- This topic has 61 replies, 24 voices, and was last updated 7 years ago by epicyclo.

-

Calling all engineers, why no high performance steel MTB rims?

-

gaidongFree MemberPosted 7 years ago

After my latest prang…

… I got to wondering why we can’t buy high performance steel rims? I’m not imagining that dented steel rims can’t happen but maybe they would resist deformation better and be more repairable? I’ve long enjoyed Cy (Cotic)’s geek section, where he gives an engineering explanation for his design choices, particularly for the Rocket. Could anyone please explain to me at what degree of hard usage a steel rim’s greater strength and stiffness might justify the extra mass?

I get it, XC rims for 65 kg athletes with great handling skills are best made of carbon/alu, but how about for a 90 kg porker who keeps hammering through the rocks and getting their bunny hops and jumps wrong? I’m ending up buying DH tyres, not so I can do anything super gnarly but just because I can’t afford to be rebuilding wheels all the time. *yes, I’m sure some will tell me to put the money into skills courses*

Could aluminium rim’s complex shapes be imitated in steel (I’m guessing stainless of some grade) or would they even need to have those same shapes to get the required stiffness? I’ve got a 20 year old Physics A-level (B!) and work in a very abstract field of metallurgy so might be able to follow some sort of calculation based answer, if you’d be so kind to give one!p.s. yes, that is a Lego pirate ship in the background at my office…

andylFree MemberPosted 7 years agoYou could make one but to be competitive weight wise it would be coke can thick and I dont think that needs any explanation.

It’s all about material density and stability to local impacts. Thin wall high strength and stiffness is all very good until you add a localised impact.

ghostlymachineFree MemberPosted 7 years agoI would think that to get the weight competitive the walls would be so thin you’d not be able to extrude a shape that complex, without going to some super exotic steel alloy. Which would need to be pliable and easily extrudeable. Which would make it a bugger to build into a wheel, and quite easy to bend. If you see what i mean. So you’d have to go thicker, and heavier. And you’d still end up with sticky up bits of rim that’d be easy to dent. And it’d be very expensive. And you might need to muck about with heat treatments and….. oh god, lets just use aluminium……. 😉

And that’s a grail isn’t it? Wide, deepish, lightweight racey CX rim? And that looks like some nasty, heavy commuter tyres…… You might be better off with something heavy (500g or more) and boring from mavic/velocity/etc for commuting wheels…… might be a bit tougher, and cheaper to replace if it does go.

cannondalekingFree MemberPosted 7 years agoI’ve quite often pondered about titanium rims double wall construction with stainless eyelets not built round weight weenie but for touring in a massive loaded bike off road kinda way.

Also stainless hub body’s and freehub

gaidongFree MemberPosted 7 years agoHi Ghostly. Yes it’s a Grail. When the wheel was built (Rohloff hub) I said it was for commuting with a spot of kerb jumping to get through the traffic – just that that kerb bit back! Tyre is a Conti Sport Contact 2 37mm. I’m replacing the Grail with a Mavic A319 (first wheel build attempt…)

But I’m specifically talking about MTB wheels here. I’ve fatally dented a WTB Laser Disc, an XT M785 and done a good job on a DT E1700 (straightened and still airtight. I don’t race and I’d be prepared to take a weight penalty for the confidence of knowing my rims are bit more resistant. I’m wrapping the E1700s in DH High Roller 2s for the Alps at the end of July.

Have the advances in steel alloys in recent decades not meant that we can make better steel rims; not the lightest but with a good security pay off?

andylFree MemberPosted 7 years agoTitanium is still denser than aluminium so you would probably still end up heavier.

