I'll soon be the proud owner of a garage at the top of the garden. At the moment it's got a fairly flimsy garden gate type door fitted to it and I want to beef it up.

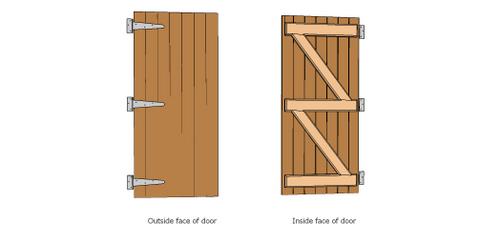

Could I build a door like this:

[img]  [/img]

[/img]

out of wood like this

[url= http://www.wickes.co.uk/Wickes-Treated-Kiln-Dried-C16-Regularised-45x145x3600mm-Single/p/190169 ]http://www.wickes.co.uk/Wickes-Treated-Kiln-Dried-C16-Regularised-45x145x3600mm-Single/p/190169[/url]

painted/varnished and held together with screws and coach bolts?

The doorway is only small (700x1700mm) so any premade doors would need a load of cutting to fit.

Has anyone else done anything similar?

No reason why you couldn't (IMO, etc.)

I built something similar a few years back. Pics are on that 'wothca made recently' thread.

I used some sash clamps to hold it together whilst the glue dried. Expensive if you don't own them.

[URL= http://i1205.photobucket.com/albums/bb427/Hans45/97215b09-14fa-4113-8e15-09a498baffcf_zps5f34f4a4.jp g" target="_blank"> http://i1205.photobucket.com/albums/bb427/Hans45/97215b09-14fa-4113-8e15-09a498baffcf_zps5f34f4a4.jp g"/> [/IMG][/URL]

http://i1205.photobucket.com/albums/bb427/Hans45/97215b09-14fa-4113-8e15-09a498baffcf_zps5f34f4a4.jp g"/> [/IMG][/URL]

[URL= http://i1205.photobucket.com/albums/bb427/Hans45/DSCF6855_zps3c383dae.jp g" target="_blank"> http://i1205.photobucket.com/albums/bb427/Hans45/DSCF6855_zps3c383dae.jp g"/> [/IMG][/URL]

http://i1205.photobucket.com/albums/bb427/Hans45/DSCF6855_zps3c383dae.jp g"/> [/IMG][/URL]

[URL= http://i1205.photobucket.com/albums/bb427/Hans45/DSCF7021_zps27603072.jp g" target="_blank"> http://i1205.photobucket.com/albums/bb427/Hans45/DSCF7021_zps27603072.jp g"/> [/IMG][/URL]

http://i1205.photobucket.com/albums/bb427/Hans45/DSCF7021_zps27603072.jp g"/> [/IMG][/URL]

It's since had some reinforcing in the inside with the 4x2 and in the hot weather the gaps opened to about 4mm as I didn't run bolts all the way through. You could use a length of threaded bar with some recessed nuts if you wanted to go down that route, which I would if I done it again.

Anyway, I filled the gaps with a flexible filler and it's all good now.

Thanks Teasel, that looks good. Kind of what I'm aiming for, solid wood that's thick enough to fit a proper lock and hinge bolts to.

Crack on I say.

I'd question your choice of timber though, you don't really need the posh c16 stuff, I'd just use the white wood PSE from wickes. You could use the 145x45 if you like, but for me that would be overkill, I'd prob go half as thick, otherwise the door will weigh an absolute ton and need serious hinges.

Very simple, but do it like your original diagram with diagonal batons, not like Teasel's. Use thicker timber for your batons, 3-4 sunk-head nails at each board/baton junction and angle your nails in all directions to avoid them popping apart at the first sign of a rain shower.

When I've made board-and-baton doors, I tend to make them long and then trim them with a rip saw so you get nice straight ends. Don't forget to use a capping profile to protect the end grains at the top...

And as Goldfish says, don't waste money on the highly planed stuff - if anything, rougher-sawn timber takes treatments better.

OP

I used 3/4" tongue and groove flooring to the same design as you have shown.Makes it easier to glue together without the sash clamps.

Thanks all, helpful as ever.

Good point about the weight of the door given the thickness of the wood. I picked up a couple of pieces in Wickes ("wickses"?) over the weekend and it was heavy stuff. My main concern was making sure that I can fit a proper lock to it, external doors seem to be 44mm thick which is why I'd picked that 45mm stuff. If it doesn't need to be the treated wood then that's fine. I just saw "for external use" and thought that'll do.

I've used some treated 4 x 2" for external doors and they have twisted pretty badly over the last few years (top to bottom deflection is ~ 2"). Not sure if the C16 stuff might be a better bet

For reference the door pictured above is 85cm x 173cm and came in at just below 60kg. I used four grade 13 hinges but I assume you want the type of hinge pictured in your image.

make them long and then trim them with a rip saw so you get nice straight ends.

Definitely that.

We have ledged and braced doors in the house - I'd say you're better off having the hinges on the cross braces than the flat face.

Like fasthaggis, I used tongue-and-groove, nail gun and glue. Made long, cut to size. Much easier, lighter, quicker.

I also put my hinges on the inside, otherwise your fancy garage side door is beaten with a screwdriver.

Most sawn timber (treated or untreated 4x2 etc ) from Wickes/builders merchant will be c16 graded timber. Doesn't mean its any less prone to warping. Also the treatment doesn't usually penetrate that far so will still need treating once the door is finished.

Generally tongue and groove will have done most of its drying out so if you pick straight bits to start with then glue and nail them they should be fine. You can then just prime and paint it or stain it with an exterior wood treatment and it'll be fine. Make sure the end grain is well treated both top and bottom to prevent it from soaking in and working along the grain. Belt and braces you can paint the timber before you make the door then give it a final coat once complete.

For a strong door use decking boards, cross pieces screwed to back of boards,but there will be gaps between boards, make oversize and cut to fit opening, thats what we do, we make them, A timber yard will have better quality timber due to higher turnover of stock, use VTG boardng veed touingue and groove its about 12 mm thick not the cheaper internal cladding, treat wih numerous coats of wood presever, bolt through hinges if fitted on front, hinge bolts if side hung.

By clamping and screwing up the boards you may find they expand and will then show unpainted or untreated timber at the v grooves

I made all the doors in my house like this. Pretty easy with basic skills. If you are prepared to take a bit more time and effort you can make them far stronger by adding a notch-type joint to the stiles and diagonals which will help stop them from sagging over time.

adding a notch-type joint to the stiles and diagonals which will help stop them from sagging over time

Every day's a school day n all that. I've been looking at an ancient pair of gates just across the way from me the have just that sort of joint and been wondering for a few years now...

It's dead easy. My brother and I made one for his shed. Having a couple of sash clamps to pull it all together helps. We also used slightly longer brads which we nailed from the front side. The excess which protruded on the rear we clinked over along the grain of the bracing bars. It prevents the door springing apart when it shrinks or swells.

I've used the floorboards ^^ in the past. The other version that's quicker and doesn't need sash cramps is to use an exterior-grade plywood with a weatherproof glue bond

Choose a thickness (add a bit for plank lines-see below) / finish / weight that suits you and have it cut to size

Frame it up to suit the lock and hinges that you want to fit, and you won't need the diagonals (it's one sheet)

You can score plank lines with a circular saw or router if you wanted them to approx 3mm