- This topic has 47 replies, 18 voices, and was last updated 14 years ago by simonfbarnes.

-

To face or not to face

-

z1ppyFull MemberPosted 14 years ago

Just got a new frame (2nd hand) for a m8, and it's not been faced (paint on the outer shell), which I'm, gunna fit some deore HT II cranks too. So without any arguements, face it or not: Yes/No

I've had it done to my bikes in the past, but this is a budget build, so a £10 spared is a £10 off the total cost for my m8! (he's totally skint and on a limited working wk) Question is really does anyone think the long term life of the bearing will be compromised?

bristolbikerFree MemberPosted 14 years agoHow much is a replacement Deore quality HTII BB going to be – £20 ish? So the cost of facing is going to be around 50% of a new BB.

If he's going to ride it lots, so the rate of wear on the bearings is potentially higher then it may be worth doing. If it's for occasional use, so the bearings don't see much wear anyway, then prob not worth doing and live with the replacement cost at some point in the future.

However, if it was me, then yes – £10 well spent

mrmoFree MemberPosted 14 years agoyou might not need it doing, the frame may be fine without facing, but then again it might not be fine. For the small sum it will cost you might as well.

I_AcheFree MemberPosted 14 years agoIt doesnt matter on little bit. The only possible advantage that I can see is that the threads of the BB will be 1/2 a urn further in MAX and if using HT2 the NDS arm will be less than 1mm further on the spline. Like I said no difference at all.

Actually there might be a slight difference. The BB might be faced too far so that with a HT2 style setup you could get the tinyest bit of horizontal play in the axle because the BB cups are inserted too far ie 67mm not 68mm.

Waste of money.

tragically1969Free MemberPosted 14 years agoIt doesnt matter on little bit

i think you are missing the point ?

Its not about BB shell width, its about getting both faces square so the axle is in line with the bearings is it not ?

clubberFree MemberPosted 14 years agoBB facing tools (at least most of them) don't ensure that the two faces of the BB are parallel to each other – only that they're in line with the BB threads on each side. If you trust the frame manufacturer to get the threads on each side in line with each other, why not trust them to get the faces right?

I still reckon the whole facing thing was an excuse not to warranty replace a lot of the original HT2 type bearings which weren't up to the job because of either poor sealing or just cheap components.

simonfbarnesFree MemberPosted 14 years agoit's about saving face for the Shimano engineers who made the threads on the cups too short to ensure alignment 🙂

clubberFree MemberPosted 14 years agoInteresting theory SfB – hadn't thought of that one.

not sure you're right though – the way that the cup sits against the BB face will determine the alignment I'd reckon rather than the thread

I still think you could improve it further by making the cups lock into each other rather than in the frame. It'd be great for frames with knackered BB threads too.

I_AcheFree MemberPosted 14 years agoYes but the facing tool uses the threads to line itself up does it not? Therefore if the threads are in the shell at the correct orientation to provide a perfectly faced bb shell then the bb will also go in at the same angle.

If one of the threads is at say 90deg to the face of the shell and the other is at say 88deg then no matter what you do short of stripping the thread and helicoiling it you wont get a straight bb. As long as both threads are 90deg from the shell face then you will be fine and if they arnt there is no point facing it as the frame is knackered.

So as i said all facing does is move the bb cups closer together.

I hope people understand what I'm trying to say.

foxyriderFree MemberPosted 14 years agowhat frame is it? – I expect it maybe faced beneath any paint that may be present – ID the frame and email the manufacturer and ask them as it may save to a few quid!

nickcFull MemberPosted 14 years agoSpacers in HT11 BB's are plastic. Some-one once on this site tried to persuade me that it was some sort of special super hard plastic that didn't deform or some such other bollards…

Makes no difference.

glenpFree MemberPosted 14 years agoI agree that if the two threads aren't aligned then the square-ness of the faces makes no difference. Its not as if the last mm of turn will twist the face of the BB in relation to the thread.

Best advice with external BB is keep the hosepipe well away from external bearings.

foxyriderFree MemberPosted 14 years agoI_Ache – ant see your logic there – I don;t think you threads would be anywhere off 90 degrees at you would have to burrow thought the presumed straight BB shell – I can't think the shell is variable in thickness or welded wonky – BB facing is ensuring hte outside face is square with both the threads and thus the shell surely? 🙂

tragically1969Free MemberPosted 14 years agoSo as i said all facing does is move the bb cups closer together.

I am afraid you are off the mark with that comment, its all to do with getting the bearings in line as best you can

This is what park have to say on the matter:

Additionally, some bearing system benefit from having the faces of the shell square to improve bearing adjustment and bearing longevity. If the shell faces are deformed, and are not parallel to one another, the left and right bearing may not be concentric to one another. Machining the shell face improves concentricity.

simonfbarnesFree MemberPosted 14 years agoand the other is at say 88deg then no matter what you do short of stripping the thread and helicoiling it you wont get a straight bb

I thought that too, but I'm told the cup threads are short enough that the cup can rotate relative to the thread alignment as they are not a perfect fit against each other (you can practice this with a nut and bolt – the nut can wobble)

I_AcheFree MemberPosted 14 years agoOne other point.