I wonder what a carbon reinforced PEEK rim would be like.

bob_summersFull MemberPosted 7 years agoI don’t remember steel rims being heavy as such; I remember them more for their shocking braking, which you’d negate with disc brakes. Weren’t steel rims rolled rather than extruded? Pretty sure I’ve seen them being made on one of those old pathe films.

foomanFull MemberPosted 7 years agoI don’t think the rims are the problem 😀 some other options; more pressure, Pro Core, solid tyres, or change your riding style.

gaidongFree MemberPosted 7 years agoHi Fooman, I know that the rims aren’t the source problem but I can’t magic myself better and it’s getting expensive on the way to improvement! I don’t run very low pressures. Those commuting tyres would have been at 5-6 bar. Once the Contis are done I do plan to get some Tannus solid 32mm for the commuting but that doesn’t solve the MTB issue.

kerleyFree MemberPosted 7 years agoIf you don’t run low pressures on MTB and use big, high volume tyres how are you managing to dent the rims?

What pressures are you using and what tyres?

I have only dented one rim in my life and that was via a cocked up kerb hop on a 700c rim with 25c tyre (doesn’t matter how high the pressure in that case the kerb will still get to the rim).

gaidongFree MemberPosted 7 years agoHi Kerley,

WTB Laser Disc with WTB Bronson (as stock). 2.2″ I think. Rear wheel. Probably had 3-4 bar as it was early days back to mountain biking. There may have been a fault on that rim as it just exploded JRA, fracture right across the spoke hole.XT 785 with Conti Mountain King 2.4″. Rear wheel. Around 2 bar. Was descending a pebbly trail slower than my friends when I suddenly flatted (snakebitten tube) and found the rim section crushed (not just bent rim but the round section deformed).

DT E1700 with Maxxis Minion DHR2 EXO tubeless. 2 bar. This was just a messed up jump of a drainage channel. Not square edged but angular and the rear impacted making that very nasty noise. I could straighten this one and for downhill I’ve just bought HR2s with DH casing.

I know I need to learn my bunny hops etc but I’d still be interested to know whether much tougher rims are available, and why can’t they be done in steel.

Cheers.

gaidongFree MemberPosted 7 years agoHmmm, for road bike/29ers this company might have something – http://www.dutchbikebits.com/traditional-bicycle-wheel-rims.

Rims are marked 28 x 1 3/8 (622) in stainless. But would they be strong or just heavy?!

DaffyFull MemberPosted 7 years agoI wonder what a carbon reinforced PEEK rim would be like.

Flexible.

badbobFree MemberPosted 7 years agoso you had a flat that caused damage to a rim, a odd/heavy impact that damaged a rim, a possible structure issue that failed the rim

cant see what the problem is ? steel wont help, as the next weakest part will be the issue , spokes?

gaidongFree MemberPosted 7 years agoSpokes are already stainless steel! No, my thinking is that if I accept that I am a graceless beast, at least have rims I can straighten more easily without that nasty alu fracture characteristic.

badbobFree MemberPosted 7 years agospokes break at the nipple or shoulder, then the hub!

dt swiss rims normally known for being soft, but not all of the range? maybe look there

bigad40Free MemberPosted 7 years agoI can’t speak for rim material but I weigh 110kgs and ride a Hardtail down things faster than your average (weight) rider.

I used to mash wheels and frames on a regular basis.

Everything changed on my second visit to the Alps when I ran out of money to buy new brake pads after melting 2sets in almost as many days.

I had no choice but to ride with almost no brakes and was forced to keep it smooth, pick good lines, anticipate well in advance and follow classy riders. Now I just go through saddles, I have even bent a Thompson seat post!

Quality wheel builders are worth their weight in gold and I’m looking forward to a pair of 29er wheels being built next week to replace the factory set on my new (second hand) Scott Scale.

Skills courses are also just damn good fun.gaidongFree MemberPosted 7 years agoI did a skills course last year in the Alps but it was €35 an hour!

cynic-alFree MemberPosted 7 years agoInteresting thought OP.

I guess the culture has been aluminium for braking (I guess metal matrix was too hard to extrude) so there’s been no thinking around it.

I doubt wall thickness would be an issue – it isn’t on steel frames 🙄 I imagine it’s a combo of no one thinking about it and/or the expense/difficulty of extrusion.

And would there be any benefit? Alu frames are lighter than steel by a way.

mickmcdFree MemberPosted 7 years agoI wonder what a carbon reinforced PEEK rim would be like

Such things exist ,not for a bicycle at this time but it wouldn’t be a big jump from one industry that’s tried it to another.

