- This topic has 16 replies, 12 voices, and was last updated 14 years ago by coffeeking.

-

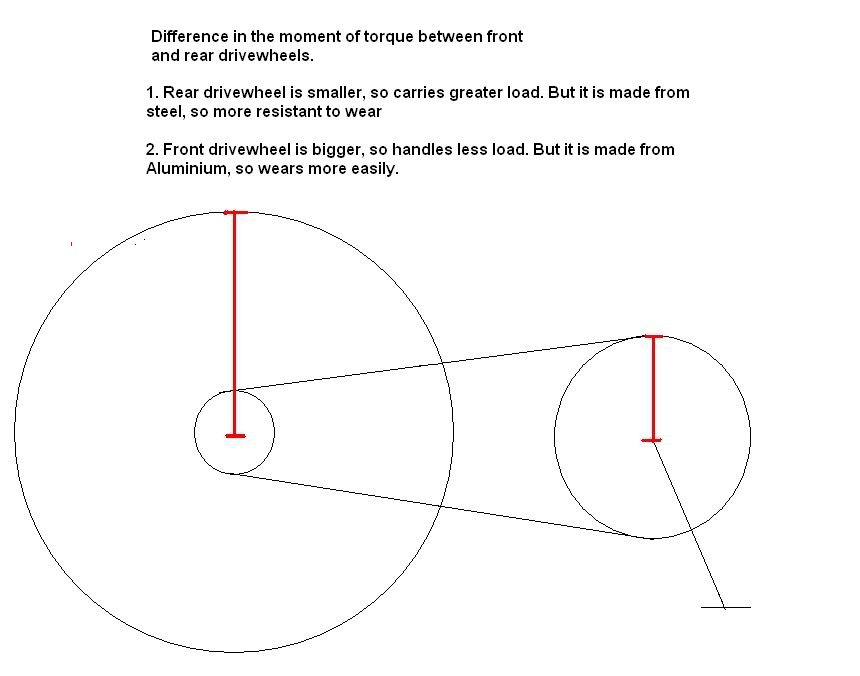

Engineery types… is this diagram correct?

-

no_eyed_deerFree MemberPosted 14 years ago

I created this in a bored 5 mins to help a non-biker understand why drivetrain bits wear at different rates, but is it correct?

spooky_b329Full MemberPosted 14 years agoThe chain wears fastest, and stretches. Once stretched, everything will wear out. Solution = buy a chain checker and replace chain regularly. Drivetrain will last much longer.

robdeanhoveFree MemberPosted 14 years agoThere's no such thing as a "moment of torque" you can have torque, or you can have a moment.

Your explanation is completely incorrect too. The "load" carried by both sprockets (not "drivewheels") is the same, this is the tension in the chain, which must, necessarily be the same. at the interface between the front and rear sprockets. ref. newton's 3rd law of motion.

The rear sprocket will see a greater contact pressure between the sprocket teeth and the chain due to the reduced contact area offered by the lower number of teeth in contact with the chain. This makes the rear sprocket more prone to wear. the rear sporcket is NORMALLY (not always) made of steel, which is harder than the aluminium used for the front sprocket, so will wear less when used with a steel chain in this application.

The converse is true for the front sprocket, more teeth, so less contact pressure (although the tension in the chain is the same), but normally made from a softer aluminium allow, so tends to wear more quickly.

Also, you should make the more important point that, with an 8, 9 or 10 speed cassette the rider will normally spend a lot less time in each of the rear sprockets than he will in his front sprockets where he will have, typically, 2 or 3. This is probably the greatest driver for middle ring wear as most riders with a triple chainset may spend >75% of their time in the middle ring. Hence the middle ring will wear first. This was nicely demonstrated when I lived in the Peak a steel middle ring would always wear faster than my cassette in winter for this reason. An aluminium granny ring would last longest as it was used, but not nearly as much as the middle ring.

