doubt many people are buying cheap welder's for things that require multiple passes.

You put more heat into it going forward.

Yes, but you'd just be blowing slag where you want to weld.

Hmmmmm

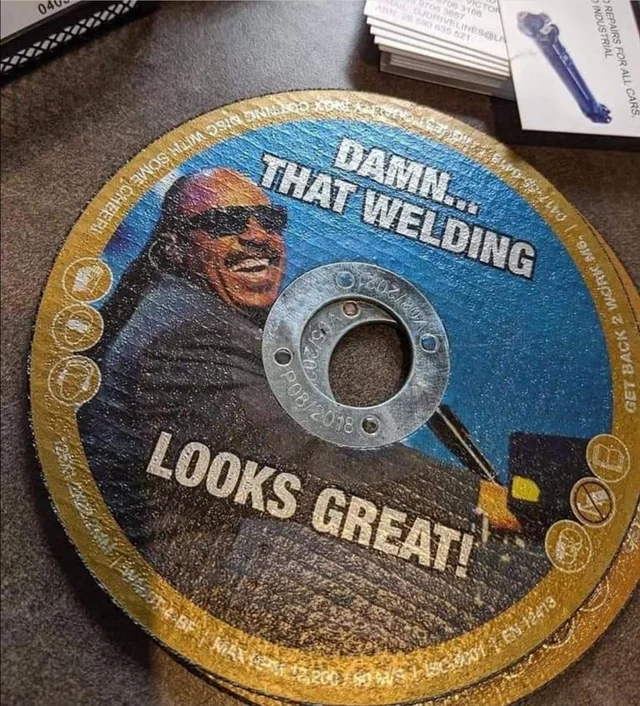

Vikki works in HR so I'm calling this piece of art Diversity and Inclusion 😂

I'm not entirely sure where it's going wrong but I suspect that the wire speed Vs current is too low, and given that there is no control on the welder that means thicker wire is needed. If I turn the dial up to 3.0 then it will actually blow a hole through this 1/8 steel quicker than it fills the weld. But this on 1.5 I think means the travel speed is too low so there's too much flux/slag?

So in answer to the question can a complete beginner weld with a cheap welder, yes, I'd happily glue bits of metal together with it. Can I do it neatly, no not yet anyway. Would I trust those welds on anything even slightly critical, hell no!

I've got a pile of old bike frames to practice on some thinner steel. I actually suspect that may be better.

Hmm, welding Vikki not going well? Maybe screw or nail instead 😀 (good luck with HR 😀😀 )

I've got a pile of old bike frames to practice on some thinner steel. I actually suspect that may be better

Thicker metal and new metal is easier to weld as you can whack the settings up and things are consistent.

Old thin rusty metal is a right bugger to weld up as it's all different thickness. I have a classic vehicle which is ALL thin rusty metal - the chassis is much easier to weld than the bodywork as it's much much thicker.

Yea, I still suspect that thinner metal will work better with lower settings, my uneducated guess is that it's in some way too hot. I've got a few spools of different wire thickness so can try both.

I wouldn't have used a serif font.

I wouldn't have used a serif font.

I think the splatter counts.