EuroFree MemberPosted 7 years agoBound to be something like these about for mountainbikes. Skyways do 24″ wheels and there was talk a few years back of a 26″ version. Perfect for heffalumps.

if I accept that I am a graceless beast

That’s the spirit! 😆

You don’t need ‘lessons’ on being smooth, you just have to put a bit of thought into your riding, experiment and practice. It’s free and it’s fun. Folk often say they don’t have time to practice ‘skillz’ but i don’t buy that – any time on a bike can be practice time.

kerleyFree MemberPosted 7 years agobut I’d still be interested to know whether much tougher rims are available, and why can’t they be done in step

A tougher rim could be made my just using more alu in the construction without caring about weight (In fact you could pick already available tougher rims than you have been using, isn’t a WTB Laser Disc an XC rim for example?) Steel would still not be a better material as it would just be heavier for the same strength.

Why does nobody make a heavy steel rim (that would rust), simple answer – because very few people would actually buy one

gaidongFree MemberPosted 7 years ago@Kerley, the WTB Laser Discs were as stock on an steel XC hardtail. I have a 160mm full sus now, and surely DT’s E-series wheels should be strong enough. As a solid unit of material even bog standard steel is far stronger, stiffer and harder than aluminium, the issue is we’re dealing with hollow volumes and shapes. In the Cotic Rocket explanation Cy talks about how steel’s density penalty is excessive for XC bikes but becomes viable for for heavier duty machines. Why can’t the same apply to wheels, especially (and I don’t know if these alloys are appropriate for wheels rather than tubes) when we have such grades as Reynolds 853, 931 and 953; the latter two of which are stainless and thus won’t rust (much, my road bike is 931 and if you really don’t look after it there can be some discolouration).

Look at chainrings, aluminium is a crazy material for that but now that SRAM is selling steel ones, at a vastly reduced cost, there should be a good market. I’ve got a WTC stainless one; slightly more expensive than most alu narrow-wide rings but vastly more durable.

There must be an engineering solution point at which steel’s strength, toughness and hardness outweigh its density.

cookeaaFull MemberPosted 7 years agoStrength to weight wise aluminium is the winner but tends more towards brittle rather than ductile failure, the steel we already use in wheels is used more for it’s tensile strength and even that gets pared down to the minimum…

Wheels are basically a mixture of materials and construction to give you a structure that balances weight against strength and cost.

Of course not all that long ago steel was the default rim material, the manufacturing technologies of the age basically worked around rolling sheet in to the desired shape and then either painting or plating it for corrosion resistance.

A lot of areas of manufacturing moved away from steel when aluminium became easier to use, extruded aluminium profiles deliver a better cross section for less weight, it requires a bit less energy to process aluminium (lower melting point) better heat treatment processes offset annealing / work hardening from forming and fabrication (although also impact that energy saving). Plating (anodising) aluminium is well understood and the finish is arguably better for corrosion protection.

The other thing to remember is that MTBs and frequently bashing rims into rocks is a relatively recent development, up until say ~40 years ago most rims were expected to be used on relatively smooth surfaces, the odd kerb edge or pot hole impact was an infrequent risk not too high up the agenda. ~25 years ago MTB specific rim profiles arrived, rather than manufacturers using a 559mm rolled touring rim profile.

However rim brakes were still the main way of stoppingn so the best available construction remained extruded aluminium profiles with flat sides. “modern” disc specific rims have only really been about for the last 15 years or so.And of course Composites are now making their way into wheel construction and giving all sorts of new possibilities and options for how a wheel is constructed and what sort of balance of weight/strength/costs can be achieved, I very much doubt anyone will choose to go back to steel just to achieve greater impact resistance for DH which is really a relatively niche application…

gaidongFree MemberPosted 7 years ago@cookeaa, thanks very much for that summary, in historical perspective. I follow your argument on specific strength (https://en.wikipedia.org/wiki/Specific_strength), which is listed here as c. 60 KYuri versus c. 200 for 7075 (though balsa is higher still!). But oh for some lovely cheap though slightly heavy impact resistant rims; maybe like a Zee as opposed to a Saint!