Your diagram is wrong too, the radius of the rear wheel, that you have highlighted, has nothing to do with drivetrain wear forces, these remain the same no matter what the wheel size, assuming you are pedalling with the same effort. Wheel size merely effects the gearing between your pedalling and the speed of the bike. i.e. double the wheel diameter and pedal just as hard (same amount of energy output) and you will percieve the identical effort, but your cadence will be half, the drivetrain forces and wear rates will remain the same, but the wheel, and your cranks, will be going at half the speed for the same force, given the same resistance from the bike i.e. headwind, gradient etc.

petefromearthFull MemberPosted 14 years agoas above! you don't get more concise than that rob

the only thing i'd add is … not only does each tooth on a small rear sprocket experience a higher contact force, it will see that force more frequently than the large chainring, since it'll be rotating faster

NezboFree MemberPosted 14 years agoas spooky says stretching chain will ware your rings and casset more brcause the chain is not sitting correctly.

rootes1Full MemberPosted 14 years ago<<as spooky says stretching chain will ware your rings and casset more brcause the chain is not sitting correctly. >>

chains do not stretch as such well not in the true meaning of the word, but the rollers and pins and holes wear introducing bigger gaps between the elements and thus the length of the chain grows when in tension as the elements moce to suit the increasing gaps.

no_eyed_deerFree MemberPosted 14 years ago…Ah brilliant, as I always knew.. A little knowlege is a very, very dangerous thing! I see that I was utterly deluded in thinking I knew what I was talking about… And not for the first time this lifetime 😛

Thanks for a clearing that up!

smiffyFull MemberPosted 14 years agousability of worn parts depends on the amount of contact and wrap, too. a very slightly worn granny ring will cause all sorts of grief and require binning, a big outer ring with lots of contact and a less wrapped chain will work perfectly well with worn, missing and bent teeth. I refer to my own bike as testament to this.

spooky_b329Full MemberPosted 14 years ago<<as spooky says stretching chain will ware your rings and casset more brcause the chain is not sitting correctly. >>

chains do not stretch as such well not in the true meaning of the word, but the rollers and pins and holes wear introducing bigger gaps between the elements and thus the length of the chain grows when in tension as the elements moce to suit the increasing gaps.

Pedant 🙂

j-cruFree MemberPosted 14 years agoChain side plates do indeed stretch, when you next change a chain lay old and new side by side. For an equal number of links the old one will be longer.

spooky_b329Full MemberPosted 14 years agoI'm going to have to side with Rootes here, the 'stretch' is actually the rollers and pins wearing, creating slack that allows the chain to increase in length.

If you take that worn chain that is longer for the same number of links, and instead of pulling it tight, work along the chain and push all the links together, it'll be shorter than the new chain. The new chain won't have any noticeable difference in length if you pull it tight or push the links together.

rootes1Full MemberPosted 14 years agosorry wasn't trying to be a pendant, but seeing as this was a thread concerned with the transfer of engineering knowledge – seemed in this case worth making the point. 😀

robdeanhoveFree MemberPosted 14 years agoHe's right, they don't stretch, it is the rollers and pins wearing, just like it says up there.

scotiaFree MemberPosted 14 years agoj-cru – Member

Chain side plates do indeed stretch, when you next change a chain lay old and new side by side. For an equal number of links the old one will be longer.

have you tried this with just two link-plates (one old one new) to compare?!

pretty sure you'll find its the wear between plates and pins that does it..

coffeekingFree MemberPosted 14 years agoAs above, chain link plates do NOT stretch permanently in this application (it would take HUGE forces to cause plastic deformation). You're mis-interpretting the way the chains are assembled which means you're thinking the plates are rigidly connected by the pin and therefore any increase in length must be stretch. This isnt the case, only the outers are directly linked to the pins, the inners ride on bushes which wear and develop play, meaning the two halves of a link can move relative to each other, making the chain appear to stretch. This inner diams of 4 and 7 in this diagram are what wear, causing 6 to move relative to 5.

The topic ‘Engineery types… is this diagram correct?’ is closed to new replies.