- This topic has 22 replies, 10 voices, and was last updated 1 year ago by neilnevill.

-

Joineristists…ASSEMBLE!!!!!

-

thestabiliserFree MemberPosted 1 year ago

We’ve had an artisan bespoke handmade craftsperson custom kitchen made, get us. However the **** doors don’t shut. Triffic. A combo of warm in the annexe and additional paint but that should have been allowed for. Getting the bumbling shitwit who made them to make good isnt an option. Theyre in Norwich, were in Cumbria, so not happening…

Were looking at an overlap of a bawhair to 1mm in places. So what are my options…

1. Increase the depth of the hinge rebate

2. Plane the doors

3. Sand the doors

4. Burn the lot and murder a stranger, live a quiet life at her majesties pleasure?Help, please!

leffeboyFull MemberPosted 1 year agoPictures? It’s difficult to know but it will depend on where the problem is. Rejoice though, this could be an excuse to get some new tools. Silver linings etc

piemonsterFull MemberPosted 1 year agoCoincidentally ive just adjusted some cupboard door brackets as overlap had developed.

Id by a load of new tools just to be sure.

thestabiliserFree MemberPosted 1 year agoYeah they’re just plate hinges so no significant movement on them

kayak23Full MemberPosted 1 year agoGetting the bumbling shitwit who made them

Nice.

Did you ask for them to be made in actual wood, because wood moves. It happens.

Have anything made out of it and you have to accept that as a possibility. Even with frame and panel type construction.

Take a photo.kayak23Full MemberPosted 1 year agoThey’re inset doors and so are much more susceptible to problems if they move at all.

If the bumbling shitwit who made them had left a nice big gap all around to allow for any movement, you’d probably be dissing them too.They just need planing on the closing edge a little.

chickenmanFull MemberPosted 1 year agoFolk love seeing butt hinges as it looks like “proper” furniture but really why wouldn’t you use a frame fix sprung cabinet hinge? Self closing so no crappy magnetic catches, adjustment for when the top hinge inevitably sags over time and no horrible tiny screws into end grain if board material used for doors or frames.

leffeboyFull MemberPosted 1 year agoThey just need planing on the closing edge a little.

That. They look way to tight given how much wood expands during a year

And that hinge thing – use proper hinges

dyna-tiFull MemberPosted 1 year agoThey just need planing on the closing edge a little.

.An undercut* might work, but they still look too big. 2mm clearance all round would give room for expansion.

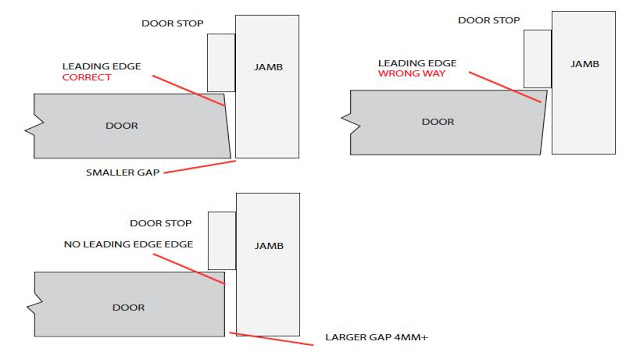

* Undercut.

The leading edge is planed at a slight angle. this allows the back edge to clear as it swings in an arc. It means the front edge of the door can have a really tight tolerance, but the side and back are simply not there to hinder the door fitting into the frame

eg

———————–

Cutting the hinges in further might cause more problems as the back edge of the door will impact into the frame.

Cabinet door hinges arent a cheap option, they can be of very good quality and are also found on kitchens costing tens of thousands.

Because the doors are painted, i’d suspect they’re made of mdf. If thats the case then there should be little to no seasonal movement. If it is wood, then the paint would protect it from seasonal changes to air moisture and again movement would be minimized.

Bottom line is he’s made a complete 4r5e of the doors. and its more than likely the cabinet carcass has moved slightly when it was being fitted.

I’d be on the phone looking for them to sort it not you. Besides, you get to hear the childish excuses they’ll come up with.

kayak23Full MemberPosted 1 year agoI don’t think we know any of that. The op implied they were fine initially, and also implied there was more to the story that prompted his description of the maker.

An awful lot of ‘posher’ kitchen doors are painted tulipwood in my experience, sapele even. Quite often because folks have this thing that solid wood is better. Not always the case.

What are they made from op?

Anyway, whatever they’re made from, it’s relatively simple to sort. Just a bit of a bugger when they’ve been painted but hey ho.

thestabiliserFree MemberPosted 1 year agoThey’re beech and mdf centre panels and they were snug on delivery but in the heat must have swelled. There are a number of reasons why I won’t be asking the supplier back to sort, not least of which is I simply don’t trust him to do it right

kayak23Full MemberPosted 1 year agoThey’re beech and mdf centre panels and they were snug on delivery but in the heat must have swelled. There are a number of reasons why I won’t be asking the supplier back to sort, not least of which is I simply don’t trust him to do it right

Fair enough, and you’re not telling us everything but, as I said above, anything made from wood is subject to movement which can be exacerbated by certain conditions.

I always worry, my workshop being unheated, when I go and plonk things into centrally heated houses that some people have at crazy temperatures.You of course have to design movement in and if you know anything about woodworking you’ll do this by default but you can’t always prevent every potential issue.

If someone comes back to me with any issue like this(they haven’t yet), I’ll go out of my way to sort it, but I also let them know from the start that things like this can and do happen.

Not sure why your relationship with the maker has gone sour, but I know that sometimes people can have unrealistic expectations of natural materials.

As I say, if you leave a big gap (‘big’ being rather subjective here) from the start, then folks might accuse you of being cack handed. Hard to win sometimes.

dyna-tiFull MemberPosted 1 year agoAre you getting wood shavings ?. or dust ?

I could be wrong but thought it was mdf. A back piece, with the frame ‘overlaid’ on to give the effect of a framed door.

If its timber and due to movement, the joints could crack(sorry to be the harbinger of doom 😆 ) well not crack seriously, just the finish. mdf, which has no movement you can 2 pack fill the joins so you get that nice clean painted finish you have on it.

pk13Full MemberPosted 1 year agowood moves suck it up princess..

joke……

beach is stable tbh don,t take too much off the doors they might shrink if the timber was not dry before paint?

are the panels glued in or lose? i make them sung fit with no glue if rebated in, you get a bit of movement wiggle room.

also have you made sure the door opening are all plumbed uptimbaFree MemberPosted 1 year agoDon’t paint just yet, let everything settle. Remember that as one door closes another one opens, well it does if you get the gaps wrong 🙂

neilnevillFree MemberPosted 1 year agoAn example of how much wood expands, I’ve 2 Ercol sideboards where the doors won’t close for maybe 6-8 months of the year. Styling looks great, when they shut, the rest of the time I definitely appreciate that a larger gap around the door would be a very good thing.

You must be logged in to reply to this topic.