One of the complaints many have about carbon fibre is its inability to be recycled. Revel Bikes has teamed up with makers of Fusion-Fiber to bring you recyclable carbon wheels with better environmental credentials.

Fusion-Fiber was developed by an aerospace company as a form of carbon fibre that doesn’t use epoxy. It seems the carbon fibre world is a small one, with a chance meeting on a hillside in Utah eventually leading to this collaboration:

10 years ago, Revel Bikes founder Adam Miller met Joe Stanish (COO of CSS Composites) on the side of the Sardine Peak trail in Ogden, UT. Joe was VP of Operations at ENVE Composites at the time, and Adam had one of his first jobs in the bike industry working for a bike brand down the road. That meeting led to a business mentorship and great friendship. After a few years of meeting up weekly for beers and bike business chats, Joe approached Adam and Revel in early 2019 with this great idea. He and his team at CSS Composites were developing this incredible new composite material that was stronger, lighter, cost effective, and made in America. And they wanted to partner with Revel to release the first bicycle rims made from the Fusion-FiberTM, “But what really got my attention was that the material was 100% recyclable,” said Miller. A strategic partnership was born that has grown to where we are today with the release of Revel Wheels.

“Joe and I worked together at RockShox 22 years years ago, so when we started talking about this, I knew it would be pretty damn rad,” said Revel COO Jeremiah Starkey.

There must be more to it than riding bikes with friends and drinking beer however. This is where the robots come in. Revel’s press release explains the tech:

At a basic level, the crew at CSS removed all epoxy from standard pre-preg carbon and replaced it with advanced polymers – think nylon, but on a whole new level. The raw material is a blend of unidirectional long fiber German and Japanese carbon impregnated with this polymer. In its raw form, it is completely stable, has an unlimited shelf life, doesn’t need to be stored in a refrigerated room like standard epoxy pre-preg carbon, and all of this stable and consistent production.

Not only is the raw material innovative, the manufacturing process is where things get really crazy. The rims are laid-up and cross-plied robotically, leaving no space for human error or inconsistencies. The rims are then flash welded together, with an exponentially faster cure time than current rim technology. Cure times go from around 45 minutes for a standard thermoset carbon rim to 20 seconds with this system, in a completely controlled environment so every rim comes out the same, every time. When the rim pops out of the mold, there is no epoxy resin to be scraped or sanded and it needs no clear coating. These two steps expose most harmful chemicals to the worker and the environment.

With no epoxy or coating, the material can apparently be recycled – separation of different materials being a key barrier to the recycling of many materials. Revel says:

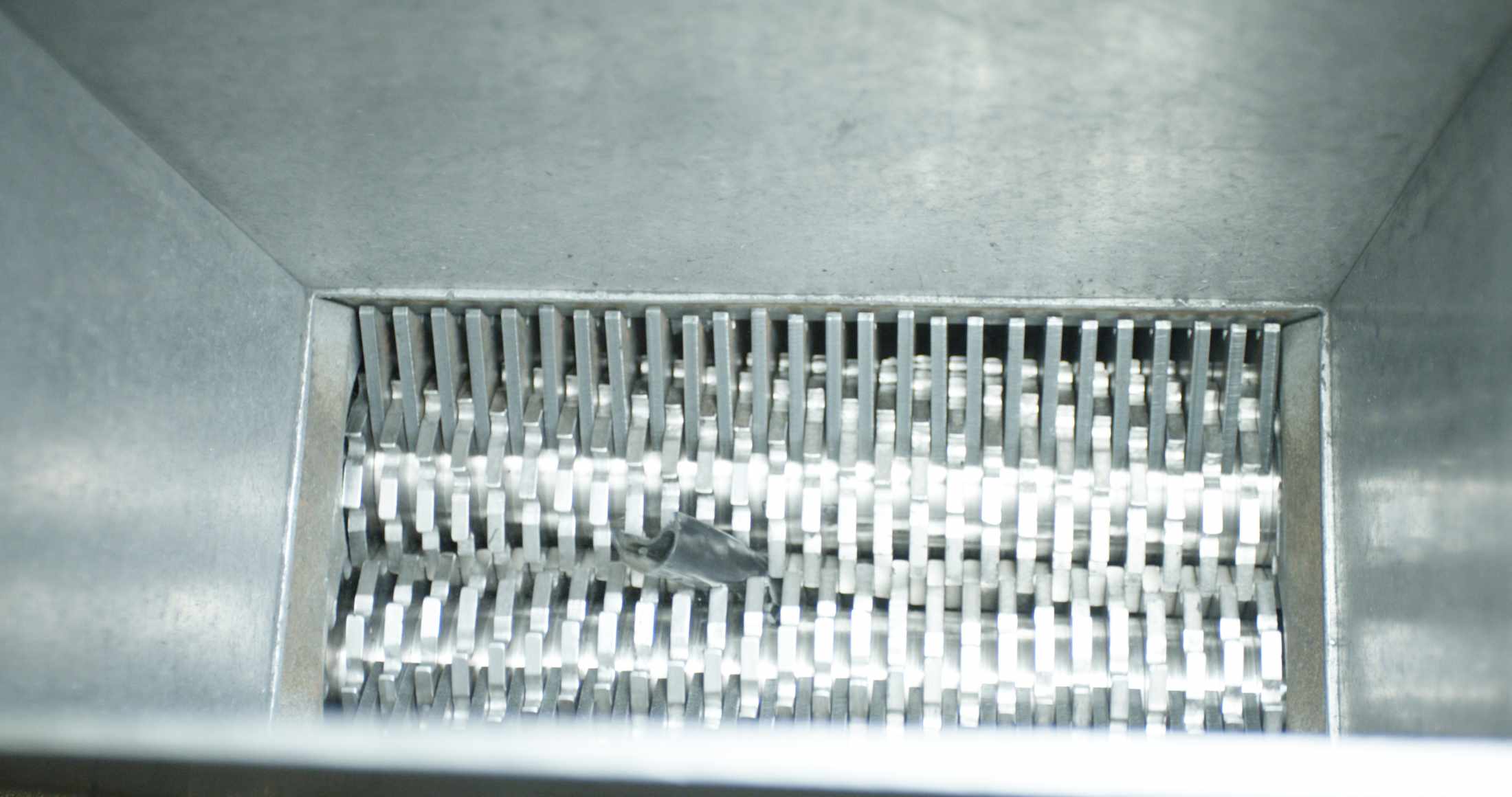

We remove the vinyl decals and drop the rim into a chipper and chop it up into small blocks about 1” square. Those chips are then melted down into a block of material that can be turned into another part. We’re thrilled to be taking tangible steps and working with the world’s leading manufacturers to create products made for fun and the least amount of negative environmental impact possible.

Of course, we’ve yet to see what these chips might be made into – the cynical among us may note the stockpiles of ‘recyclable’ plastics that sit in huge bales waiting to be turned into anything useful. Or indeed chips that can only be made into whale food style disposable plastic throwaway trinkets. Cynicism aside, chips that can be made into something are better than old rims that can’t, so it’s got to be a step in the right direction. It’ll be interesting to see what other applications the Fusion-Fiber material might be suitable for – handlebars maybe? Linkages? Whole frames?

Back to the rims. Of course, you’d probably prefer not to break yours and need to recycle them in the first place. Revel is confident of the strength of its RW30 Rims,

Fusion-FiberTM has multiple patents pending and is stronger and has much better impact resistance per gram than standard carbon fiber. Where epoxy is brittle and can fracture, nylon is flexible and makes for a quiet, damped ride feel, and better impact resistant rim.

And if the worst does happen…

Revel rims are backed by a lifetime warranty and crash replacement policy. If a Revel rim should happen to break, we want to get you back riding your bike riding ASAP. We want that rim back so we can recycle it into another bike part.

If you do break your rim, we’ll send you a loaner set of wheels at no charge to use while we repair or replace your wheel. We’ll cover shipping both ways. The bottom line is that in the mountain bike world, a lot of us have come to accept a pretty high failure rate for high end carbon wheels. We engineered these rims to be superior in strength to all other carbon rims on the market, but if you run low tire pressures, smack a sharp rock and luck isn’t on your side, a rim crack can still happen. The likelihood of our Fusion-FiberTM to contain a failure in a small area on the rim and not permeate a larger crack is high, and you have a better chance of keeping your tire on the rim and inflated if something does go wrong.

Revel took their sponsored riders to Fruita to make a promo video, where we can’t help but notice a distinct lack of rocks. Perhaps even our own rim smasher Ross could ride there without breaking anything? That said, there’s a series of slabby step downs that have a hairy scary layer of snow over them. Make sure you watch the video to the end to see the pros looking a little hesitant and mortal.

If you are interested in owning these wheels rather than just nerding over the technology, 27.5 and 29in wheels are available now. The RW30 is designed for trail and enduro use, and weights are 440g and 470g for the 27.5 and 29in rims respectively. Rims costs $699 per rim and come in 28 or 32 hole options with rim tape and valve stems installed.

Complete wheels come with Industry Nine I9 1/1 or Hydra hubs, and 28 Sapim D-light spokes. A pair of Hydra equipped wheels will be $2200, will Industry 9 1/1 hub wheelsets will be $1975.

I wonder how many of the most vocal carbon fibre critics on here drive everywhere, including to and from their days PLAYING on bikes?

Or buy bikes not made just down the road and outfitted with components made overseas or read magazines or websites that rely on people travelling to get the stories and photos?

All of us right?

Some people are trying to reduce the bad effects of our hobby.

Respect that rather than attack it.

The last section looks like the entry and exit to Horse thief bench, rode it last spring, and the steps are bigger than they look.

@notlocal I think you might be right – I recognised them but couldn’t put a name to them.

Sounds an awful lot like the thermoplastic carbon fibre that a few frames were made from in the 90s, eg GT STS.

Anyone know what the difference is?

Yes, sounds like a nylon or similar with long carbon strands in it, not bad but unsure how they will compare to woven carbon stiffness wise, likely less. Impressive weights for the rims above though.