It took Shimano years to jump on the 12-speed bandwagon, and now after just 12 months, they could ditch 12 for 13 and derailleurs for a gearbox.

Shimano tend to play the slow and steady game. They tend to keep a close eye on the market, check out what the competition is doing, what they’re doing wrong, then come along with something similar but usually better.

Just look at how long the Japanese giant took to release a 1 x 12-speed drivetrain as an example of how they prefer to move at their own pace rather than rush to keep up.

With that said though, a new patent discovered by BikeRadar does hint that Shimano might be ahead of a few of its main rivals and might be one of the first big drivetrain makers to launch a gearbox for use on mountain and road bikes.

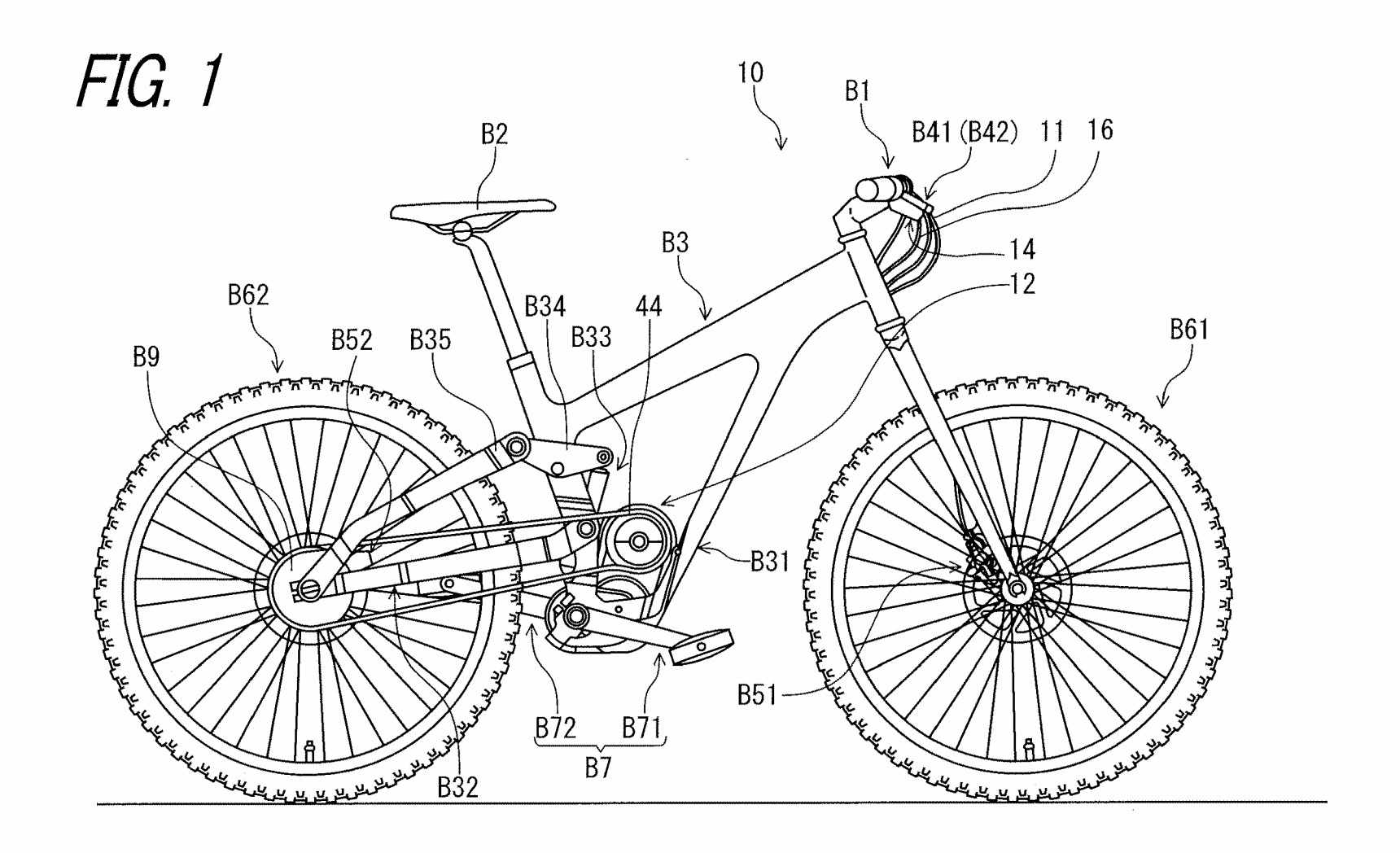

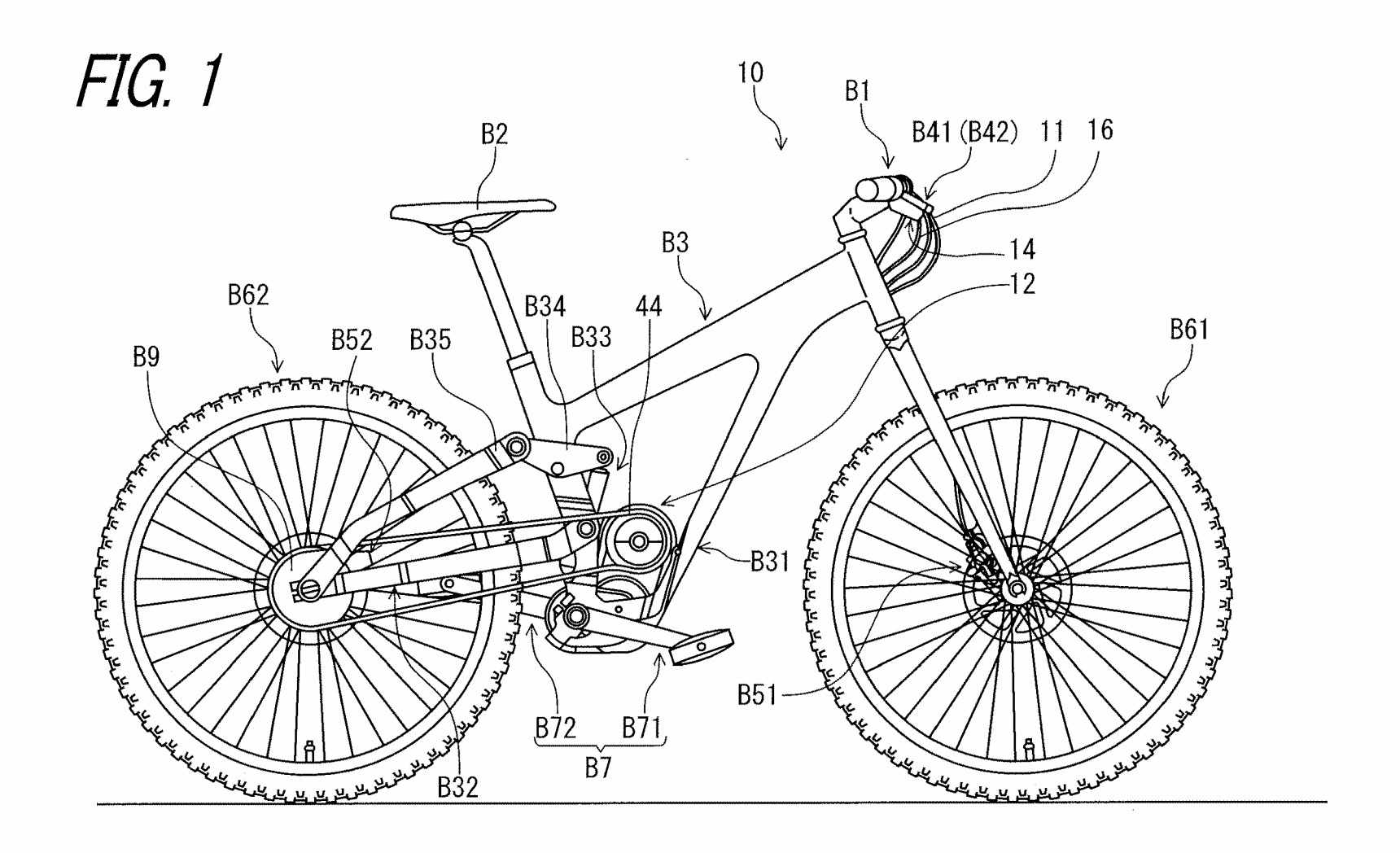

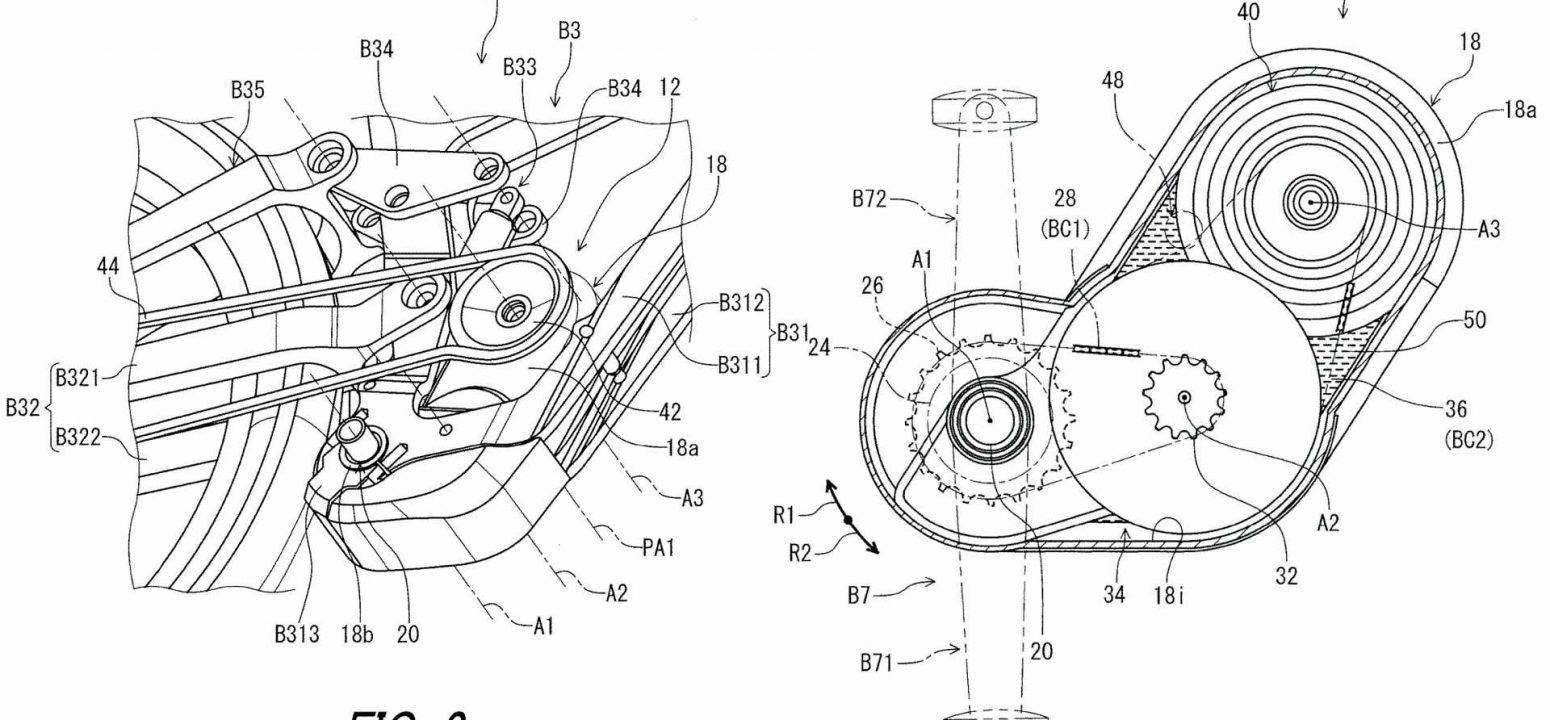

The Shimano gearbox patent was submitted in January of this year (2019) and clearly shows a self-contained 13-speed drivetrain that mounts to a frame in a similar fashion to the current Shimano Steps motor system.

