I'm guessing some people might have already heard of this, new one on me, pretty amazing though!

I liked the zoom in on the "230 volts" sign 30seconds in. Reminds me those scenes in old US car chase where they'd flash to the speedo creeping over 60mph 🙂

We have one here. It really is pretty cool...

Genius!!!

I really like this [url= http://bldgblog.blogspot.com/2011/07/dune-bank-suitcase.html ]solar powered version[/url] that sinters sand to make glass

the video is a bit of slow burn (pardon my pun)

Its pretty old news I have been using 3d printing bureaus for the last 10 years.

Its pretty old news I have been using 3d printing bureaus for the last 10 years.

Yeah - I was at a secondary school last week doing a photoshoot and they had one there for the design & technology students. It cost considerably less than the first colour scanner I bought too.

It is amazing and I love the technology - understandable that folk who haven't seen it before get blown away.

What I find funny is that video, only posted recently, makes it sound like it was invented last week when the technology has been useable and developing for over a decade at least.

Imagine the next step (OK, or 10 steps) where you have one at home and buy the rights to print whatever you want. Need some grips? Pay a royalty to ODI, download the program and print out some Ruffians! Sinter your own mech hanger etc. Cut out all the manufacturing and supply chain - just pay for the design and make anything you want yourself overnight!

It might sound a bit far fetched but it's not been unknown for the machine in our office to make parts for caravans, radio controlled cars, fishing rods etc.

You can build your own for about £800. Saw it in a magazine t'other day.

Can't recall the name of the place - but it comes in wooden kit form.

http://www.makerbot.com/ is the one i saw that was quite cheap.

Like i say though, i know people have heard of this before, first i've seen it though. Not really as if it's well broadcast and until recently it's been pretty cost prohibitive to the average punter, so I'd guess that is the news worthy bit.

I still can't work out how it makes things which can rotate on an axle..

Absolutely - as the price comes down, these could be a revolution! Even just in terms of getting prototyping abilities into the hands of more people.

Charlie - the model is built in layers. Think of it like a backwards bacon slicer!

Binder is being used to stick the powder together where you want the model to be solid. This is applied very accurately with the print head, like a dot of inkjet ink. Where there is no binder, the powder stays as powder. The loose powder supports the next layer, which is then glued where it needs to be. When the model is finished, the powder is just blown out from the cracks, leaving captive parts free to move.

heywayne - Member

You can build your own for about £800. Saw it in a magazine t'other day.Can't recall the name of the place - but it comes in wooden kit form.

google reprap for all the info you need.

It's wonderful stuff but caution should be exercised when considering load bearing or structural items especially loads which contain a shearing motion. I'm not sure gravity-slave idea of a gear hanger is wise for instance. This method of manufacture dose not allow a microstructure like many other methods so strength in limited.

Charlie - the model is built in layers. Think of it like a backwards bacon slicer!

sure, but what supports the wheel as it is being layered?

The loose powder supports the next layer

Each powder layer is a full layer, bonded or not. The powder from the layer below supports the layer above.

home made.

ok, i get it. Ta

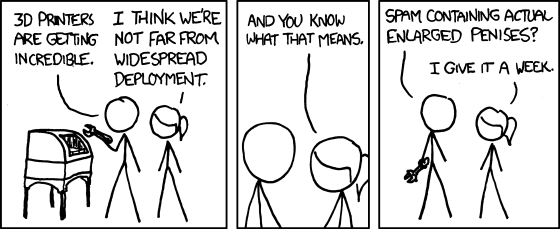

I wonder how many copies of someones willy get made...

😯

We've got a Makerbot here at work.

Its pants.

If I'd spent £800 of my own cash on it I would have been very dissapointed.

SLA, & moreover SLS, has come a long way. Some of the glass filled SLS stuff that companies like Arrk do is amazing. I've had an SLS holding 2 bar of pressure, tapped holes & (after boring) even a working piston in it. The technology is moving so fast these days. It really can be literally CAD screen to working part in 2-days or less.

I'm working on a die-casting at the moment, & we'll get a run of 100 or so gravity castings from a soft-mould made, from a SLA. Fantastic stuff.

I bet you've done your willy though, right?

That is my impression of it, bit like a dot matrix version of this type of printer. Exciting thing is that people are trying to make cheap versions though, which is good. 🙂We've got a Makerbot here at work.

Its pants.

I have just taken delivery of a brand new Z Corp machine. As said above been using 3D printed parts for the past 10 years but the prices of the machines have plummeted over the last couple of years. Over the last 12 months its swung from cheaper for us to use an agency to cheaper owning a machine!

Now what can i go and print for my bike - hmmm

The issue as yet unsolved is that the materials properties (mechanical/thermal and others) are rubbish compared to injection moulded/extruded.

It's not for making stressed production parts (yet!) - it's used for rapid prototyping where you want to see how something will fit/look/work though apparently F1 teams are using it for things like brake ducts, etc which are under relatively low loads.

clubber I know this, but people above were fantasising (as I do) about having a star trek like replicator thing in their lounge..

edit - anyway I've jsut spotted that brick said this above ages ago..

yeah but who knows - might not be so far off (for solid object type things)

...like copies of your willy then?

its pretty far off, I know, I have dog bones of various sls and sla materials tested regularly as they bring out new "ground breaking" compounds.

f1 for ducts etc http://www.windform.it/ used it extensively

have looked at mls for carbon bladder moulded tooling also it works

one day i hope theres a machine just like on the starship enterprise im sure some euro project was picking atoms up and placing them elsewhere to make something different to what they started with but it was mighty slow....

The Arrk rep visited & showed some nice samples. He kept the best till last, nylon filled acetal that was then wrapped with carbon & lacquered. Try as I might there was no way my boss would pay for a carbon wrapped gas valve. 🙁

Should have done his Willy, he'd have gone for that.

to quote Armando Ianucci

"Thats what they said when the piano replaced the harpsichord. They said it'd provide a better, softer sound and have improved online banking facilities. But instead the piano's become an outlet for online gambling and porn."

I had a tour round exeter universities facility a while back. Now that's impressive. Making stuff out of alloys with laser welding, Ultimate aim is to be able to fabricate an aircraft wing...

Yup its very useful. We use it to prove a principal, and even to replicate some 'series' parts which we cannot make at prototype stage. For example current project all the parts that are to be injected will be printed but are ready to be injected if you see what i mean.

useful, and as has been said much faster than traditional processes - aswell as more complicated parts being possible.

It's useful tech but old old old, developed in the 80's commercialised in the 90's.

See Cory Doctorow's book [i]Makers[/i], and Charles Stross' latest book [i]Rule 34[/i]. For those not familiar with the term, Rule 34 states 'if it exists, there is p0rn of it'. It involves fabbers in Edinburg making perfect model replicas of humans for people with, shall we say, rather unpleasant tastes. Cory's blog boingboing.net regularly features stuff from makers using 3D printers.