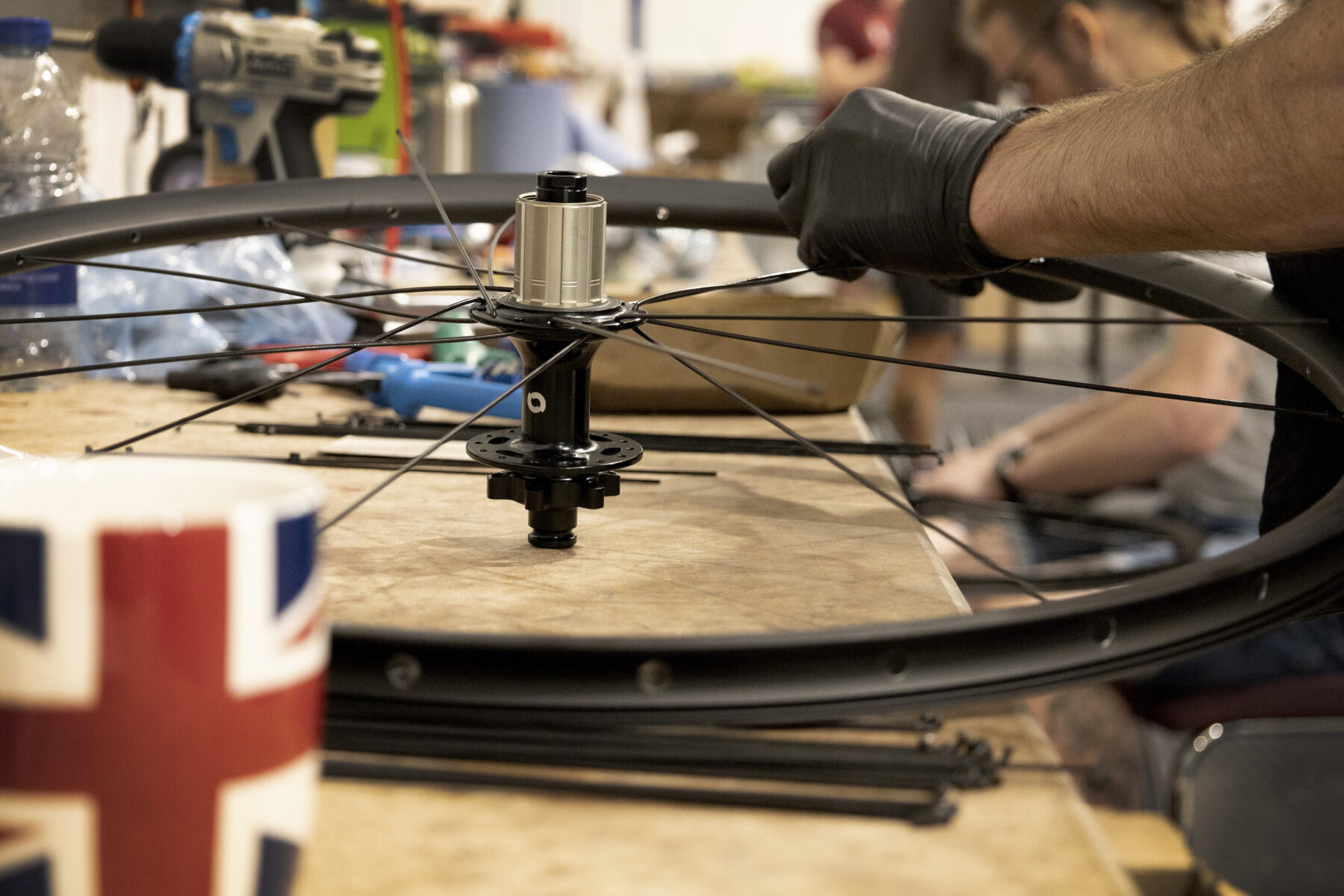

UK brand Sonder – the bike arm of AlpKit – are based on the edge of Peak District and design and make a range of bikes and components to suit everything from mountain, to gravel to road. And they’ve now brought their wheelbuilding in-house…

Press Release

Sonder is Europe’s only B-Corp bike brand. They build every bike to order. And they’re bringing wheel building to the UK – Sonder’s new wheel building machine is based in their Nottingham workshop.

Nobody was making the wheels Sonder wanted. Wide-rim, wide-hub wheels. So, they started developing them themselves. And then they started building them.

Wheels have a huge influence on the character of a bike. When Sonder Product Manager Neil Sutton designs a bike, he conceptualises both the frame and the wheels together. That means the bike rides exactly how he wants it to. And, by building the wheels onsite, Sonder can assure and improve quality and production efficiency. That’s what makes Sonder special.

Sonder’s new wheel-building machine can lace a wheel in just 1-3 minutes! The skilled hands that lace and finish the wheels can put 30 pairs of wheels through the machine in a day.

The wheels are built across two machines: the lacing machine and the truing machine. The lacing machine learns the rim dimensions, spoke count, location of the valve hole and angle of the nipple driver. The result is an evenly tensioned wheel. The truing machine tensions spokes, working towards pre-defined tolerances.

At Alpkit and Sonder, 30% of products are made in the UK. They’re keeping design, development and careers local as well as keeping sea and air freight down. For over a year, Sonder have had a wheel-building machine in the pipeline.

Building wheels in the UK massively reduces shipping volumes. By not shipping wheel boxes around the world – or, more specifically, boxes full of fresh air – Sonder are reducing their impact on the planet.

Join our mailing list to receive Singletrack editorial wisdom directly in your inbox.

Each newsletter is headed up by an exclusive editorial from our team and includes stories and news you don’t want to miss.

You must be logged in to reply to this topic.