Now as we all know, gearbox drivetrains are nothing new and various brands have tried to increase their popularity over the years. Honda had their nifty downhill bikes with compact gearbox, Suntour and Nicolai once had the Gboxx standard (where did that ever go?) and more recently Pinion and Effigear have been championing gearbox design for bicycles.

For mountain bikes a gearbox makes a lot of sense, after all, it means you no longer need a delicate rear derailleur hanging off the rear of your bike, you can move heavy components to the centre of the frame, and because everything is internal you shouldn’t need to worry too much about maintenance.

The problems with current gearbox designs though are weight, drag, and the inability to change gear while pedalling (on some designs) and these are some of the issues that Shimano’s 13-speed gearbox patent aims to address.

13-speed Shimano Gearbox Explained

This won’t be a full explanation of the system as the patent is purposely vague, but still, we can see a few details and can figure out how the system might work from the documents filled.

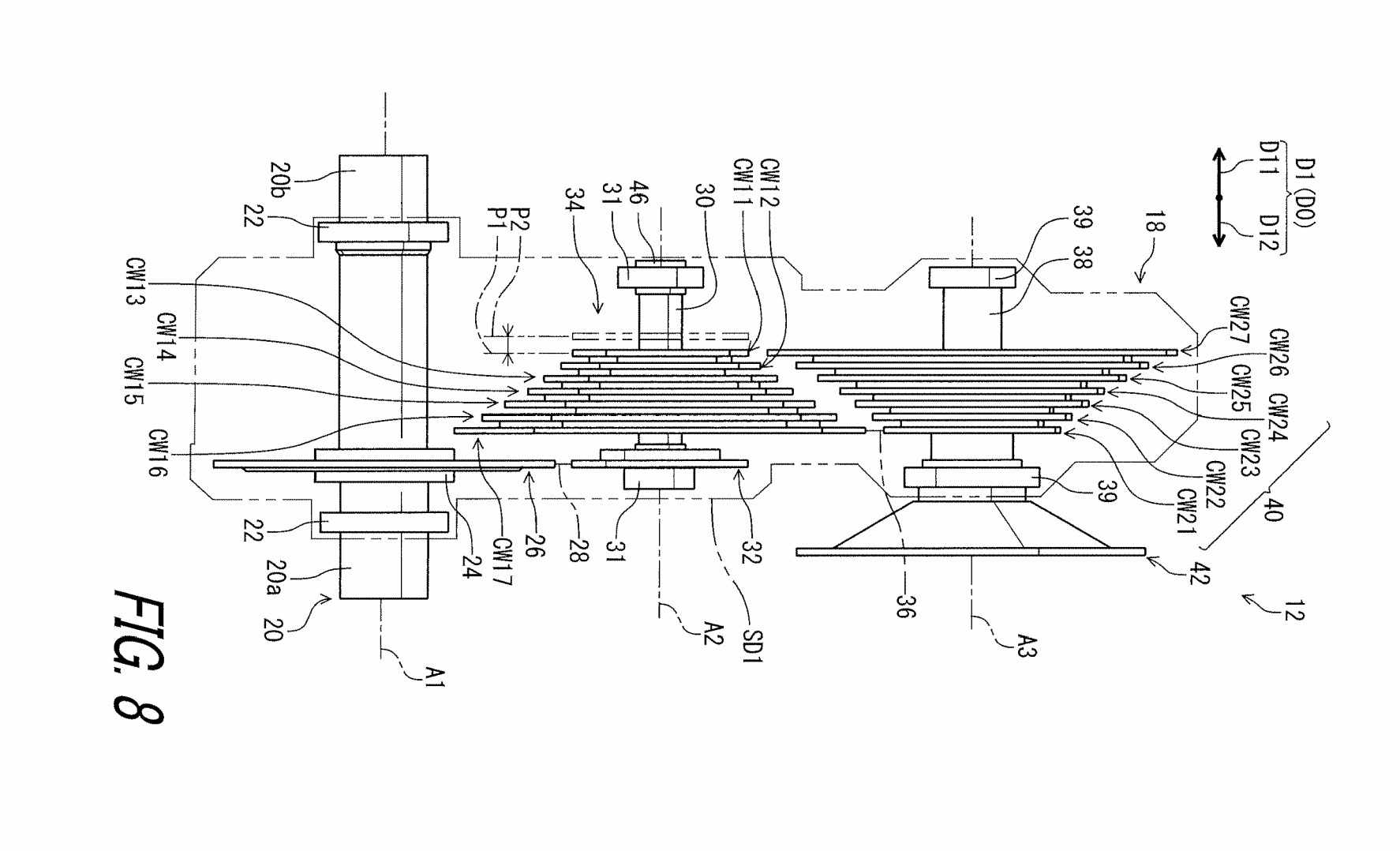

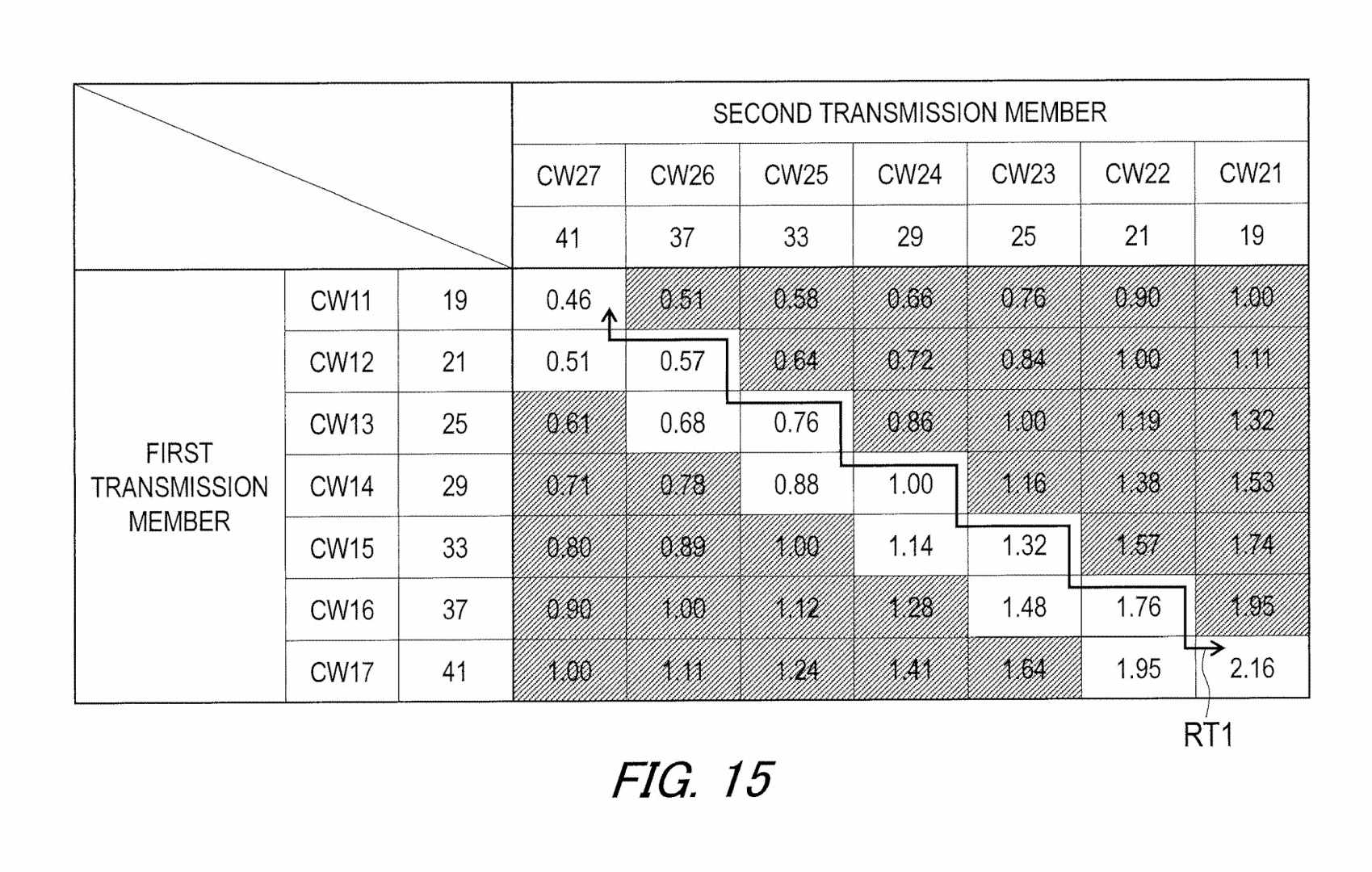

First of all, the Shimano gearbox isn’t like other gearbox systems currently on sale and is more similar to the Honda gearbox from back in the day. For Honda’s downhill bike, engineers built a small enclosed system that used a rear mech and cassette mounted centrally on the frame. Shimano new gearbox patent uses a similar idea but has 2 small cassettes located internally instead giving 13 speeds and a range of 470%.

These two cassettes are fitted with electronic actuators so that they can slide horizontally to shift from gear to gear. A small length of chain connects the two and because of the way the system is designed the chain is always perfectly aligned.