Aligning the whole frame cant be that easy, not something most of us could do. But most of us could take a big laser guided saw and push the big green start button that cuts the lengths of tube used for the bb shell and sit back and read the paper for the rest of the day.

Why trust them to align a whole bike but not cut a tube of metal to the right length and at the right angle?

And even if the BB shell hasnt been cut straight at both ends the BB would just sit against the bit thats furthest from centre as you wont be able to screw it in any further.

I_AcheFree MemberPosted 14 years agoThats a good point sfb and one that I hadnt considered. But the threads are pretty close together and there are a lot of them so it shouldnt be an issue. Next time you have a crank off undo your bb a bit and try to wiggle it I'm pretty sure it will be fine.

poppaFree MemberPosted 14 years agoIf the plastic spacers deform it's not going to make up for misaligned BB shell. The BB is usually fitted with a reasonable torque. If the plastic spacers deform it is not going to be such that they magically align the BB halves in a perfect fashion.

I_AcheFree MemberPosted 14 years agoOh and this is a load of crap because if the threads arnt parallel then no matter what you do the cups wont be concentric to one another. Just closer.

Additionally, some bearing system benefit from having the faces of the shell square to improve bearing adjustment and bearing longevity. If the shell faces are deformed, and are not parallel to one another, the left and right bearing may not be concentric to one another. Machining the shell face improves concentricity.

poppaFree MemberPosted 14 years agoAnyway, based on the advice here I would toss a coin and then grumble/don't grumble when your BB dies early/lasts ages.

My experience is limited, but I got my BB shell faced and my first HTII BB has lasted about 1yr and counting with no problems whatsoever. I am a believer.

poppaFree MemberPosted 14 years agoOh, and the whole argument for facing assumes that your BB threads are aligned but that the faces of the BB shell might not be even/parallel. If your threads are not aligned then you're stuffed in any event. Like other people have said, you would hope that the faces of your BB would be made parallel at manufacture, but if your frame has paint on the surface of the BB shell then giving it a quick skim with a BB facing tool would be a good idea IMO.

simonfbarnesFree MemberPosted 14 years agoNext time you have a crank off undo your bb a bit and try to wiggle it I'm pretty sure it will be fine.

I would were it not for the fact that I've seen so many reports of short life on external BBs I'm still using sq. taper 🙂

poppaFree MemberPosted 14 years agoWhy am I putting so much time and effort into this? I really must do some work… 😳

I_AcheFree MemberPosted 14 years agolol I on the other hand round off sq taper and destroy bearings in isis/HT1 and the only bb/crank combo that I havn't ruined is the Hone that was on my Enduro when I sold that. 2.5 years on 3 frames with no maintenance or facing and the bearings were still fine.

tragically1969Free MemberPosted 14 years agoOh and this is a load of crap because if the threads arnt parallel then no matter what you do the cups wont be concentric to one another. Just closer.

I hope to hell you are not an engineer, if you are we are all ****.

HammerFree MemberPosted 14 years agoOn a budget build (and on most other builds for that matter) I would settle for scraping/filing the paint off the BB faces. Some wet and dry wrapped around a file will clean off the paint, which could otherwise be squashed and crack causing the BB to come loose or move around.

BB facing tools in my opinion are rarely as good as the guy using them, and this compared to the CNC machine that would have machined and threaded the BB interfaces to begin with, chances are you'll only make any misalignment worse. Waste of time and money.Any slight misalignment in the BB interfaces/threads will be easily accomodated within the BB bearings and axle tolerances.

Remember, it's only a bicycle, not a jet engine or a swiss watch!

Ham.

simonfbarnesFree MemberPosted 14 years agoOh and this is a load of crap because if the threads arnt parallel then no matter what you do the cups wont be concentric to one another

and

I hope to hell you are not an engineer, if you are we are all ****.

well, it may be that if the threads were not parallel, if the cup threads were short enough it might be possible to get them to line up if the faces were machined parallel, however no one has told us how likely it is for the threads to be non parallel. One might hope the original machining would be done with a jig to enforce this, otherwise it would depend on the original parallelity of the faces 🙁

I_AcheFree MemberPosted 14 years agotragically, no I'm not are you? And if you are can you show me some evidence that is from an impartial source and not a manufacturer of parts that 'require' facing or a manufacturer of tools that 'face'.

I will put it in simple terms.

If the two sides arnt pointing at each other they wont meet.

