For the second round of the 2017 UCI Downhill World Cup, all sorts of new bikes and components are being put to the test on the unrelenting Fort William racecourse. As you will have seen from our coverage yesterday, loads of teams are testing out prototype race bikes, including the Intense Factory Racing team.

We dropped by the Intense Factory Racing workshop to check out the prototype bikes, and to chat with Jeff Steber; founder and lead designer of Intense Cycles, and fan of all things haggis-related.

Like several other brands, the Intense Factory Racing team is putting 29in wheels to the test at Fort Bill, with team riders Jack Moir and Dean Lucas piloting alloy 29er prototype frames for the weekend’s race action. Intense has long dabbled with wagon wheels for full suspension bikes, including a 29er downhill bike that Steber built way back in 2009. While the 2951 was more of a concept bike – and somewhat lacking for suitable components at the time – it would seem that the concept had merit, given that 29in wheels are currently the hot topic of conversation on the World Cup Downhill race circuit. Jeff told you so.

Fast forward eight years, and Intense is now ready to put the big wheels onto the race course with this stunning raw alloy prototype. But although the frame shares the same 29in diameter wheels as the original 2951, in reality the new prototype is a far cry from that early concept bike.

The frame uses a dual-link suspension design like the current M16 downhill bike, but the orientation and size of the two linkages is significantly different. The upper link is neatly tucked inside the seat mast of the alloy frame, and guides the upper seatstay throughout the 8in of travel.

In order to preserve a short rear centre length with the 29in wheels, the lower linkage pivots around the bottom bracket, and uses an extension that drives the rear shock low down in the frame. It’s all very low-slung and compact for a bike with this much travel and this size wheels and tyres.

The frame is welded by Jeff Steber himself in Temecula, Southern California. Although Intense is no longer producing alloy mountain bike frames (the brand will be working exclusively with carbon fibre for production frames moving forward), Steber still has his own machine shop for building and welding up alloy mules for testing purposes. The downhill bike you see here is the product of Steber’s workshop experimentation, and the frame is left with a raw finish so that Steber can re-weld the tubes to make any modifications required.

For a close look at Jeff’s prototyping and an in-depth interview from Chipps’ visit to Temecula after this year’s Sea Otter, be sure to check the next issue of Singletrack Magazine that’s out this coming week.

Aside from the purpose-built frame, there was plenty more required to get this bike ready for World Cup level competition. Drawing on the race team partners, the prototype is running proper 2-ply downhill tyres from Maxxis, along with burly handmade M90 carbon rims from ENVE. The forks are a custom item from RockShox, being a hybrid dual-crown number that’s made with Boxxer uppers and internals, with Lyrik 29er lowers that provide sufficient tyre clearance to fit the big 29in rubber. Word on the street is that a dedicated Boxxer 29er isn’t that far away…

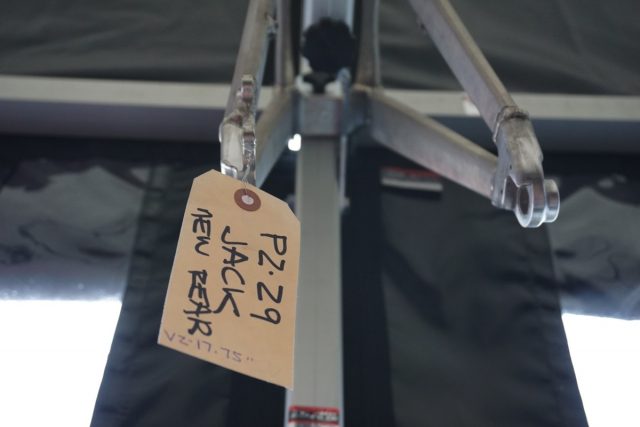

In the Intense Factory Racing pits, there were two different prototype 29ers set up for team riders. The all-raw frame you see here belongs to a young Jack Moir, who finished today’s qualifying round with the 3rd fastest time of the day. According to Steber, the lads are taking to the new bike very, very well.

There are several versions of the prototype frame, with P2 and P3 on display at Fort Bill under Dean Lucas and Jack Moir. Steber indicated that he’s already planning the next generation prototype, and will likely continue to refine the concept before reimagining the design in carbon fibre for a production bike, which could be less than 12 months away.

Although Jack Moir and Dean Lucas’s race bikes are still in prototype form, they’re looking darn good already. Although the prototype may not be a sleek carbon fibre future-machine, we actually quite like the look of the raw un-painted alloy tubes and chunky welds.

But as we all know, looks mean nothing when it comes to racing. The results of the real litmus test will be discovered tomorrow, and everyone will be watching in anticipation.