Compared to the interlocking gears found on a Pinion or Effigear system, Shimano’s patent does have the potential for less drag and could also possibly be much lighter in weight, however, all of those components do suggest a gearbox much larger to those we’re seeing already.

The patent goes on to tell us that the system can either be controlled electronically or via a cable similar to current gearbox and hub gear systems and that the gearbox could even be designed to offer a CVT style transmission.

We also wonder if Shimano’s gearbox patent as the potential to be fitted to an eBike too, after all the lower portion of the design does look the same as a Shimano Steps motor.

Although this patent was filed back in January it doesn’t mean that a Shimano gearbox is going to be arriving on the market any time soon, or ever for that matter, but is Shimano were to make a gearbox it could potentially change the face of mountain bike design.

Would you like to see more gearbox bikes on the market, or are you happy with the OG rear derailleur? Let us know in the comments below.

If you want to read more about gearbox bikes you can read our Zerode Taniwha review here, and Jason Miles review of this interesting Ti gearbox bike from Pilot here.

Comments (11)

Leave Reply

Post Comment

A lightweight, efficient gear box that works under load? Holy grail isn’t it? No more derailleurs to smash and replacement cassettes to buy. Heaven.

I might be tempting fate here, but after riding year round for 25+ years I’ve had so few problems with rear derailleurs that it wouldn’t really occur to me to look for an alternative if it wasn’t for articles like this. I still wouldn’t mind trying a gearbox though.