DelFull MemberPosted 7 years agoadded to which any weight gain at the rim is in the worst possible place.

wrap your rims in more air or more tyre or a combination of both. oh, and try to stop smashing them off stuff. 😀

OK – TBF the ‘pebbly’ scenario described could have been due to a tyre that had already lost air for all you know. the wtbs aren’t ( as far as i know, and i had some of those on my old 5 ) renowned for being particularly strong, and DTs were known for being prone to dents, though whether this still holds true for the ones you mention i do not know.

like all bike stuff, bontrager’s law applies. choose your poison.why the hell would anyone want a stainless hub!?

kerleyFree MemberPosted 7 years agoVery probably, but it may still end up with a rim that weighs much more than equivalent alu based rim and again a rim that nobody would buy (as 99% of people don’t have a problem with Alu or carbon rims)

cookeaaFull MemberPosted 7 years agoI suppose the real problem you have though is the nature of the failure OP, your rim took a heavy edge impact with enough force to overcome the cushioning/load spreading capacity of the tyre a similar edge impact on a steel rim would have a similar result unless you beefed the whole section up significantly, resulting in a very heavy rim…

The engineered solution already in place is about as good as you’re going to find with current materials, which is of course a modular construction system for wheels, that allows pretty much every component to be replaced if it suffers a failure including the rim…

I would call what you have there a “safe” failure in so much as the rim bore the impact, the damage remained local and the wheel didn’t collapse, (I assume you were able to come to some sort of controlled stop)…

Everything has its limits, make an indestructible rim and those stresses just get passed on to another part of the bike, so what do you want to break instead?

gaidongFree MemberPosted 7 years agoI just took the tyre off the Grail and the rim is folded right into the bed. So the rim wrecked but no actual visible damage to the body of the rim. The tyre didn’t flat somehow and I had to do another 35km on it with only a very slight loss of true…

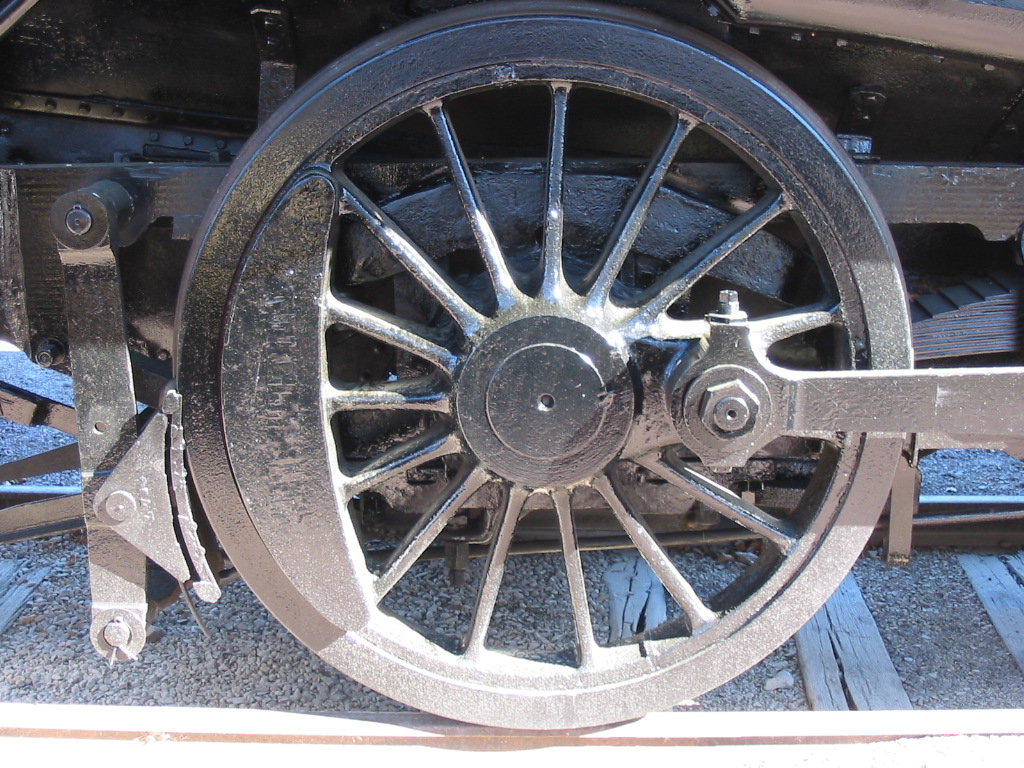

For the MTB, what I obviously need is a completely solid steel wheel, not rim, wheel! That looks like a 650b doesn’t it? 😀