Edit: By require facing I meant that the BBs require the facing of a frame. And the tool manufacture I was talking about is Park as that is who the quote that tragically used is from.

ballsofcottonwoolFree MemberPosted 14 years agodon't face it and don't buy hollowtech II, get a proper BB instead.

simonfbarnesFree MemberPosted 14 years agoI suspect the whole facing thing is crapdoodle – after all, the forces of pedalling and riding deform the frame probably as much as the supposed small misalignments discussed…

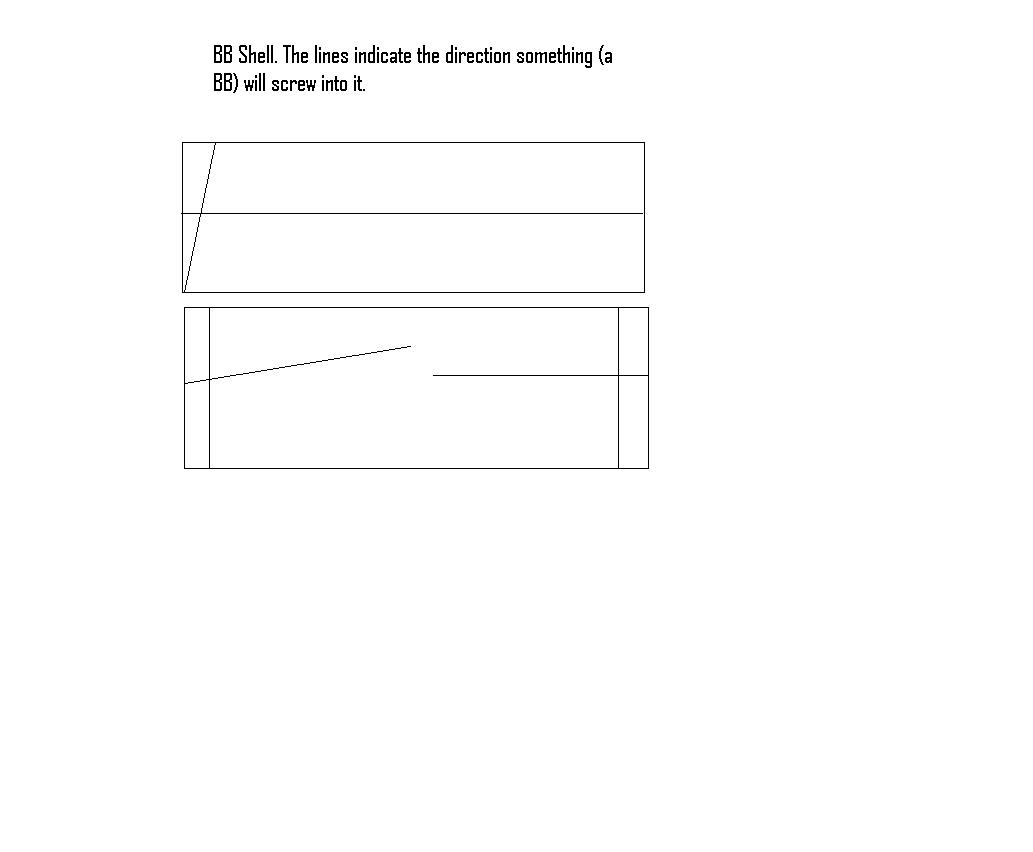

I_AcheFree MemberPosted 14 years agoThis is a crappy paint image I have knocked up.

The top pic shows that if both threads are parallel then the BB will be aligned the diagonal line on the left of the first pic shows that if the face of the shell isnt 90 deg to the thread then the bb cup will just stop at the outermost point. Although sfb does have a point that the cup *could* twist here but only if the difference is severe and if it is overtightened.

The second pic shows that if the threads arnt parallel and you face the bb shell it just moves the cups closer together.

kempfabFree MemberPosted 14 years agoThis question has always intigued me.

I have always assumed frame manufacturers simply make BB's finish tapped, then fabricate frame, and with all of the welds on less than 2/3 the diameter, they inevitably distort, proven on most by placing a straight edge across the bottom edge. However, my latest steel frame, which is distorted as expected, the BB cups clearly hit one point on the face first, suggesting it was tapped/threaded after fabrication?

Anybody been to a frame manufacturer?

Anyway, I am going to file mine, and check using feeler gauges, that should waste some time…tragically1969Free MemberPosted 14 years agoAnd if you are can you show me some evidence that is from an impartial source and not a manufacturer of parts that 'require' facing or a manufacturer of tools that 'face'.

Well that might be difficult really dont you think ? But is Sheldon Brown good enough ?

Facing

The process of finishing the flat surfaces of the frame and fork to which bearing assemblies attach. Correct facing of the head tube, fork crown, and bottom bracket shell ensures correct alignment of the headset and bottom bracket bearings. This is necessary to ensure good bearing performance and reliability.z1ppyFull MemberPosted 14 years agoballsofcottonwool – Member

don't face it and don't buy hollowtech II, get a proper BB instead.No I'd rather have a HT II BB as there easily installable (not specific to a frame or crankset), easily removable, is stiffer than any previous BB's and for the most part just work (3 years in and 3 bikes with them & all my m8's run them).

Oh well so much for the OP asking for Yes/No answers and no arguing.. though Bristolbiker has made the most valid point… hmmm bugger still don't know what to do.

I_AcheFree MemberPosted 14 years agoI accept that facing of the head tube and crown *may* be necessary but that isn't really evidence just an opinion. Didn't Shedon Brown used to work at a bike shop?

tragically1969Free MemberPosted 14 years agoDidn't Shedon Brown used to work at a bike shop?

How the hell do i know that !!

Anyways, i would personally get it done for the sake of a tenner !!

The topic ‘To face or not to face’ is closed to new replies.