About time too! Hoping this has some legs and excited to see more developments

Yep, I’ve never smashed a rear mech (probably will this weekend now!), but still want to try one of these modern gearbox bikes. Love new tech stuff 🙂

You call the Honda gearbox ‘compact’? There might have been a complete derailleur system inside! Oh, wait, there was! 😉

Same as darlobiker and johnw1984, I have never even bent a mech hanger – thou customers to the service seem to not do much else but bend their hangers or smash their derailers into the drive side spokes of their wheels….

But yeah, would like a gearbox, especially for the e-bike, since that one eats chains so fast you barely get 500 km from one before it is ready to be replaced.

Agree with the holy grail comment – would love one. Lets face it, no more bent bits, less to clean, less to maintain…..

Filing a patent doesn’t mean they intent to use it, it could just the outcome of some research being filed for the sake of keeping the patent tally up. We used to get a bonus for each patent we filed at work, regardless of wether it was of any use; just a numbers game.

I suppose all the people who have never bent a mech hanger or destroyed a rear mech might look to the unsprung mass argument? For the rest of us that ride rock and steeper terrain why wouldn’t you want a gearbox? Less maintenance, less unsprung mass, less snappy off bits, weight more central and lower…

If they can get drag down to derailleur levels and electronic shifting then it will be massive.

Does the patent description describe how the internal chain is tensioned? As most of the internal sprockets are used with more than one partner sprocket, there must be some mechanism taking up the slack.

@ChrisL – magnets