epicycloFull MemberPosted 7 years agoghostlymachine – Member

I would think that to get the weight competitive the walls would be so thin you’d not be able to extrude a shape that complex, without going to some super exotic steel alloy….I was thinking about that the other day as I was building a new wheel with Wellworthy rims.

With the low pressures being used in plus size tyre these days, there could be whopping great holes in the rims. With formed edges they wouldn’t lose stiffness compared to without.

Before most of you were born my mountain cycling was done on steel rims because the alloy rims of the day were made of cheeseinium.

The steel rims were not invulnerable, but they could be bashed or bent back into shape trailside. I even carried a wee block of wood as a form for that very purpose and the adjustable spanner for wheel removal did the bending. (Riding rocky singletrack with 1?” tyres usually meant a ding every so often).

With fatter tyres and rolled edges, they would be quite usable. My stainless 700c Westrick steel rim weighs 750 gms so a fat tyre rim with holes wouldn’t weigh much more, and possibly with a higher grade of steel, maybe lighter.

As for braking, it wasn’t too bad with the red rubber pads*. I used Dunlop stainless steel rims which were etched on braking surface for better water dispersion.

*That’s relative of course. 🙂

dovebikerFull MemberPosted 7 years agoMy memory of steel rims involved Weinmann calipers that flexed alarmingly and squealing brake blocks that did relatively little in terms of decreasing velocity – good riddance!

MosesFull MemberPosted 7 years agoIt’s not just a matter of weight, it’s to do with manufacturing techniques. Alu alloys can be extruded in complex, strong, sections and then bent into rims. That’s much nore difficult with steel and Ti because of their higher melting points and the way they change properties after heating / cooling.

epicycloFull MemberPosted 7 years agodovebiker – Member

My memory of steel rims involved Weinmann calipers that flexed alarmingly and squealing brake blocks that did relatively little in terms of decreasing velocity – good riddance!My rubber pads could lock the wheel, but that’s more of a commentary of the amount of grip the tyres had I suppose. I had GB Coureur 66 centre pull brakes, I don’t remember much flex other than in the levers and cables, but that is a very long time ago.

I wonder how well steel rims would stop with something like the material used on disk pads? Possibly too much flex in the brake surface to be any use.

gaidongFree MemberPosted 7 years ago@epicyclo, thanks very much for your comments. The capacity for repair is something like what I had in mind.

gaidongFree MemberPosted 7 years agoSeems like these guys have a range – http://www.rimsandrims.it/radaelli/en/home/servizi/ordina-il-tuo-cerchio/Dati-Ciclo/maincontenutoright/0/pdfFile/SANREMO%20RADAELLI%20-%20STEEL%20RIMS%20CATALOGUE.pdf

Bottom of that PDF they have bicycle rims and the ‘WO 38’ model in 26x 1 1/2 comes out at 584.4 mm diameter; so less than half a millimetre from 650b. You know, I’m almost tempted to try this just to be a difficult bugger 😀

kerleyFree MemberPosted 7 years agoSo when you dent the steel rim and squash the edge of the rim what are you hoping to be able to do?

Wouldn’t think you could easily reform the rim.Or are you thinking the hollow section of the steel rim would not dent because thin steel is so strong?

cookeaaFull MemberPosted 7 years agoIf you want to give it a whirl why not. I would be interested to hear how it goes, what sort of weight the rim/wheel build comes to and just how tough it is when you start ploughing the rock gardens…

The topic ‘Calling all engineers, why no high performance steel MTB rims?’ is closed to new replies.